In-situ preparation method and applications of coastal petroleum polluted soil repairing agent

A soil remediation agent and oil pollution technology, which is applied in the field of in-situ preparation of coastal oil-contaminated soil remediation agents, can solve the problems of high cost and limit the large-scale application of bio-enhancement technology, and achieves low cost, abundant sources and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

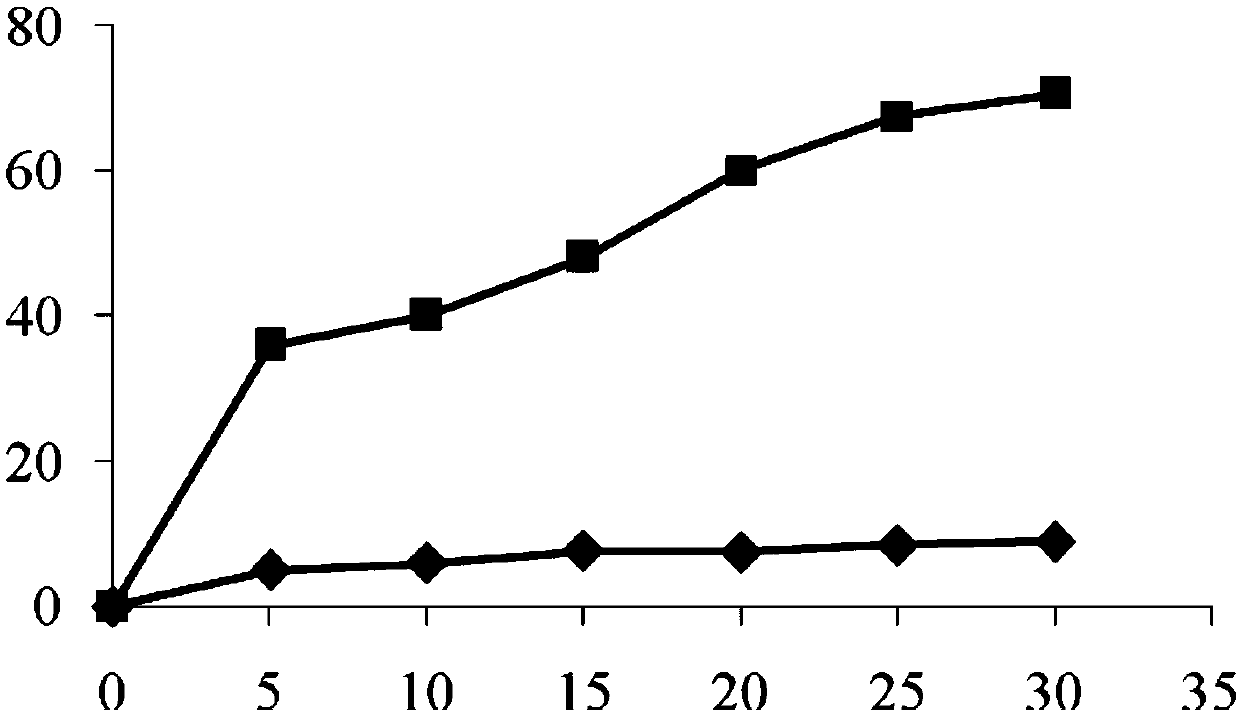

Image

Examples

Embodiment 1

[0024] (1) Preparation of seaweed lysate

[0025] Collect kelp from the offshore, remove the surface sediment, transport it to the oil-contaminated soil, chop it in situ, mix it with water at a material-to-liquid ratio of 1:30, add it to the hydrothermal reactor, and control the temperature of the hydrothermal reactor to 160°C. The reaction time is 2 hours, and the hydrothermal cracking product is obtained; the hydrothermal cracking product obtained above is subjected to solid-liquid separation, and the precipitate is recovered, and the liquid phase part is the seaweed cracking solution;

[0026] (2) In situ preparation of restoration agent

[0027] Get the petroleum-contaminated soil on the surface, and after pulverizing, separate through a 100-mesh sieve to obtain the part through the sieve; the seaweed lysate obtained in step (1) is divided into two parts of equal volume, one part of which is added to the part through the sieve, Adjust the solid-liquid mass ratio to 0.8:10...

Embodiment 2

[0031] (1) Preparation of seaweed lysate

[0032] Collect kelp from the offshore, remove the surface sediment, transport it to the oil-contaminated soil, chop it in situ, mix it with water at a material-to-liquid ratio of 1:20, add it to the hydrothermal reactor, and control the temperature of the hydrothermal reactor to 180°C. The reaction time is 1.5 hours, and the hydrothermal cracking product is obtained; the hydrothermal cracking product obtained above is separated from solid and liquid, and the precipitate is recovered, and the liquid phase is the seaweed cracking solution;

[0033] (2) In situ preparation of restoration agent

[0034] Get the petroleum-contaminated soil on the surface, and after pulverizing, separate through a 100-mesh screen to obtain the part that passes through the screen; the seaweed lysate obtained in step (1) is divided into two parts of equal volume, one part of which is added to the part that passes through the screen, Adjust the solid-liquid m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com