A kind of refining method of synthetic ester lubricating oil crude product

A refining method and lubricating oil technology, applied in hydrocarbon oil treatment products, only multi-stage series refining process treatment, hydrocarbon oil treatment, etc., can solve the problems of inability to meet the quality requirements of synthetic ester lubricating oil, lower electrical insulation performance of ester, Solve problems such as high metal ion content, achieve short heating time, low operating pressure and temperature, and good color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

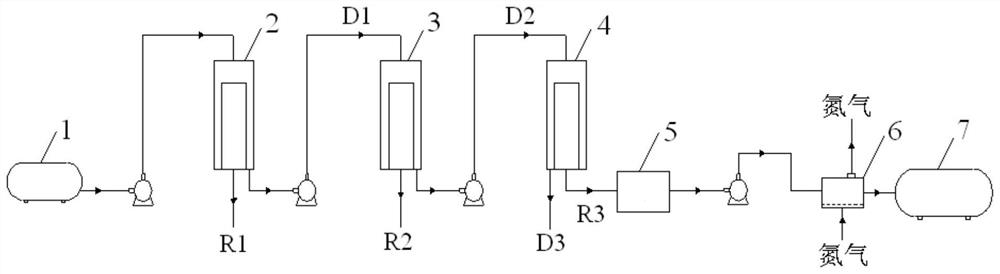

[0037] In this example, the esterification product generated by the esterification reaction of pentaerythritol and isooctanoic acid in the presence of a catalyst is used as the raw material for the crude product of synthetic ester lubricating oil, and its acid value is 12.01 mgKOH / g, which is stored in the crude ester storage tank 1; crude ester refining method process such as figure 1 As shown, the refining steps are as follows:

[0038] 1. First molecular distillation

[0039] The synthetic ester lubricating oil crude product in the crude ester storage tank 1 is pumped into the first-stage molecular distillation equipment 2 for the first molecular distillation, wherein the distillation temperature of the first molecular distillation is controlled to be 170°C, and the condensation temperature is 30°C. The pressure is 7.4 Pa, thereby removing most of the isooctanoic acid and the catalyst (ie R1) in the raw material of the crude synthetic ester lubricating oil, and obtaining t...

Embodiment 2

[0050] In this example, the esterification product generated by the esterification reaction of pentaerythritol and isooctanoic acid in the presence of a catalyst is used as the raw material for the crude product of synthetic ester lubricating oil, and its acid value is 12.01 mgKOH / g, which is stored in the crude ester storage tank 1; crude ester refining method process such as figure 1 As shown, the refining steps are as follows:

[0051] 1. First molecular distillation

[0052] Pump the crude synthetic ester lubricating oil in the crude ester storage tank 1 into the first-stage molecular distillation equipment 2 for the first molecular distillation, wherein the distillation temperature of the first molecular distillation is controlled to be 175°C, and the condensation temperature is 30°C. The pressure is 7.4 Pa, thereby removing most of the isooctanoic acid and the catalyst (ie R1) in the raw material of the crude synthetic ester lubricating oil, and obtaining the deacidifie...

Embodiment 3

[0063] In this example, the esterification product generated by the esterification reaction of pentaerythritol and isooctanoic acid in the presence of a catalyst is used as the raw material for the crude product of synthetic ester lubricating oil, and its acid value is 12.01 mgKOH / g, which is stored in the crude ester storage tank 1; crude ester refining method process such as figure 1 As shown, the refining steps are as follows:

[0064] 1. First molecular distillation

[0065] The crude synthetic ester lubricating oil in the crude ester storage tank 1 is added to the first-stage molecular distillation equipment 2 to carry out the first molecular distillation, wherein the distillation temperature of the first molecular distillation is controlled to be 180°C, and the condensation temperature is 30°C. The pressure is 10 Pa, thereby removing most of the isooctanoic acid and the catalyst (ie R1) in the raw material of the crude synthetic ester lubricating oil, and obtaining the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative humidity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com