Amidoxime-based magnetic polyphosphazene nano-microspheres with core-shell structure and preparation thereof as well as application of amidoxime-based magnetic polyphosphazene nano-microspheres serving as uranium adsorbent

A technology of nano-microspheres and polyphosphazene, which is applied in nuclear engineering, radioactive purification, and other chemical processes, can solve the problems of low utilization rate and complicated synthesis methods, and achieve enhanced hydrophilicity, large adsorption capacity, and good The effect of surface adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

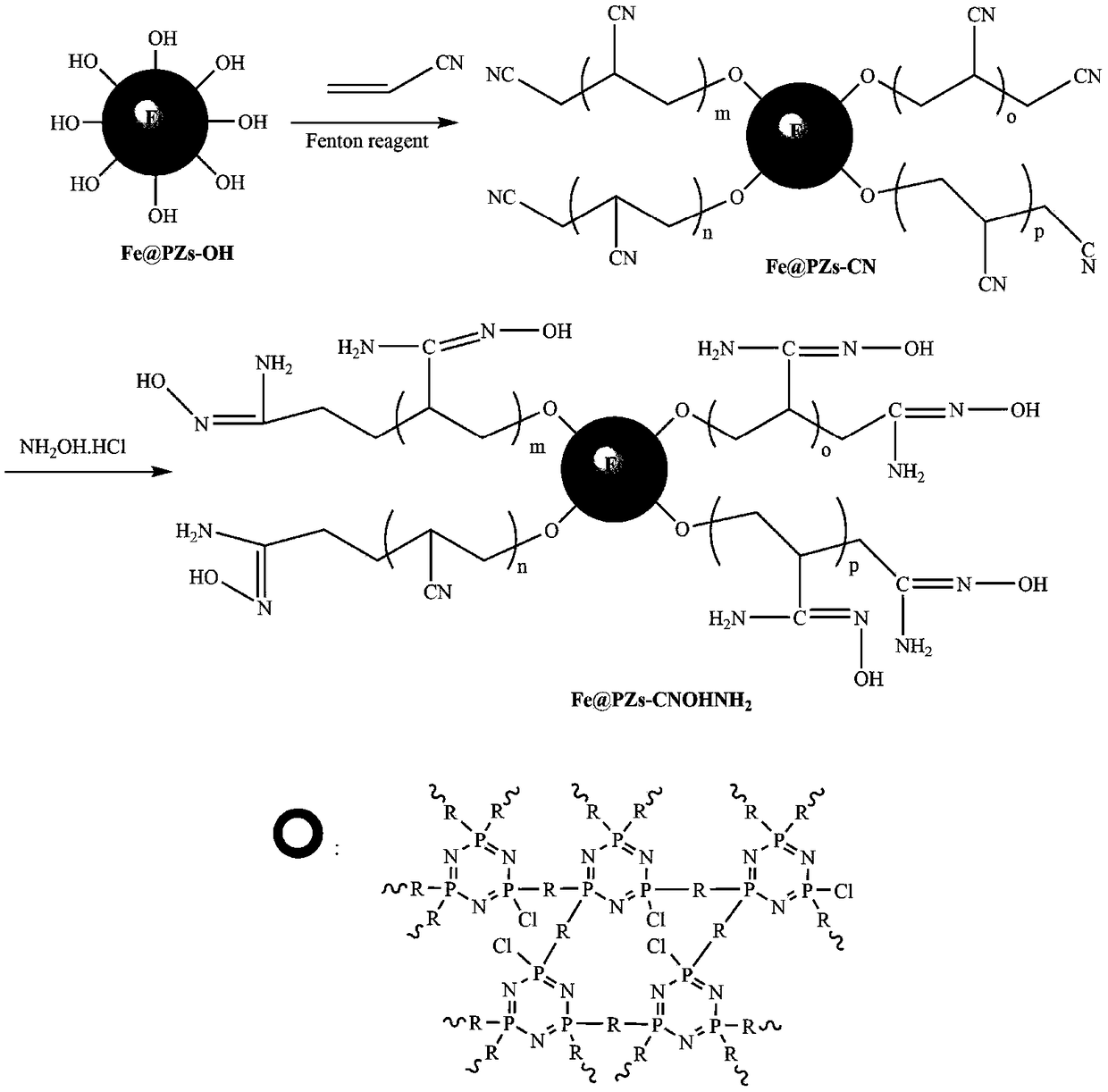

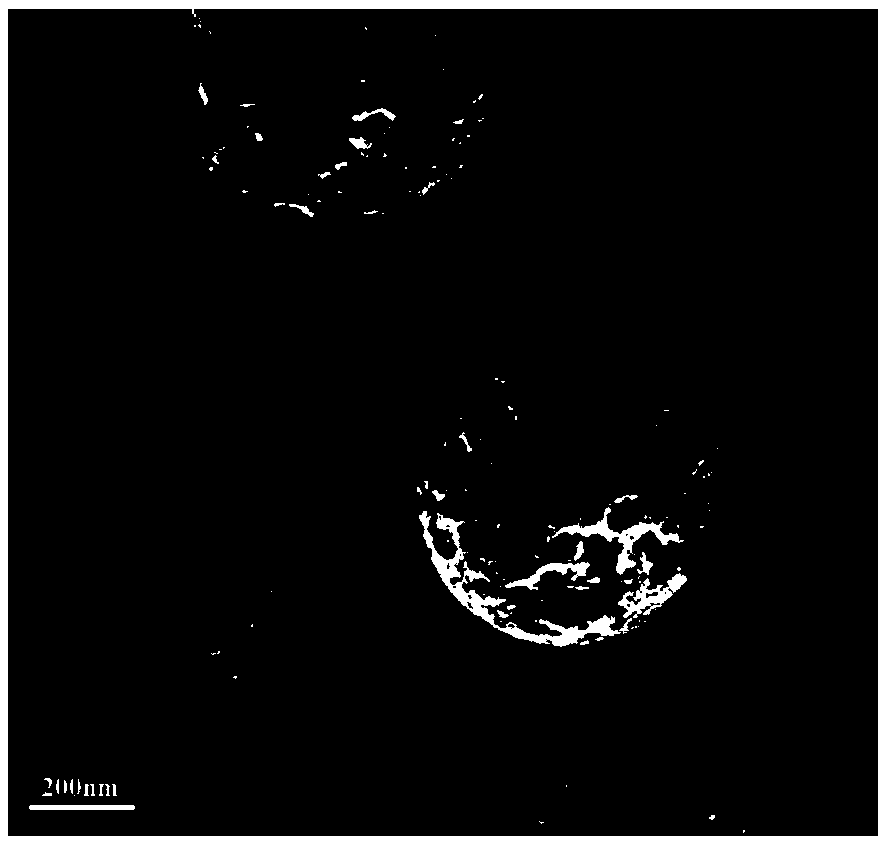

[0045] After ultrasonically dispersing the prepared magnetic particles in acetonitrile for 10 min, 3.476 g of hexachlorocyclotriphosphazene HCCP, 7.51 g of 4,4'-dihydroxydiphenyl sulfone BPS and 9.09 g of triethylamine were added to the solution, at 40 Ultrasonic water bath at ℃ for 2 hours (150 watts, 80kHZ), centrifuged, washed with ethanol, and dried in vacuum to obtain active hydroxyl polyphosphazene microspheres;

[0046] Add 0.5g of active hydroxyl polyphosphazene nanospheres and 1g of ferrous sulfate heptahydrate to 50mL of deionized water, and after ultrasonic vibration at 30°C for 5min, add 2g of acrylonitrile and 2g of 30% peroxygen water, and stir at 25°C for 5h , to obtain polyphosphazene nanospheres containing active cyano groups;

