Method of biosynthesizing nanometer tellurium by utilizing bacillus licheniformis and application of method

A Bacillus licheniformis, biosynthetic technology, applied in microorganism-based methods, biochemical equipment and methods, nanotechnology for materials and surface science, etc., to achieve a wide range of applications, avoid secondary pollution, and good biosafety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

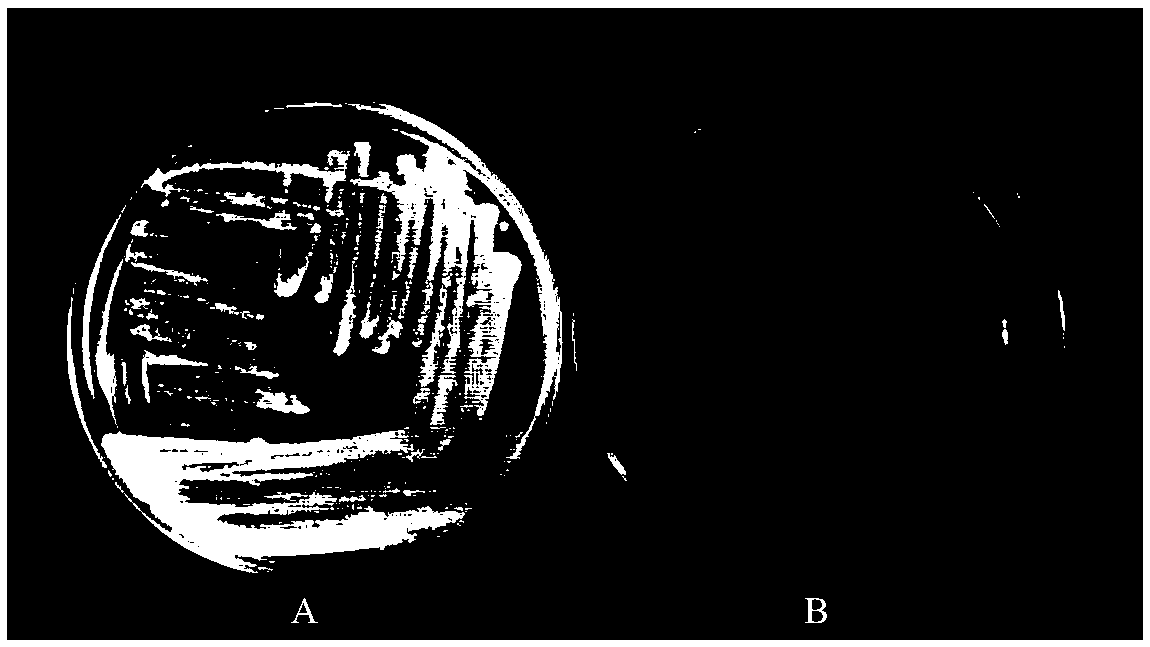

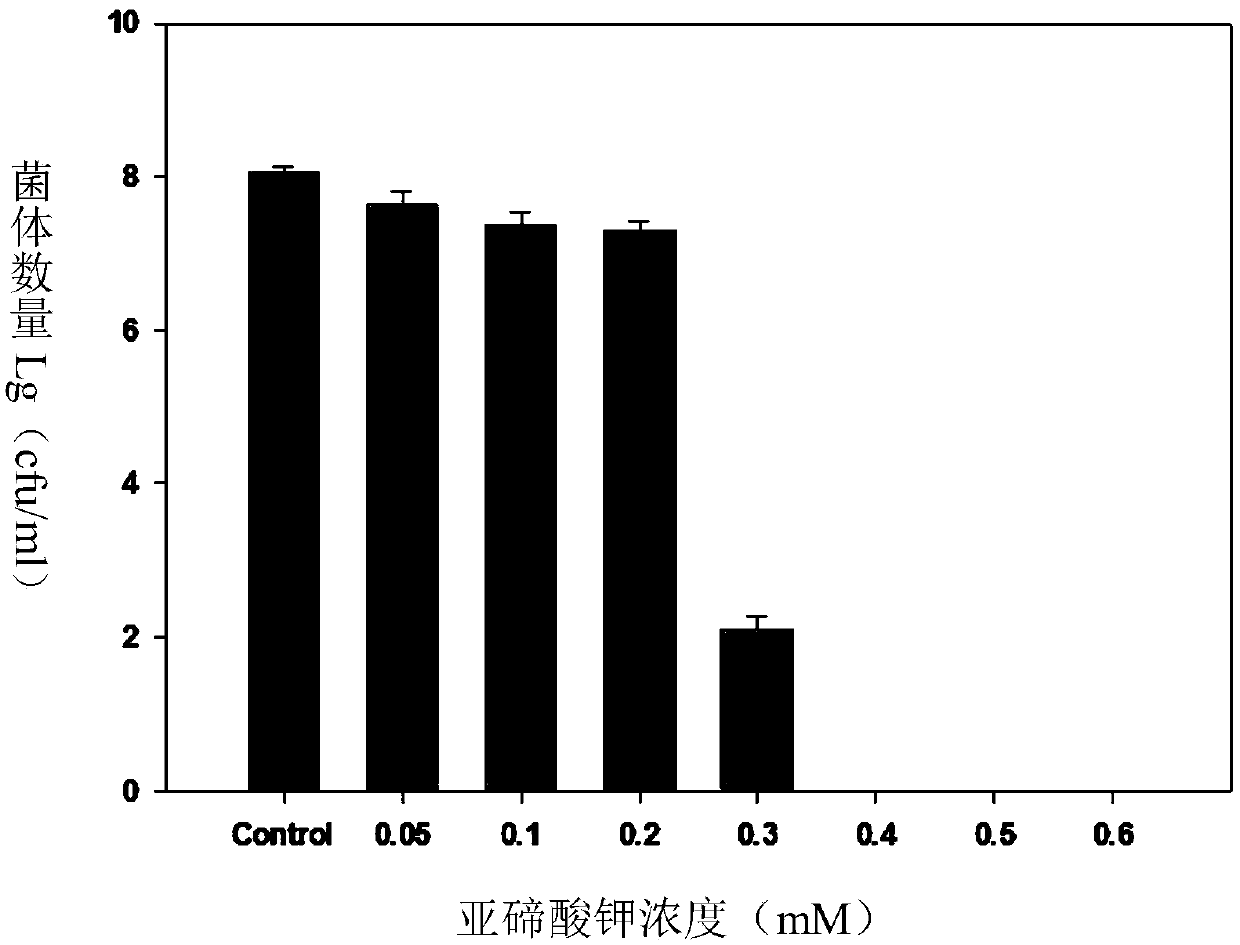

[0050] Embodiment 1 Bacillus licheniformis S13 is to the tolerance concentration of tellurite

[0051] 1. Prepare solid LB with different concentrations of tellurium-containing medium (each liter of medium contains 10g of NaCl, 10g of tryptone, 5g of yeast extract, 15g of agar, and 1L of deionized water), and autoclave at 121°C for 20 minutes; prepare tellurite The mother liquor (0.2M) was sterilized by filtration, and a tellurite solution was added to make the contents of tellurite in the medium respectively 0.05mM, 0.1mM, 0.2mM, 0.3mM, 0.4mM, 0.5mM, and 0.6mM.

[0052] 2. Pick a single colony of the S13 strain and inoculate it in LB liquid medium for shaking culture for 12 hours (150rpm, 37°C) to take the above bacterial solution and dilute it to OD 600 =0.8 mother solution for later use; drop 100 μL of the mother solution on plates containing different tellurium concentrations and spread evenly on the plate, each concentration has 6 replicates, culture at 37°C for 48 hours, a...

