Cathode interface modification method for improving performance of organic electroluminescent device and preparation method of organic electroluminescent device

A technology of cathode interface and modification method, which is applied in the fields of electrical solid device, semiconductor/solid state device manufacturing, electrical components, etc., can solve the high requirements of device processing environment and encapsulation technology, cannot use stable high work function metal, and increase the process process. Difficulty and other problems, to achieve the effect of improving the performance of organic electroluminescent devices, increasing the electron current density, and improving the performance of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

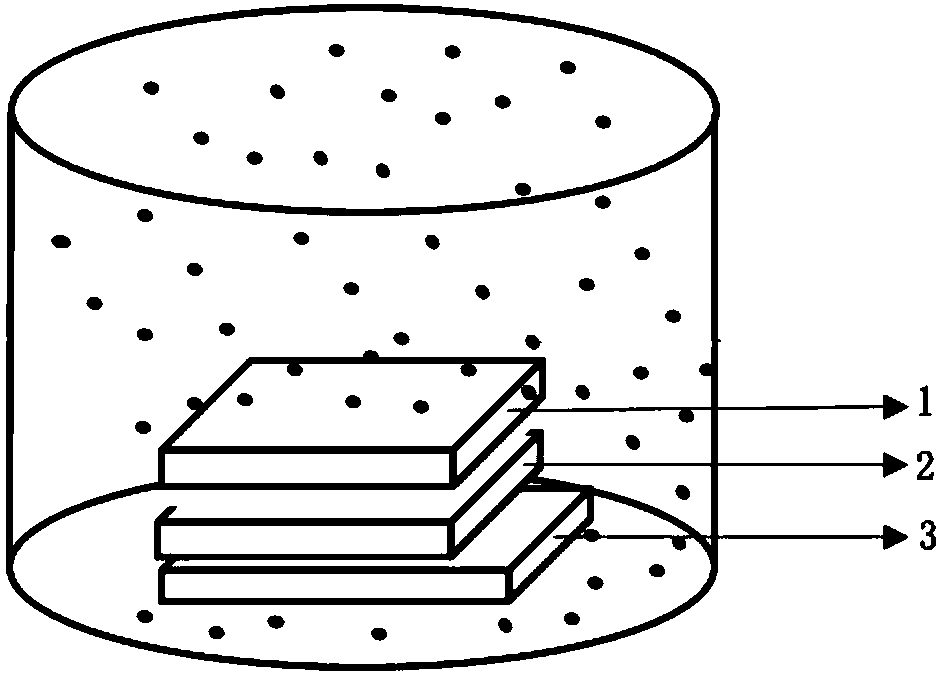

[0037] The preparation process of the organic electroluminescent device of this embodiment is as follows:

[0038] (1) Cleaning and drying of ITO substrate

[0039] ITO glass square resistance ~ 20Ω / □, size 15mm×15mm square piece. The following steps are used to clean ITO glass: acetone → isopropanol → special detergent for micron semiconductors (a mixed solution of ZT-3 electronic washing liquid and deionized water with a volume ratio of 1:100) → twice deionized water → new Ultrasonic cleaning with isopropanol for 10 minutes each, and drying in a constant temperature oven for two hours for later use. Before use, the ITO clean sheet needs to be processed in the O2plasma system (processing condition parameters: 190V; 120mA; 100Pa; 20min), the purpose is to remove residual organic stains, improve interface contact angle, and improve work function.

[0040] (2) Preparation of hole injection layer

[0041] After the treatment of the ITO glass substrate is completed, spin-coat P...

Embodiment 2

[0057] The cathode interface modification method for improving the performance of organic electroluminescent devices in this embodiment has the same other features as in Embodiment 1, except that in this case, the solution steam treatment time in step C is 30 minutes.

