High-strength self-healing material and preparation method thereof

A high-strength, composite material technology, applied in the field of biomass-based functional materials, achieves the effects of simple preparation methods, overcoming low strength, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation of embodiment 1 functional polyamide 1

[0032] Take 100 parts by weight of functional polyamide monomer 1, and 1 part by weight of the second-generation Hoveyda-Grubbs catalyst. Put it into an oil bath at 60°C, and react for 24 hours under the condition of oil pump vacuum to obtain a high-strength self-healing material composed of functional polyamide 1. The specific reaction equation is as follows:

[0033]

[0034] Figure 5 It is the transmission electron microscope picture in Example 1, from which it can be seen that the functional polyamide 1 prepared in Example 1 has a uniformly distributed crystal structure, and most of the crystal sizes are between 30 and 35 nanometers. This result clearly shows the internal microstructure of Example 1, which also confirms the design principle of the present invention, that is, the functional polyamide is designed with rigid nanocrystalline regions, thereby greatly increasing the mechanical properties of th...

Embodiment 2

[0035] The preparation of embodiment 2 functional polyamide 2

[0036] Its preparation method is the same as that of Example 1, except that the functional polyamide monomer selected is Monomer 2. The specific reaction equation is as follows:

[0037]

Embodiment 3

[0038] The preparation of embodiment 3 functional polyamide 3

[0039] Its preparation method is the same as that of Example 1, except that the functional polyamide monomer selected is Monomer 3. The specific reaction equation is as follows:

[0040]

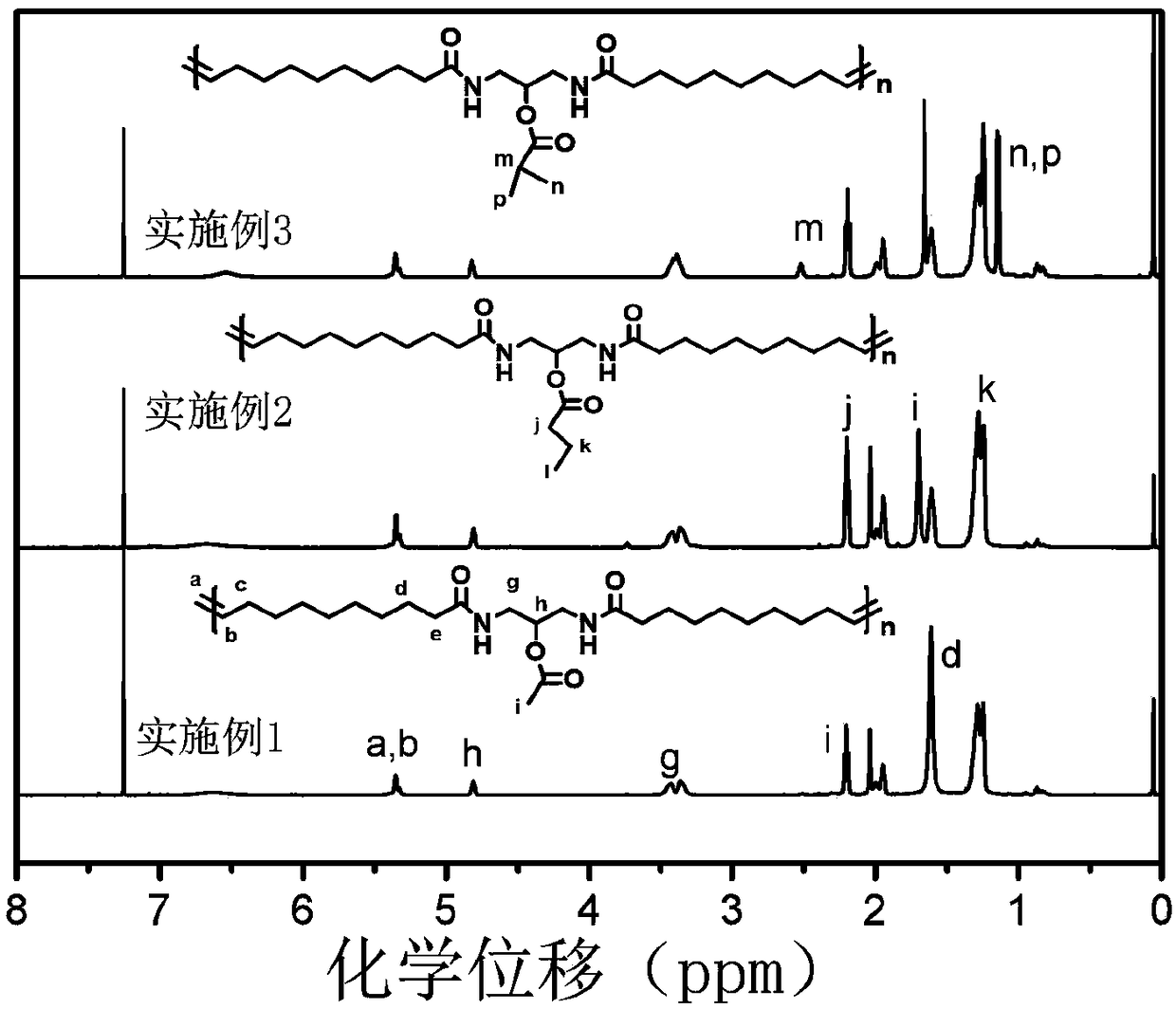

[0041] Such as figure 1 Shown: the amide groups, side chain groups and double bond characteristic peaks of the functional polyamides prepared in Example 1, Example 2 and Example 3 were all characterized in the H NMR spectrum, proving that the monomers were successfully polymerized to form a polymer things.

