Active supramolecular polymer and preparation method thereof

A supramolecular polymer and polymer technology, applied in the field of active supramolecular polymers and their preparation, can solve the problems of not observing the characteristics of active supramolecular polymerization, not using active supramolecular polymerization, etc., and achieving rich chemical components, Strong luminous properties, size controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0092] In some cases, the preparation method of the present invention further includes a step of constructing aligned metal nanoparticles or nanowires using the formed supramolecular polymer as a precursor.

[0093] The supramolecular polymerization method in the present invention generally comprises at least two components: a planar or linear solvent-repellent small molecule component and a solvent-friendly polymer component. In embodiments performed in aqueous solution, the planar or linear small molecule components are hydrophobic and the polymer components are hydrophilic. Non-covalent interactions between small molecules include but are not limited to metal-metal interactions, π-π interactions, hydrogen bonds, solvent-phobic interactions, or combinations thereof, and supramolecular polymerization is induced by non-covalent interactions between small molecules to promote the growth of supramolecular polymers. The polymer components act to stabilize the formed supramolecul...

Embodiment 1

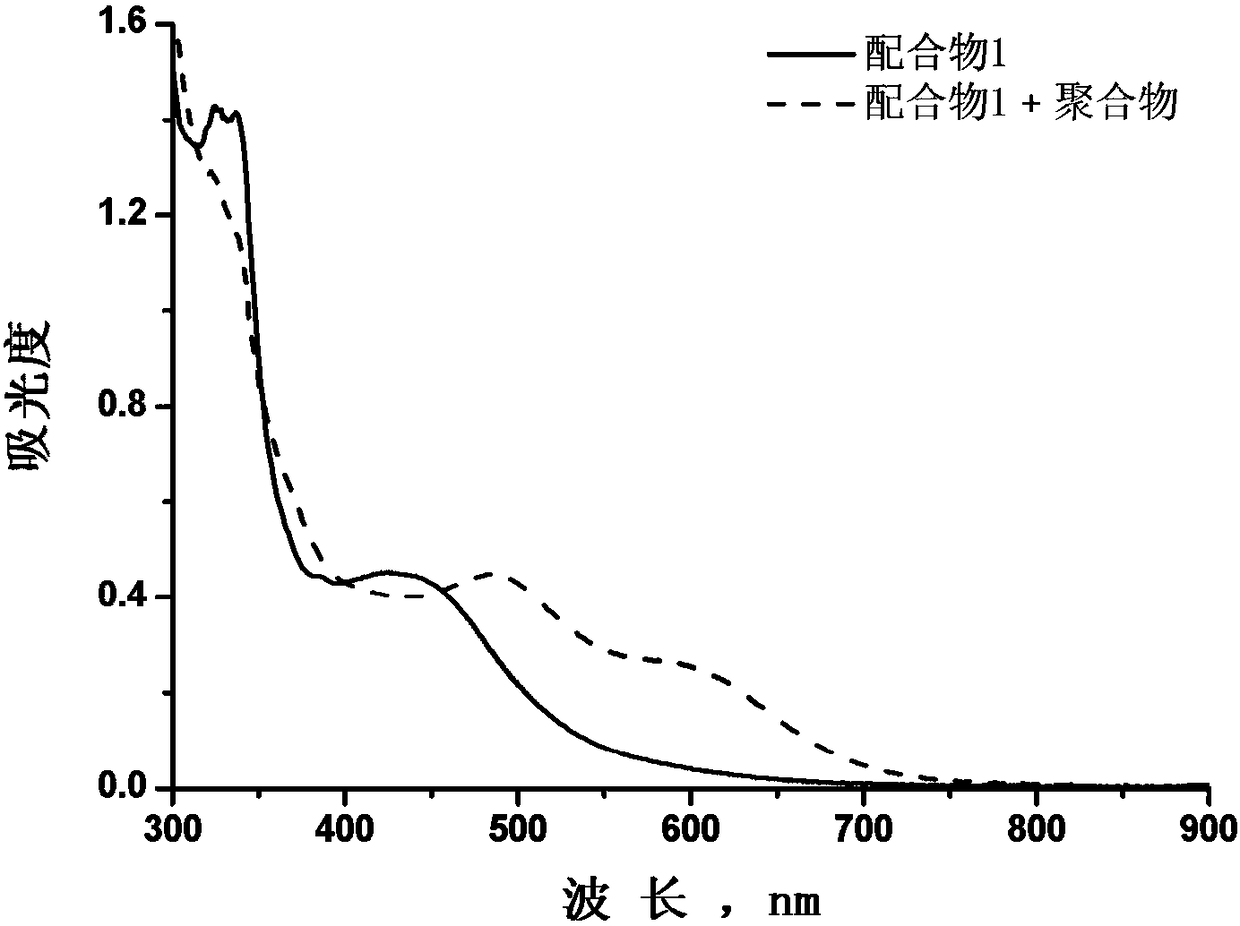

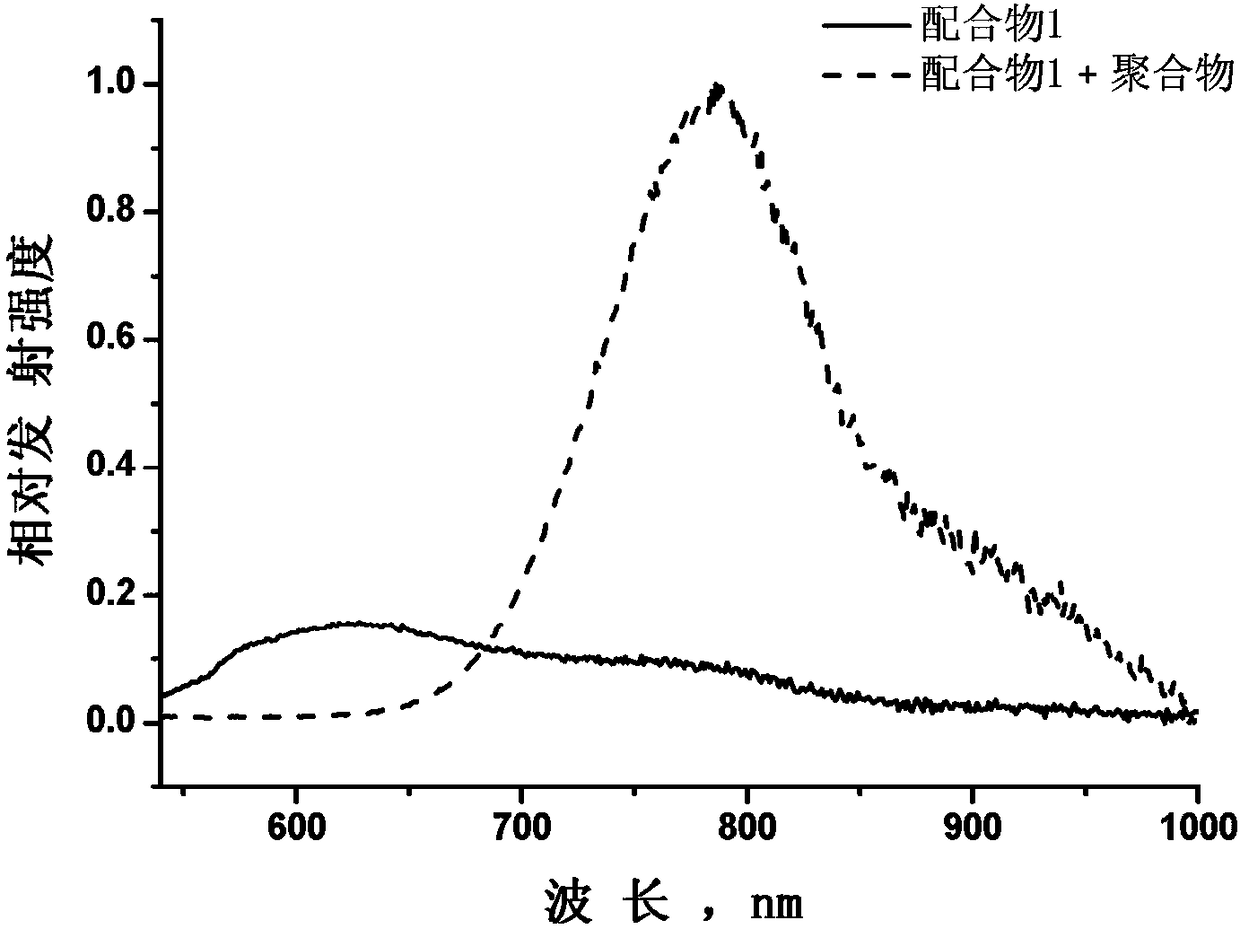

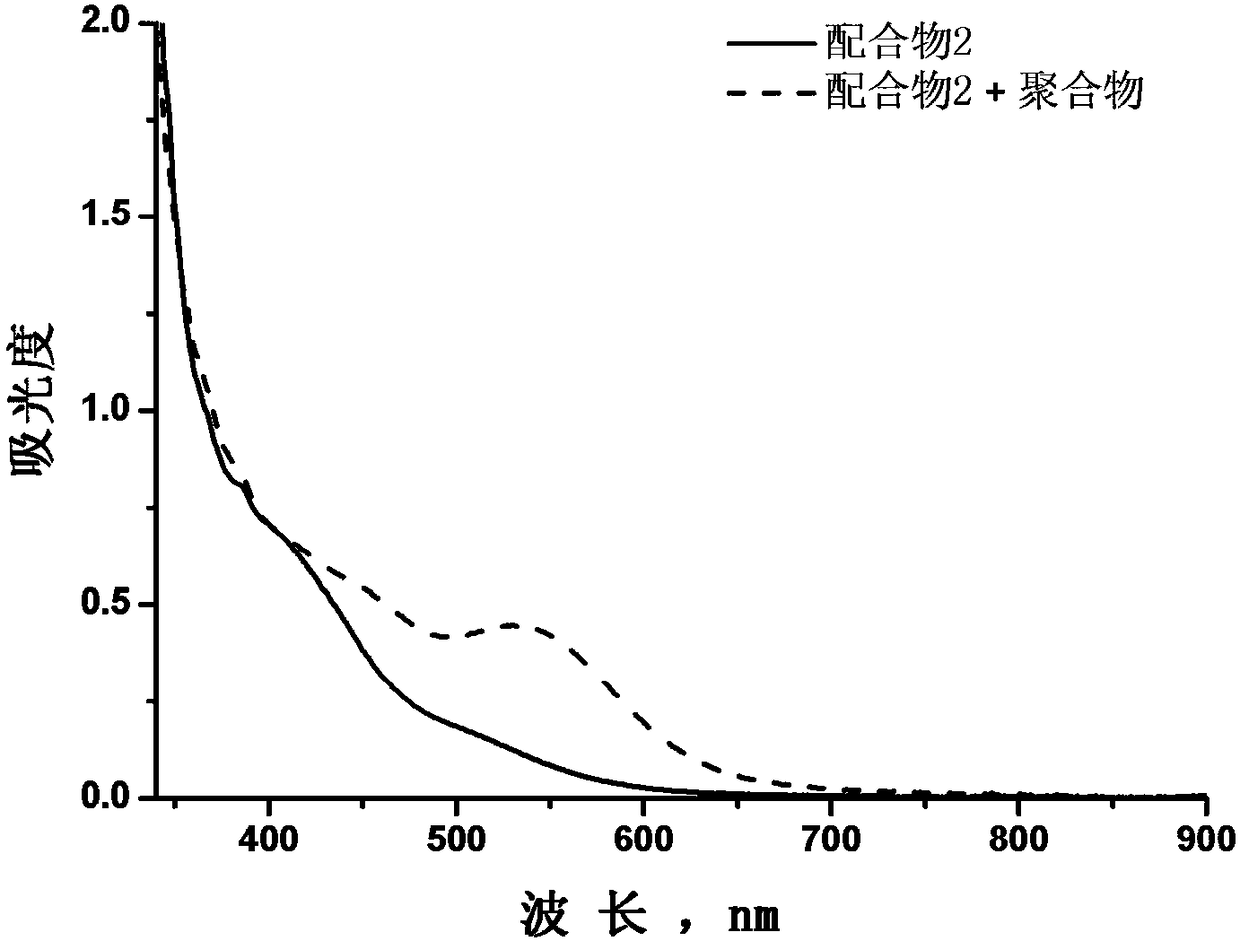

[0227] Example 1. Complex 1 and PEG 45 -b-PAA 69 The two-component supramolecular polymerization (see No. 1 in Table 1)

[0228] Compound 1 (0.15mM) and PEG 45- b-PAA 69 (The subscript represents the degree of polymerization of each block, and the concentration of carboxylic acid is 1 mM). After mixing in an aqueous solution, and incubating at room temperature for 1 day, a supramolecular polymer can be obtained. The pH of the mixed solution was 5, the PAA block was negatively charged due to partial carboxyl deprotonation, and there was an electrostatic attraction between the positively charged complex 1 and PAA.

[0229] Transmission electron microscope observation found that the prepared two-component supramolecular polymer is a nanofiber with an average diameter of 10 nm and a length of several microns ( Figure 10 ). As a control, a solution of complex 1 alone and PEG alone 45 -b-PAA 69 None of the solutions formed nanofibers.

[0230] The EDX energy spectrum of TEM...

Embodiment 2

[0233] Example 2. Complex 1 and PEG 45 -b-PAA 69 Research on the process of two-component supramolecular polymerization (see No. 1 in Table 1)

[0234] Transmission electron microscope observation found that complex 1 and PEG 45 -b-PAA 69 Aggregates with a size of about 10 nm ( Figure 13 ). After incubation at room temperature for 1 hour, nanofibers were formed, and the average diameter of the nanofibers was 10 nm, and the average length was 440 nm ( Figure 14 ). After 12 hours, the length of the nanofibers grew to the micrometer level ( Figure 15 ). After 1 day of cultivation, the average diameter of the nanofibers was still 10 nm, and the length was several microns ( Figure 10 ). The length of the nanofibers increased with incubation time, but the average diameter remained constant. In view of the fact that nanofibers have a nanocrystal structure in which complexes are arranged in an orderly manner, the two-component supramolecular polymerization of complexes a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com