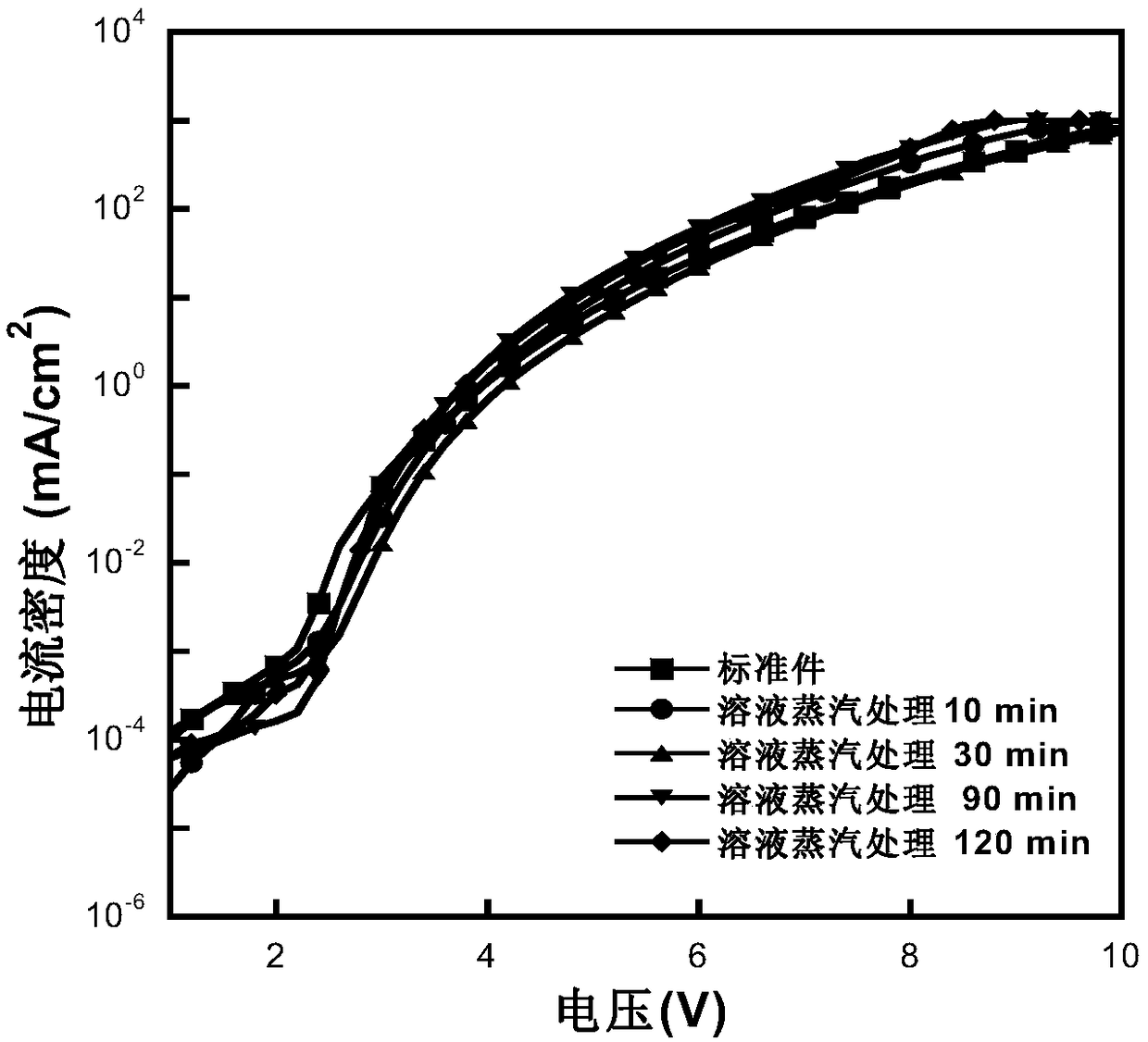

[0058] The current density-voltage curve of the organic light-emitting device of this embodiment is as follows figure 2 As shown (PSVA 30min in the figure), compared with the current density-voltage curve (PSVA in the figure) of the organic light-emitting device whose light-emitting layer has not been treated with solution vapor, the standard part achieves 1000cd / m 2 Under the required voltage of 5.6V and current density of 31.6 mA / cm 2 ,After 10 minutes of solution steam treatment, 1000cd / m 2 Only need a smaller voltage of 5.6V and a smaller current density of 21.7mA / cm 2 .

