Preparation method of whole navel orange fruit juice

A navel orange and fruit juice technology, which is applied in the field of preparation of navel orange whole fruit juice, can solve the problems of strong bitterness, poor taste, easy color change of the juice, etc., and achieve the effect of excellent color, fragrance and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

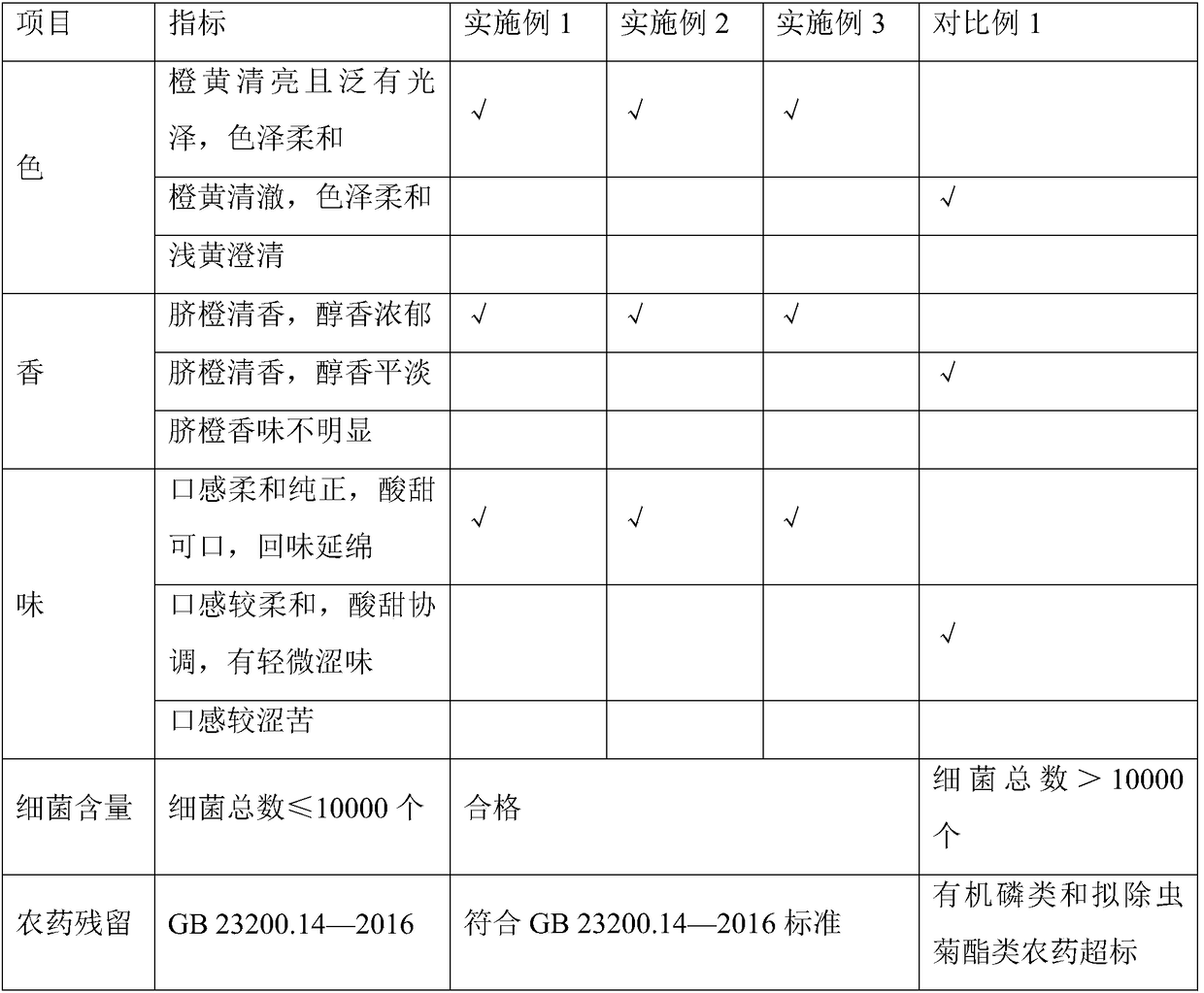

Examples

Embodiment 1

[0022] A preparation method of navel orange whole fruit juice of the present invention, comprises the following steps:

[0023] (1) Fresh navel oranges are washed and put into an ozone pool provided with a plurality of high-voltage pulse discharge electrodes, and the navel orange peel is sterilized and residual pesticides are degraded by using ozone oxidation in conjunction with high-voltage pulse discharge; wherein, the concentration of ozone in the ozone pool The high-voltage pulse discharge electrode is set at the bottom of the ozone pool. The positive electrode is a tungsten wire and the negative electrode is a stainless steel plate. The discharge electrode is connected to a high-voltage pulse power supply. The distance between the tungsten wire positive electrode and the stainless steel negative electrode is 25mm. The frequency is 50Hz, the pulse width is 8μs, and the time of ozone oxidation and high voltage pulse discharge is 60min.

[0024] (2) Grinding the navel orange...

Embodiment 2

[0028] A preparation method of navel orange whole fruit juice of the present invention, comprises the following steps:

[0029] (1) Fresh navel oranges are washed and put into an ozone pool provided with a plurality of high-voltage pulse discharge electrodes, and the navel orange peel is sterilized and residual pesticides are degraded by using ozone oxidation in conjunction with high-voltage pulse discharge; wherein, the concentration of ozone in the ozone pool The high-voltage pulse discharge electrode is set at the bottom of the ozone pool. The positive electrode is a tungsten wire and the negative electrode is a stainless steel plate. The discharge electrode is connected to a high-voltage pulse power supply. The distance between the tungsten wire positive electrode and the stainless steel negative electrode is 25mm. The frequency is 50Hz, the pulse width is 8μs, and the time of ozone oxidation and high-voltage pulse discharge is 50min.

[0030] (2) Grinding the navel orange...

Embodiment 3

[0034] A preparation method of navel orange whole fruit juice of the present invention, comprises the following steps:

[0035] (1) Fresh navel oranges are washed and put into an ozone pool provided with a plurality of high-voltage pulse discharge electrodes, and the navel orange peel is sterilized and residual pesticides are degraded by using ozone oxidation in conjunction with high-voltage pulse discharge; wherein, the concentration of ozone in the ozone pool The high-voltage pulse discharge electrode is set at the bottom of the ozone pool. The positive electrode is a tungsten wire and the negative electrode is a stainless steel plate. The discharge electrode is connected to a high-voltage pulse power supply. The distance between the tungsten wire positive electrode and the stainless steel negative electrode is 25mm. The frequency is 50Hz, the pulse width is 8μs, and the time of ozone oxidation and high voltage pulse discharge is 60min.

[0036] (2) Grinding the navel orange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com