Silver nanowire conductive ink for screen printing and preparation method thereof

A silver nanowire and conductive ink technology, applied in the field of printing ink, can solve the problems of difficult cleaning of printing stencils, unfavorable recycling, environmental pollution, etc., and achieve the effects of low cost, uniform printing, and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

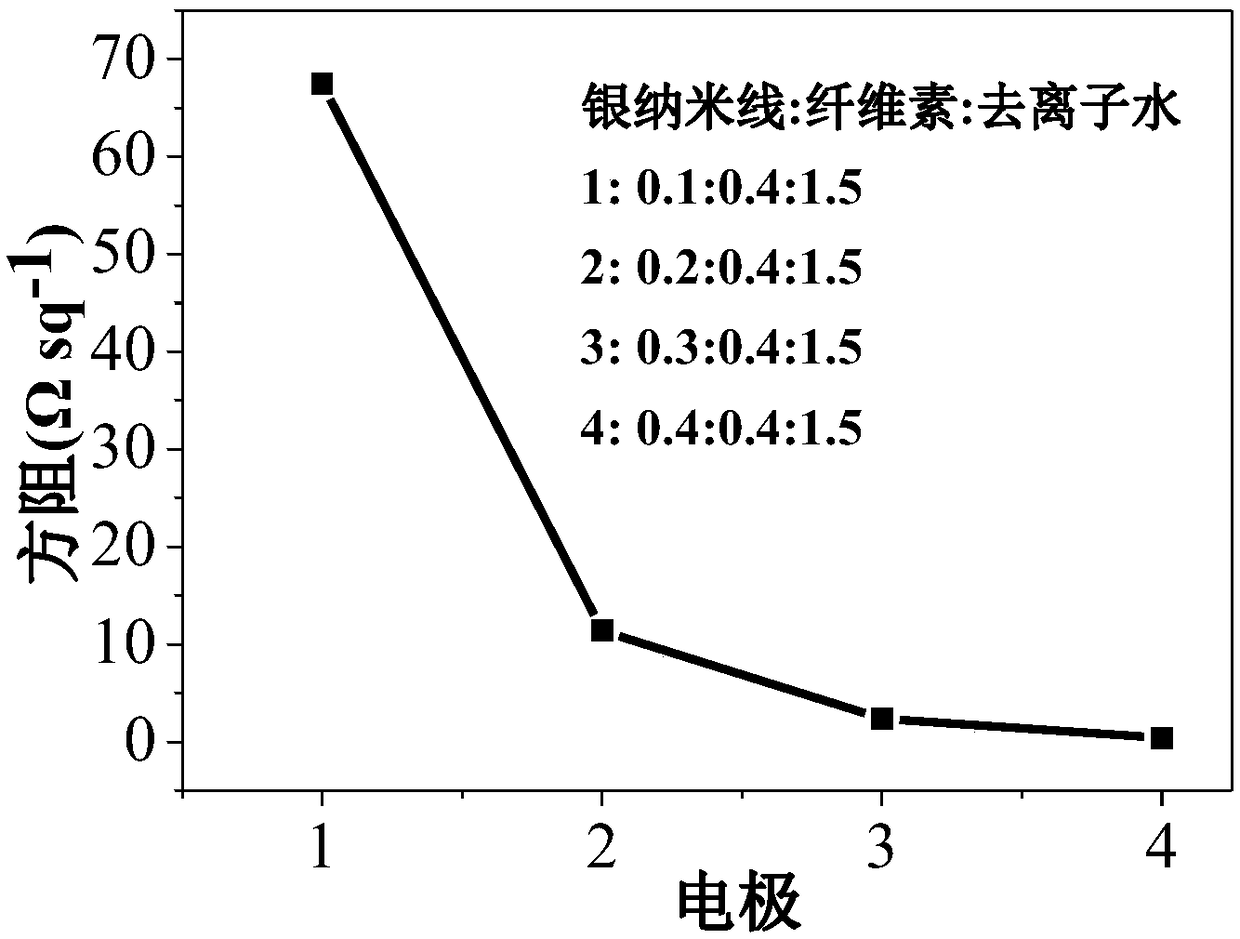

[0029] First, take 400 mg of hydroxypropyl methylcellulose and add deionized water, stir until the cellulose is completely dissolved to form a uniform solution. Then add the ethanol dispersion of silver nanowires to the aqueous solution of hydroxypropyl methylcellulose (the quality of silver nanowires contained in the solution is 100mg), heat and stir at 60°C until completely dry; finally add a defoamer (0.1g) , surfactant (0.1g), propylene glycol (0.1g), water (1.5g), mechanically stirred to form uniformly dispersed ink. The square resistance comparison chart of the printed pattern is attached to the instruction manual figure 1 shown.

Embodiment 2

[0031] First, take 400 mg of hydroxypropyl methylcellulose and add deionized water, stir until the cellulose is completely dissolved to form a uniform solution. Then add the ethanol dispersion of silver nanowires to the aqueous solution of hydroxypropyl methylcellulose (the quality of silver nanowires contained in the solution is 200mg), heat and stir at 60°C until completely dry; finally add a defoamer (0.1g) , surfactant (0.1g), propylene glycol (0.1g), water (1.5g), mechanically stirred to form uniformly dispersed ink. The square resistance comparison chart of the printed pattern is attached to the instruction manual figure 1 shown.

Embodiment 3

[0033] First, take 400 mg of hydroxypropyl methylcellulose and add deionized water, stir until the cellulose is completely dissolved to form a uniform solution. Then add the ethanol dispersion of silver nanowires to the aqueous solution of hydroxypropyl methylcellulose (the quality of silver nanowires contained in the solution is 300mg), heat and stir at 60°C until completely dry; finally add a defoamer (0.1g) , surfactant (0.1g), propylene glycol (0.1g), water (1.5g), mechanically stirred to form uniformly dispersed ink. The square resistance comparison of the printed pattern is shown in the attached manual figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com