A dual direct current motor forward series control system and method

A double DC motor, series control technology, applied in the direction of DC motor rotation control, DC motor speed/torque control, control system, etc., can solve problems that are not suitable for solving, inapplicable, and difficult to calculate, and achieve a wide range of applications and improve Stability, achieve simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

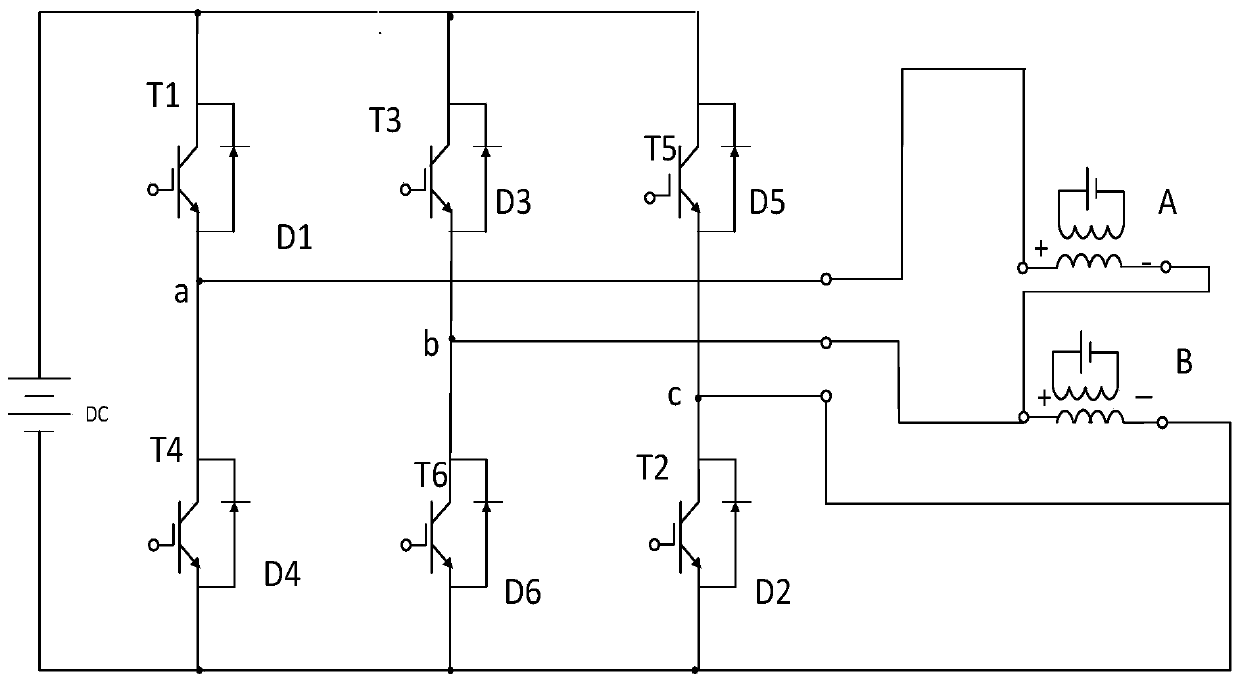

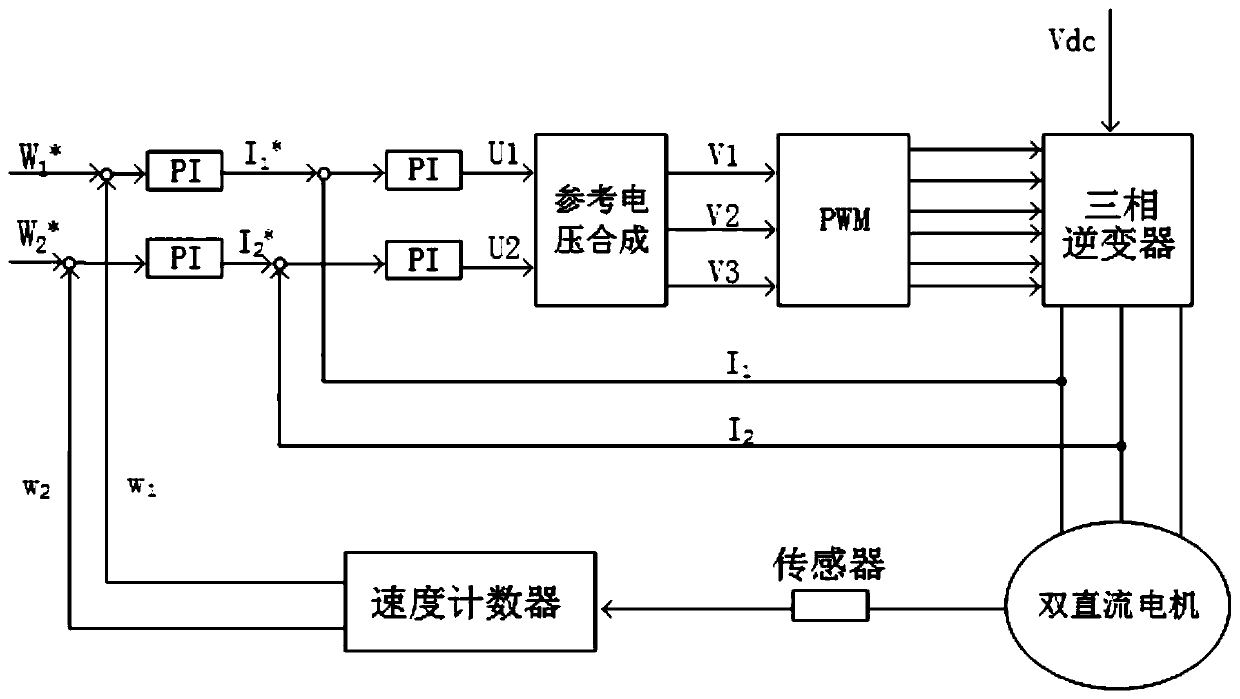

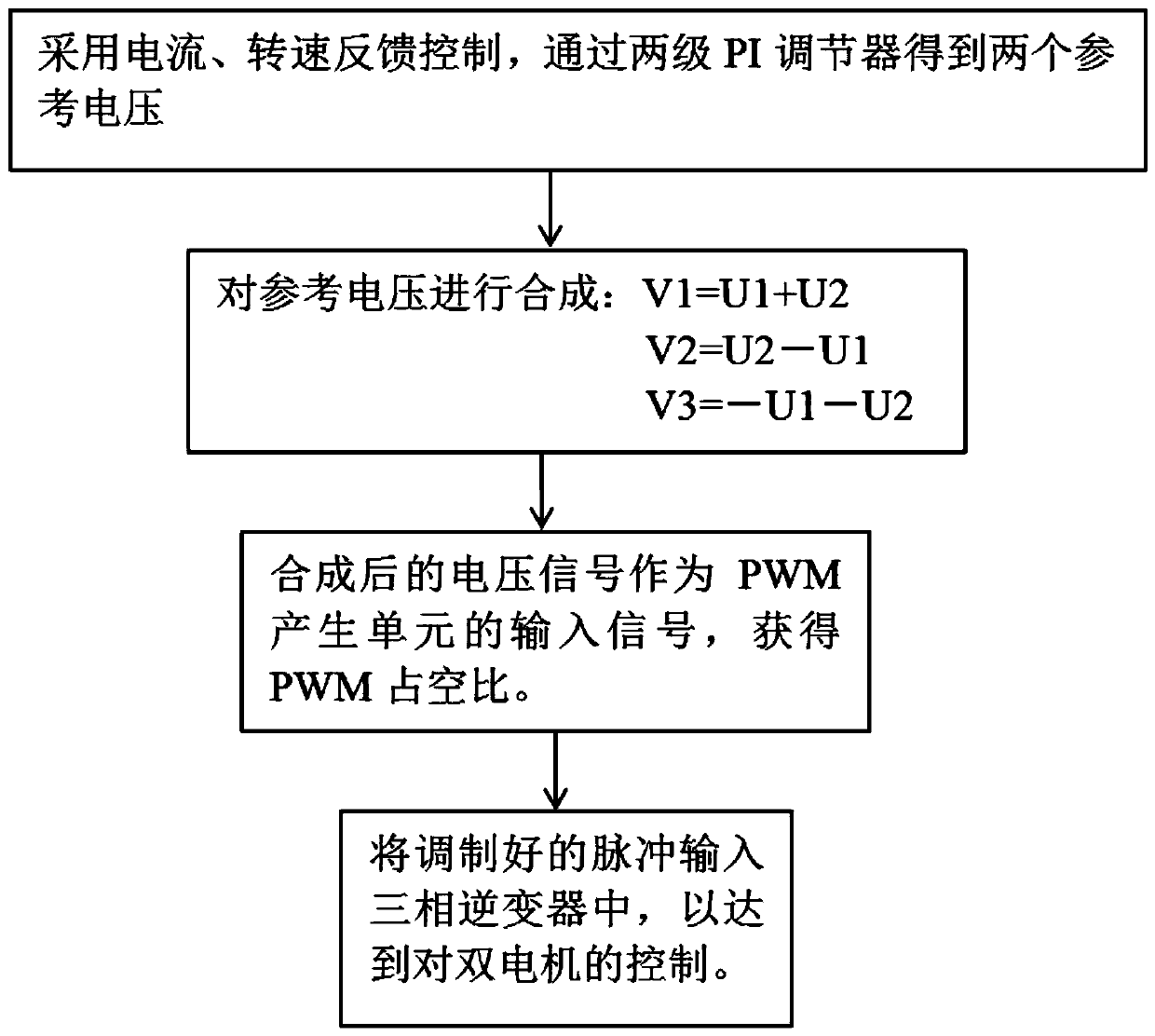

[0040] The invention provides a forward series control system of double DC motors. The forward series control system of double DC motors uses six IGBT modules to form three bridge arms in parallel connection at both ends of the DC power supply. The double DC motors are connected in series in the forward direction, the positive pole of the first motor is connected to the negative pole of the second motor, and the first bridge arm is composed of bipolar transistor chips T1, T4 and diode chips D1, D4 connected in parallel on them. The second bridge arm is composed of bipolar transistor chips T3, T6 and diode chips D3, D6 connected in parallel thereon, and the third bridge arm is composed of bipolar transistor chips T5, T2 and diode chips D5, D2 connected in parallel thereon composition. The coupled inductance elements A and B on the double DC motor are respectively connected in series in the three bridge arms, and the energy is transmitted to the motor drive circuit. The level P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com