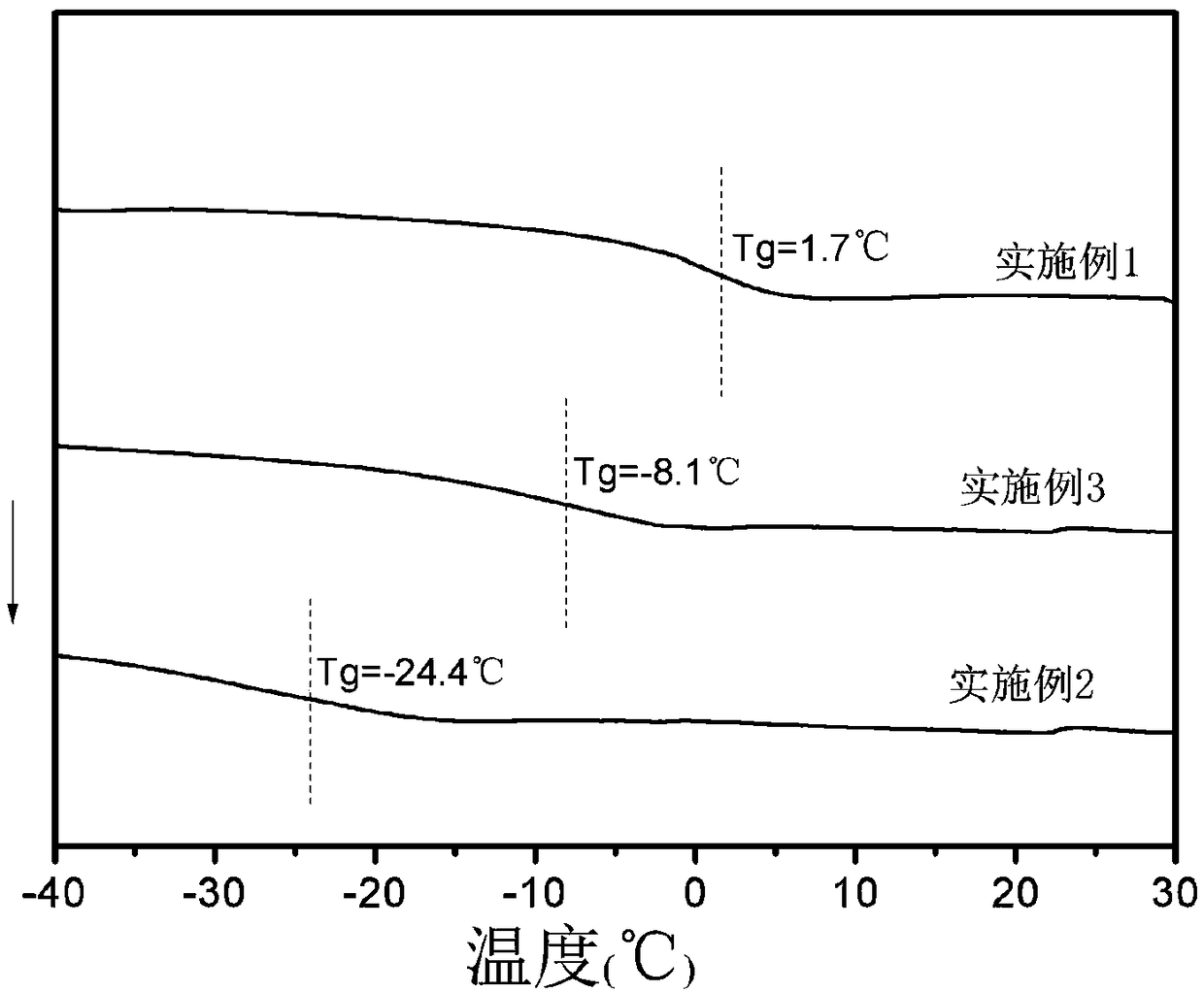

[0042] Through differential scanning calorimeter test (DSC test), figure 2 It shows that the glass transition temperatures of the functional polyamides prepared in Example 1, Example 2 and Example 3 are 1.7°C, -24.4°C and -8.1°C, respectively. From the low glass transition temperature, it is verified that this kind of functional polyamide has excellent self-healing properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com