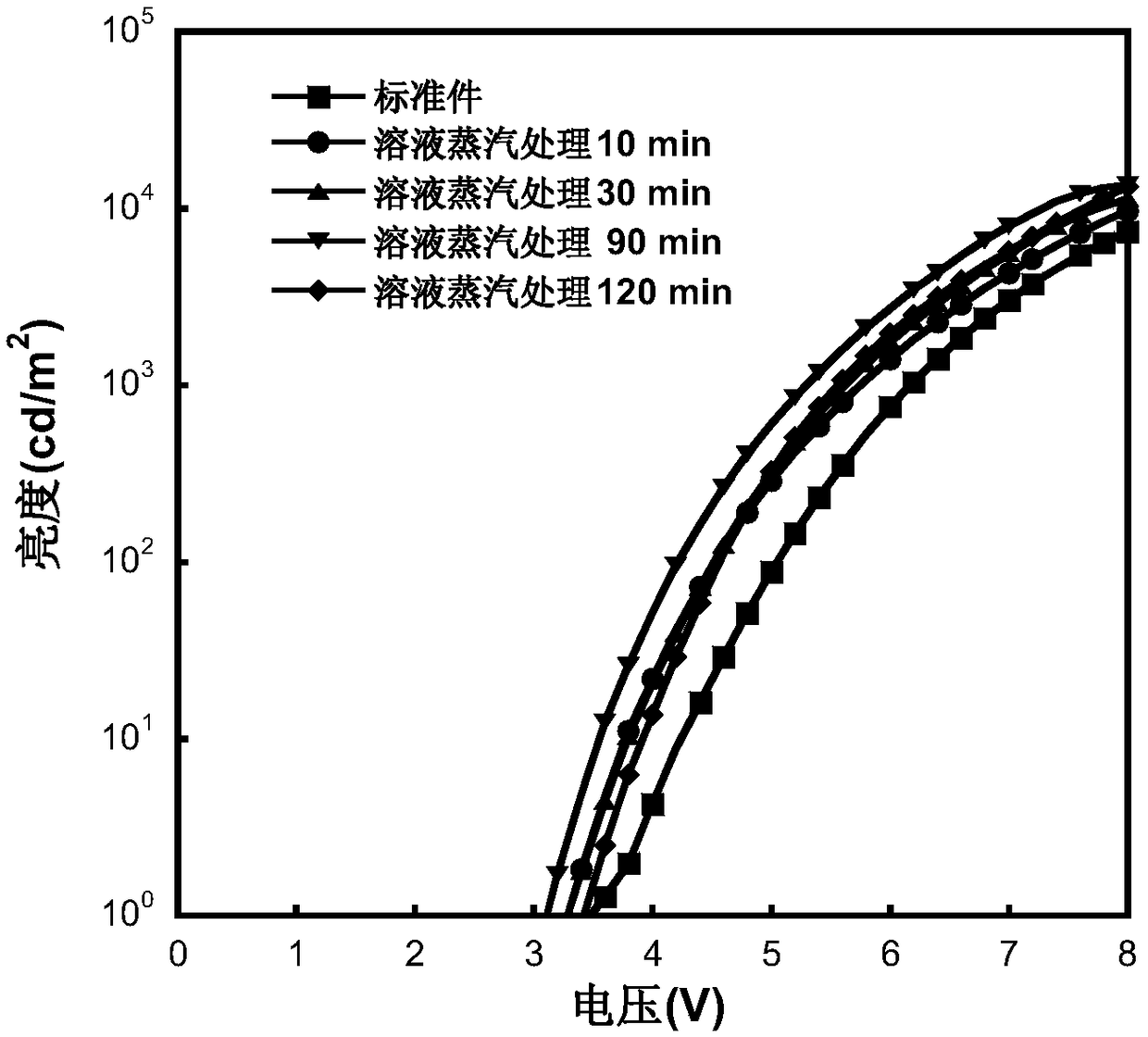

[0059] The voltage-brightness curve of the organic light-emitting device of this embodiment is as follows image 3 As shown (PSVA 3...

Embodiment 3

[0064] The cathode interface modification method for improving the performance of organic electroluminescent devices in this embodiment has the same other features as Case 1, except that the solution steam treatment time in step C in this case is 90 minutes and 120 minutes.

[0065] The current density-voltage curve of the organic light-emitting device of this embodiment is as follows figure 2 As shown (PSVA90min in the figure), compared with the current density-voltage curve (PSVA in the figure) of the organic light-emitting device whose light-emitting layer has not been treated with solution vapor, the standard component achieves 1000cd / m 2 Under the required voltage of 5.6V and current density of 31.6mA / cm 2 ,After 10 minutes of solution steam treatment, 1000cd / m 2 Only need a smaller voltage of 5.0V and a smaller current density of 17.9mA / cm 2 .

[0066] The voltage-brightness curve of the organic light-emitting device of this embodiment is as follows image 3 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com