Method for producing high maltose syrup by utilizing mpeg-mal5000-β-amylase

A technology of high maltose syrup and amylase, applied in the direction of fermentation, etc., can solve the problems such as β-amylase rarely reported, and achieve the effect of shortening the enzymatic hydrolysis time, lowering the enzymatic hydrolysis temperature, and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

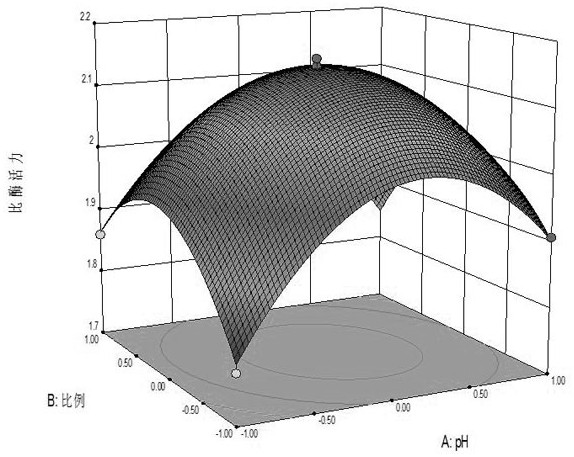

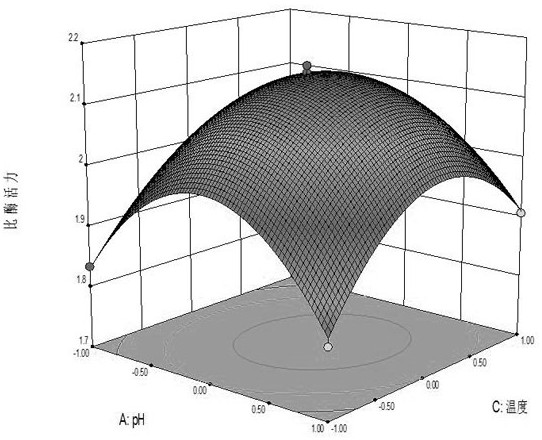

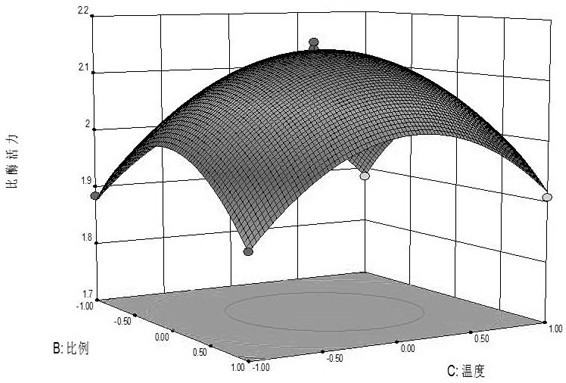

Image

Examples

Embodiment Construction

[0024] 1. Preparation of mPEG-Mal5000-β-amylase

[0025] 1 Materials and methods

[0026] 1.1 Materials and Instruments

[0027] 1.1.1 Reagents

[0028] β-amylase: American Sigma-Aldrich Company, molecular weight 55.7kDa, specific enzyme activity 17,000 U / mg; mPEG-NHS5000, mPEG-NHS20000, mPEG-Ts5000, mPEG-Ts10000, mPEG-Ts20000 and mPEG-Mal5000, Nanocs, USA company, purity ≥95%. All other reagents were of domestic analytical grade.

[0029] 1.1.2 Instruments and equipment

[0030] UV-Vis spectrophotometer: WFJ7200 (Unocal Shanghai Instrument Co., Ltd.);

[0031] Constant temperature water bath: DZKW-4 (Beijing Zhongxing Weiye Instrument Co., Ltd.);

[0032] Oscillating constant temperature metal bath: TUS-200P (Shanghai Yiheng Technology Co., Ltd.).

[0033] 1.2.2 mPEG modified β-amylase reaction

[0034] Add 8.0 mL of disodium hydrogen phosphate-citrate buffer solution of a certain pH to the test tube, then add 1.0 mL of 125 μmol / L β-amylase enzyme solution and 1.0 mL ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com