Preparation method of far infrared tile

A far-infrared, ceramic tile technology, used in manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., to achieve the effect of improving quality, strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention, and in the absence of conflict, the present invention The embodiments and the features in the embodiments can be combined with each other.

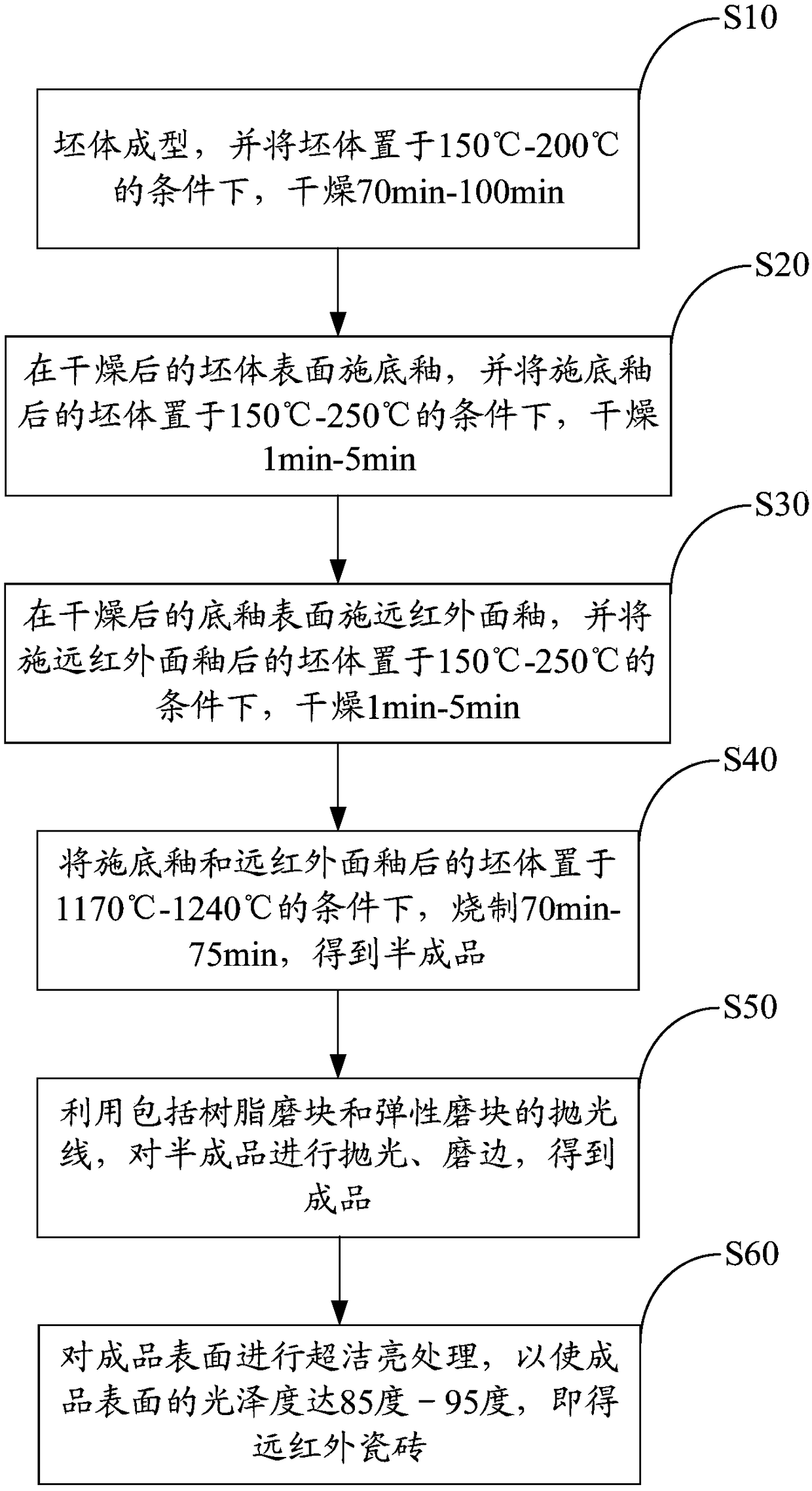

[0033] Such as figure 1 Shown, the present invention proposes a kind of preparation method of far-infrared ceramic tile, comprises the following steps:

[0034] Step S10, molding the green body, placing the green body at a temperature of 150°C-200°C, and drying the green body for 70min-100min;

[0035] Step S20, applying a primer on the surface of the dried body, and placing the primer body under the condition of 150°C-250°C, and drying for 1min-5min;

[0036] Step S30, applying a far-infrared top glaze on the surface of the dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com