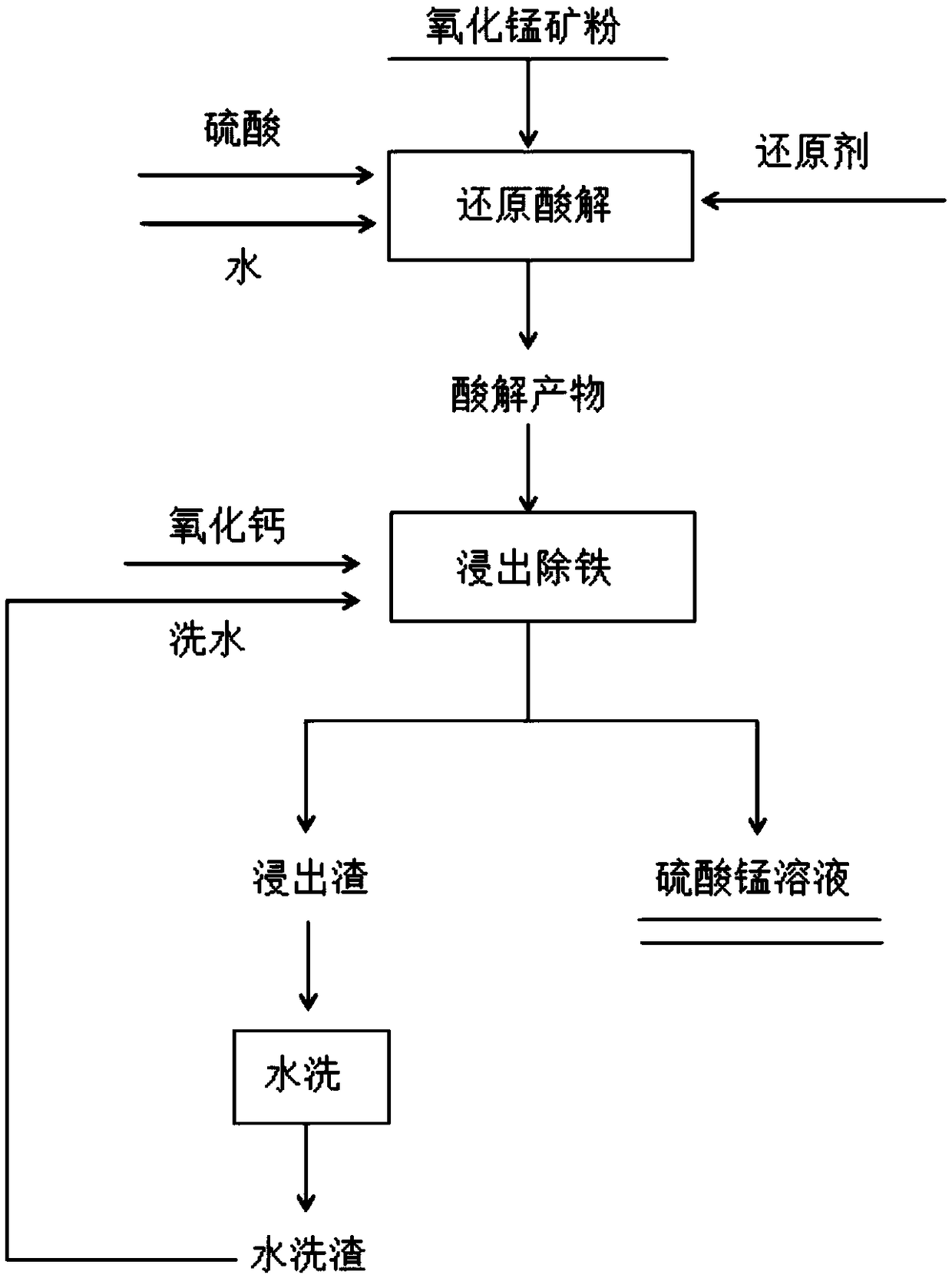

Method for carrying out reduction acidolysis-leaching and simultaneously removing iron to treat oxidized manganese ore

A technology for iron removal treatment and manganese ore oxidation, which is applied in the field of manganese metallurgy, can solve the problems of high leaching temperature and long time, and achieve the effects of increasing energy consumption, simplifying operation, and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The grade of manganese in the selected ore sample is about 20%, and the mass fraction of the ore crushed to less than 75 μm is not less than 85%. The reducing agent wood chips are obtained from local wood processing factories.

[0028] During reductive acid hydrolysis, firstly mix mineral powder and sawdust, then add water and concentrated sulfuric acid, stir well and put it in an incubator for aging for 14 hours. When feeding, the reducing agent / manganese ore mass ratio is controlled, the sulfuric acid / manganese ore mass ratio and the water / mineral ratio (ml / g) are respectively 0.3, 0.8, and 0.5.

[0029] Goethite method is used to remove iron during leaching and iron removal simultaneously. Mix the acid hydrolyzed material and calcium oxide thoroughly first, then add them to water in batches, control the pH of the solution to 2.5, stir and leaching at 90°C for 1.5h, the stirring speed is 300rpm, and the leaching liquid-solid ratio is 4. After leaching, solid-liquid ...

Embodiment 2

[0031] The manganese content in the selected ore sample is about 25%, and the mass fraction of the ore crushed to less than 75 μm is not less than 95%. The reducing agent wood chips are obtained from local wood processing factories.

[0032] During reductive acid hydrolysis, the ore powder and straw are fully mixed, and then water and concentrated sulfuric acid are added in sequence to control the mass ratio of reducing agent / manganese ore. The mass ratio of sulfuric acid / manganese ore and the water / mineral ratio (ml / g) are 0.35, 1.0, 1.0. After fully stirring, place it in a sealed box to age for 18 hours.

[0033] Goethite method is used to remove iron during leaching and iron removal simultaneously. First mix the acid hydrolyzed material and calcium oxide, then add it to water in batches, control the pH of the solution to 2.8, stir and leach at 95°C for 2 hours, the stirring speed is 300rpm, and the leaching liquid-solid ratio is 6. After leaching, solid-liquid separation...

Embodiment 3

[0036] The manganese content in the selected ore sample is about 25%, and the ore is crushed to a size smaller than 75 μm. The reducing agent wood chips are obtained from local wood processing factories.

[0037] During reductive acid hydrolysis, a certain amount of ore powder and sawdust are first mixed, then water and concentrated sulfuric acid are added in sequence to control the reducing agent / manganese ore mass ratio, the sulfuric acid / manganese ore mass ratio and the water / mineral ratio (ml / g) are respectively 0.4, 0.9, 0.8. After fully stirring, place it in an incubator to age for 16 hours.

[0038] Goethite method is used to remove iron during leaching and iron removal simultaneously. Mix the acid hydrolysis material and calcium oxide thoroughly first, then add them into water in batches, control the pH=2.6, stir and leach at 95°C for 2 hours, the stirring speed is 300rpm, and the leaching liquid-solid ratio is 5. After leaching, solid-liquid separation is carried o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com