Embodiment 2

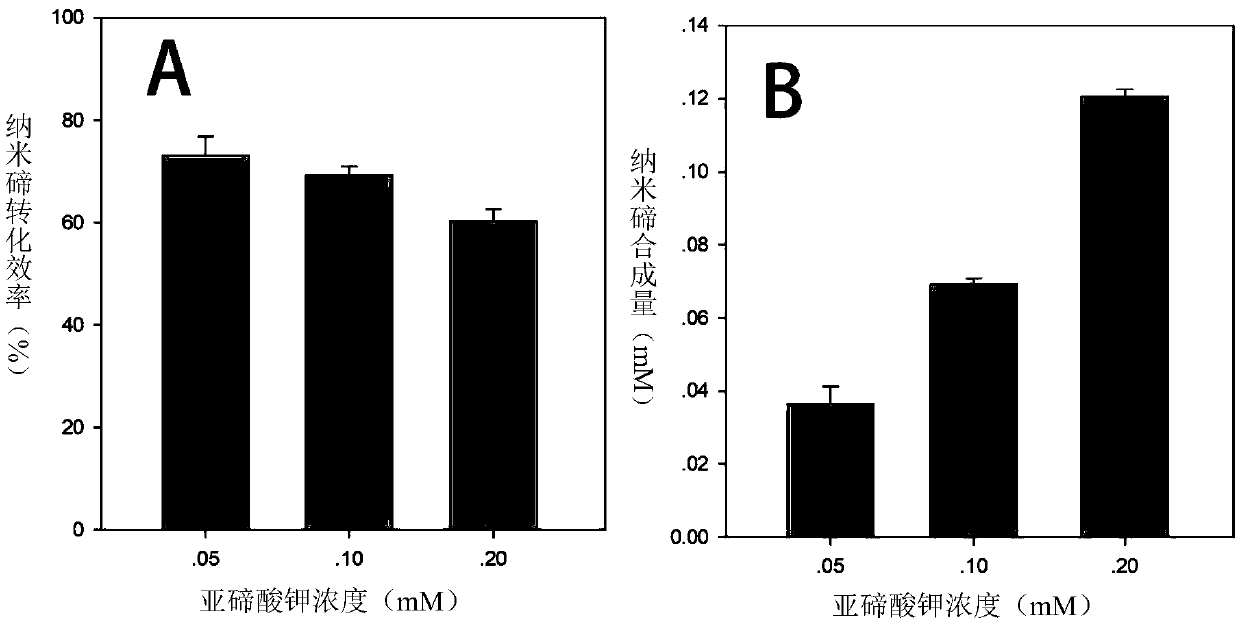

[0054] Example 2 The synthetic efficiency of Bacillus licheniformis S13 to biological nanometer tellurium under different tellurite concentrations

[0055] 1. Preparation of tellurite-containing liquid LB culture medium with different concentrations: prepare the mother liquor of acidite (0.2mM), filter and sterilize; add tellurite solution to the medium, so that the content of tellurite in the medium is 0.05mM, 0.1mM, 0.2mM, three repetitions of each concentration gradient, autoclaved at 121°C for 20min.

[0056] 2. Strain activation: pick a single colony of the S13 strain and inoculate it in LB liquid medium for 12 hours (150rpm, 37°C), then take the above bacterial solution and dilute to OD 600 =0.8; the diluted bacterial solution was inoculated in the above-mentioned tellurium-containing LB medium according to the inoculum amount of 0.1v / v%, and shaken for 72h (150-180rpm, 37°C).

[0057] 3. Determination of tellurite content: fully suspend the S13 bacterial liquid after 4...

Embodiment 3

[0061] The optimal culture time of embodiment 3 bacillus licheniformis S13 synthetic nano-tellurium

[0062] 1. Culture medium preparation and strain activation Refer to steps 1 and 2 in Example 1.

[0063] 2. Adjust the concentration of the activated S13 strain to OD 600 =0.8; the diluted bacterial solution was inoculated in 0.2mM tellurite-containing LB medium according to the inoculum amount of 0.1v / v%, shaken at 37°C and 150rpm, and the control and treatment were replicated 3 times. Samples were taken at 8h, 16h, 24h, 32h, 40h, 48h, 72h, 96h, 120h, and 144h of shaking culture, and each treatment was repeated three times.

[0064] 3. Centrifuge the cultured bacterial solution at 10000rprn for 10min, take 1mL of the supernatant, add 3mL of 0.5M Tris-HCl (pH7.0) solution and 1mL of 10mM DDTC solution, mix well, and measure the absorbance at a wavelength of 340nm within 5min.

[0065] 4. According to the standard curve conversion of tellurite absorbance, the content of tellu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com