Antibacterial warm-keeping anti-electromagnetic radiation textile fabric and preparation method thereof

A technology for anti-electromagnetic radiation and textile fabrics, applied in textiles, papermaking, fiber processing, etc., can solve the problems of poor electromagnetic radiation shielding effect, stiff hand feeling, loss of air permeability, etc., achieve good air permeability, reduce production costs, and reduce agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

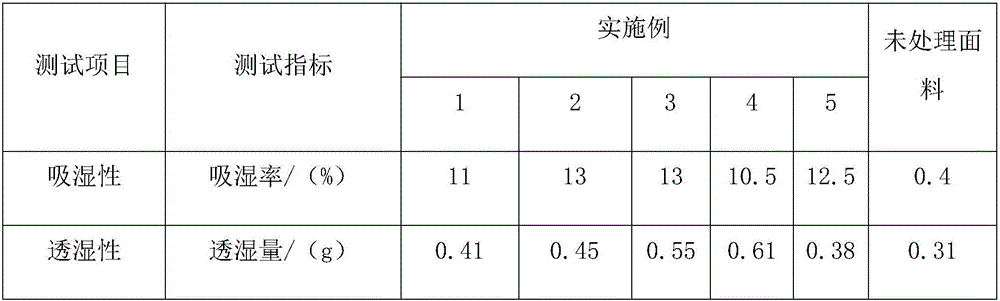

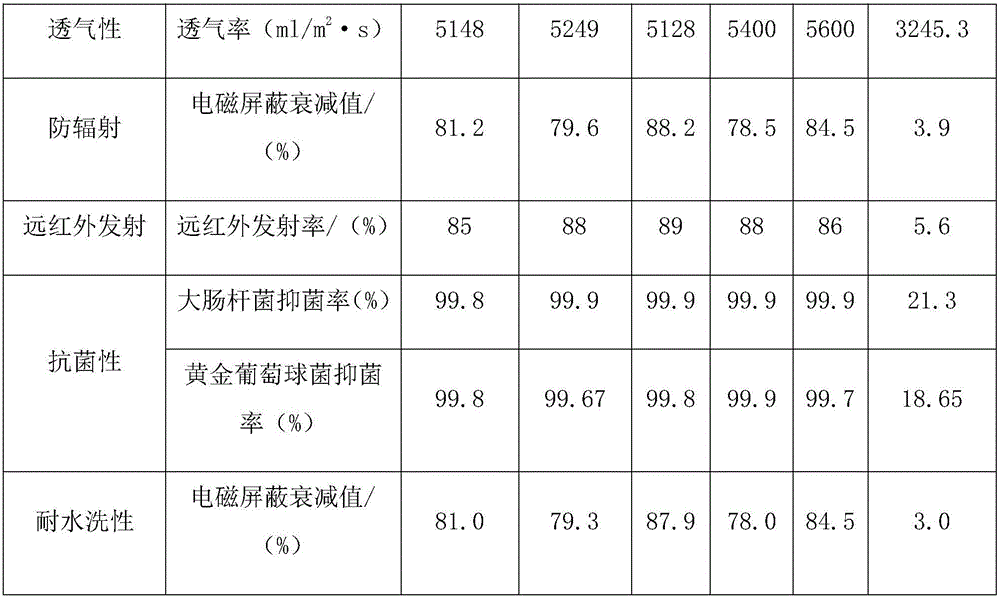

Examples

Embodiment 1

[0027] The preparation method of the antibacterial warm-keeping anti-electromagnetic radiation textile fabric mainly comprises the following method steps: S1: the preparation of multifunctional impregnating liquid: (1) the multifunctional impregnating liquid is mainly composed of the following raw materials by weight, 65 parts of deionized water, nano-titanium dioxide 3.5 parts, 1 part of nano-cerium oxide, 3 parts of nano-silicon carbide, 0.5 parts of metal-loaded carbon nanotubes, 2 parts of nano-titanium carbide, 4 parts of nano-zinc oxide, 1 part of nano-ferric oxide, 1 part of bamboo charcoal, metal / graphite 1 part of alkene, 2 parts of nano-zirconia, 1 part of nano-silicon nitride, 1 part of nano-nickel oxide, 1 part of nano-ferric oxide, 1 part of barium sulfate, 1 part of silver chloride, 1 part of tourmaline, 10 parts of ionic liquid - part, 1 part of surface treatment agent, 1 part of dispersant, 1 part of additive; (2) add ionic liquid, surface treatment agent, dispe...

Embodiment 2

[0035]The method for preparing an antibacterial, warm-keeping and anti-electromagnetic radiation textile fabric is characterized in that it mainly includes the following method steps: S1: preparation of a multifunctional impregnation solution: (1) the multifunctional impregnation solution is mainly composed of the following raw materials in parts by weight, deionized water 70 6.8 parts of nano-titanium dioxide, 4 parts of nano-cerium oxide, 10 parts of nano-silicon carbide, 3 parts of metal-loaded carbon nanotubes, 6 parts of nano-titanium carbide, 5 parts of nano-zinc oxide, 3 parts of nano-ferric oxide, and 2 parts of bamboo charcoal , 2 parts of metal / graphene, 5 parts of nano-zirconia, 2 parts of nano-silicon nitride, 5 parts of nano-nickel oxide, 2 parts of nano-ferric oxide, 5 parts of barium sulfate, 5 parts of silver chloride, 4 parts of tourmaline , 20 parts of ionic liquid, 10 parts of surface treatment agent, 10 parts of dispersant, 5 parts of additive; (2) add ionic...

Embodiment 3

[0044] The method for preparing an antibacterial, warm-keeping and anti-electromagnetic radiation textile fabric is characterized in that it mainly includes the following method steps: S1: Preparation of a multifunctional impregnation solution: (1) The multifunctional impregnation solution is mainly composed of the following raw materials in parts by weight, deionized water 67 4.1 parts of nano-titanium dioxide, 2 parts of nano-cerium oxide, 5 parts of nano-silicon carbide, 0.8 parts of metal-loaded carbon nanotubes, 3 parts of nano-titanium carbide, 4.1 parts of nano-zinc oxide, 1.5 parts of nano-ferric oxide, and 1.4 parts of bamboo charcoal , 1.3 parts of metal / graphene, 2.2 parts of nano-zirconia, 1.1 parts of nano-silicon nitride, 1.5 parts of nano-nickel oxide, 1.1 parts of nano-ferric oxide, 2 parts of barium sulfate, 2.2 parts of silver chloride, 2 parts of tourmaline , 15 parts of ionic liquid, 2 parts of surface treatment agent, 3 parts of dispersant, 2 parts of addit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com