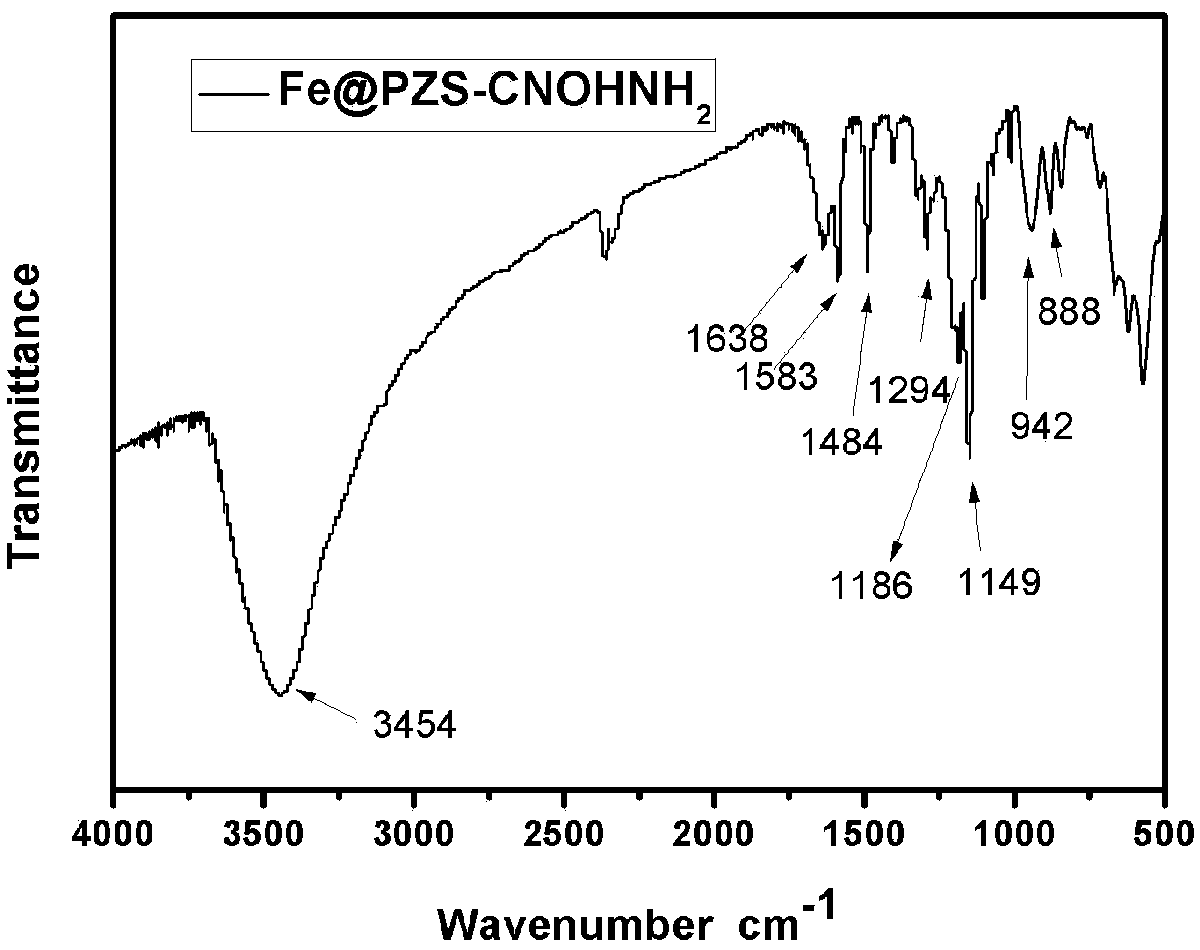

[0047] 1 g of activated cyanopolyphosphazene nanospheres and 5 g of NH 2 Add OH·HCl to 100 g of deionized water, adjust the pH to 8.0, stir at 80°C for 4 hours, and separate the final product with a magnet to obtain the amidoxime-base...

Embodiment 2

[0052] After the prepared magnetic particles were ultrasonically dispersed in acetonitrile for 10 min, 3.476 g of hexachlorocyclotriphosphazene HCCP, 4.41 g of hydroquinone and 9.09 g of triethylamine were added to the solution, and ultrasonic water bath was carried out at 40°C for 2 h (150 Watts, 80kHZ), after centrifugation, wash with ethanol and vacuum-dry to obtain active hydroxyl polyphosphazene microspheres;

[0053] Add 0.5g of polyphosphazene nanospheres containing active hydroxyl groups and 1g of ferrous sulfate heptahydrate to 30mL of deionized water. After ultrasonic vibration at 30°C for 20min, add 1g of acrylonitrile and 1g of 30% peroxygen water, and stir at 35°C for 3h Finally, polyphosphazene nanospheres containing active cyano groups are obtained;

[0054] 1 g of activated cyanopolyphosphazene nanospheres and 5 g of NH 2 Add OH·HCl to 100 g of deionized water, adjust the pH to 8.0, stir at 80°C for 4 hours, and separate the final product with a magnet to obta...

Embodiment 3

[0056] After ultrasonically dispersing the prepared magnetic particles in acetonitrile for 10 min, add 3.476 g of hexachlorocyclotriphosphazene HCCP, 6.84 g of bisphenol A and 9.09 g of triethylamine into the solution, and ultrasonically disperse them in a water bath at 40°C for 2 h (150 watts , 80kHZ), after centrifugation, wash with ethanol and vacuum-dry to obtain active hydroxyl polyphosphazene microspheres;

[0057] Add 1g of active hydroxyl polyphosphazene nanospheres and 2g of ferrous sulfate heptahydrate to 50mL of deionized water, and after ultrasonic vibration at 40°C for 10min, add 2g of acrylonitrile and 2g of 30% peroxygen water, and stir at 35°C for 3h, Obtaining polyphosphazene nanospheres containing active cyano groups;

[0058] 1 g of activated cyanopolyphosphazene nanospheres and 5 g of NH 2 Add OH·HCl to 100 g of deionized water, adjust the pH to 8.0, stir at 80°C for 4 h, and separate the final product with a magnet to obtain the magnetic polyphosphazene n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com