Preparing method of ACF (activated carbon fiber) catalyst loaded with transition metal oxide and capable of degrading VOCs (volatile organic compounds) at room temperature

A transition metal and transition metal salt technology, applied in the field of environmental governance, can solve the problems of high resistance of foamed nickel and unfavorable industrial application, and achieve the effects of low cost, easy exhaust gas penetration, and strong ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

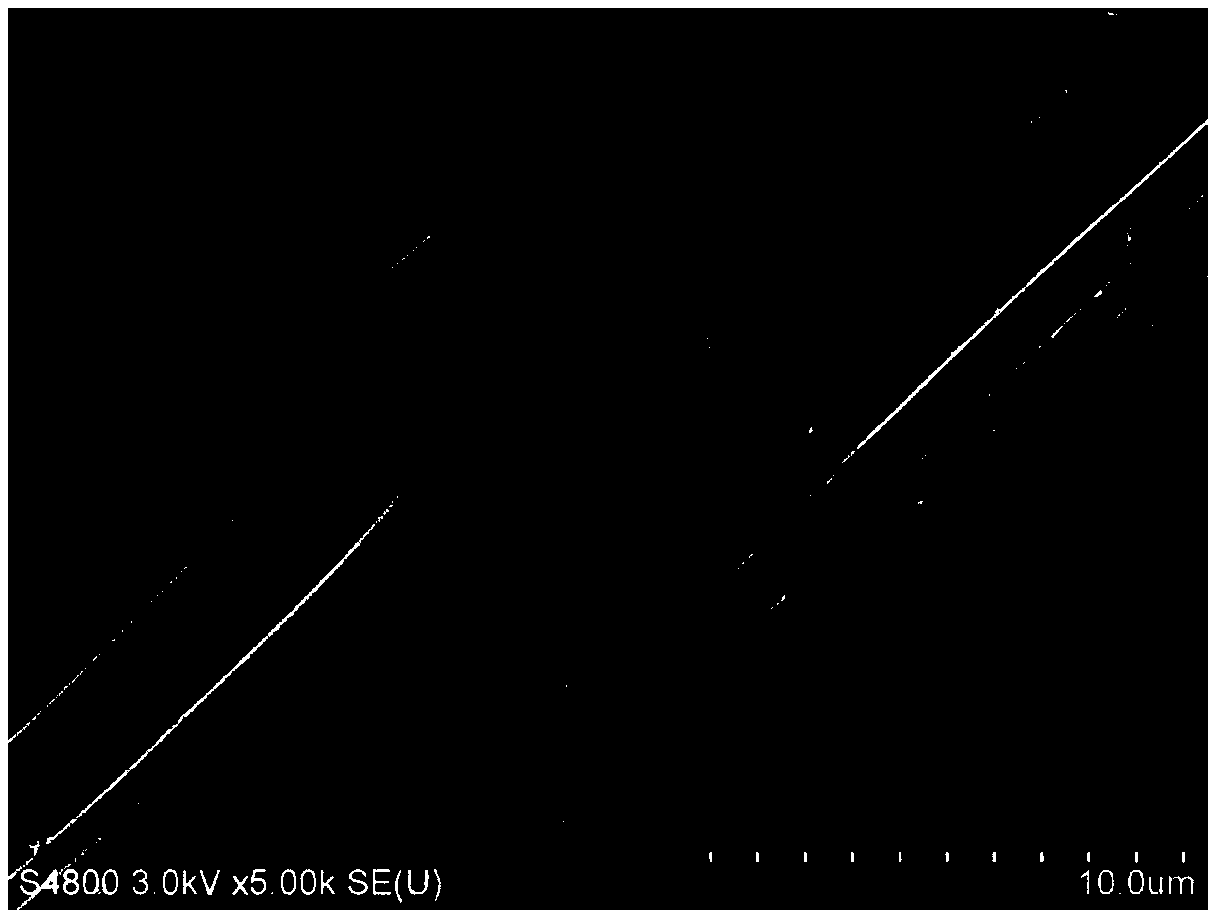

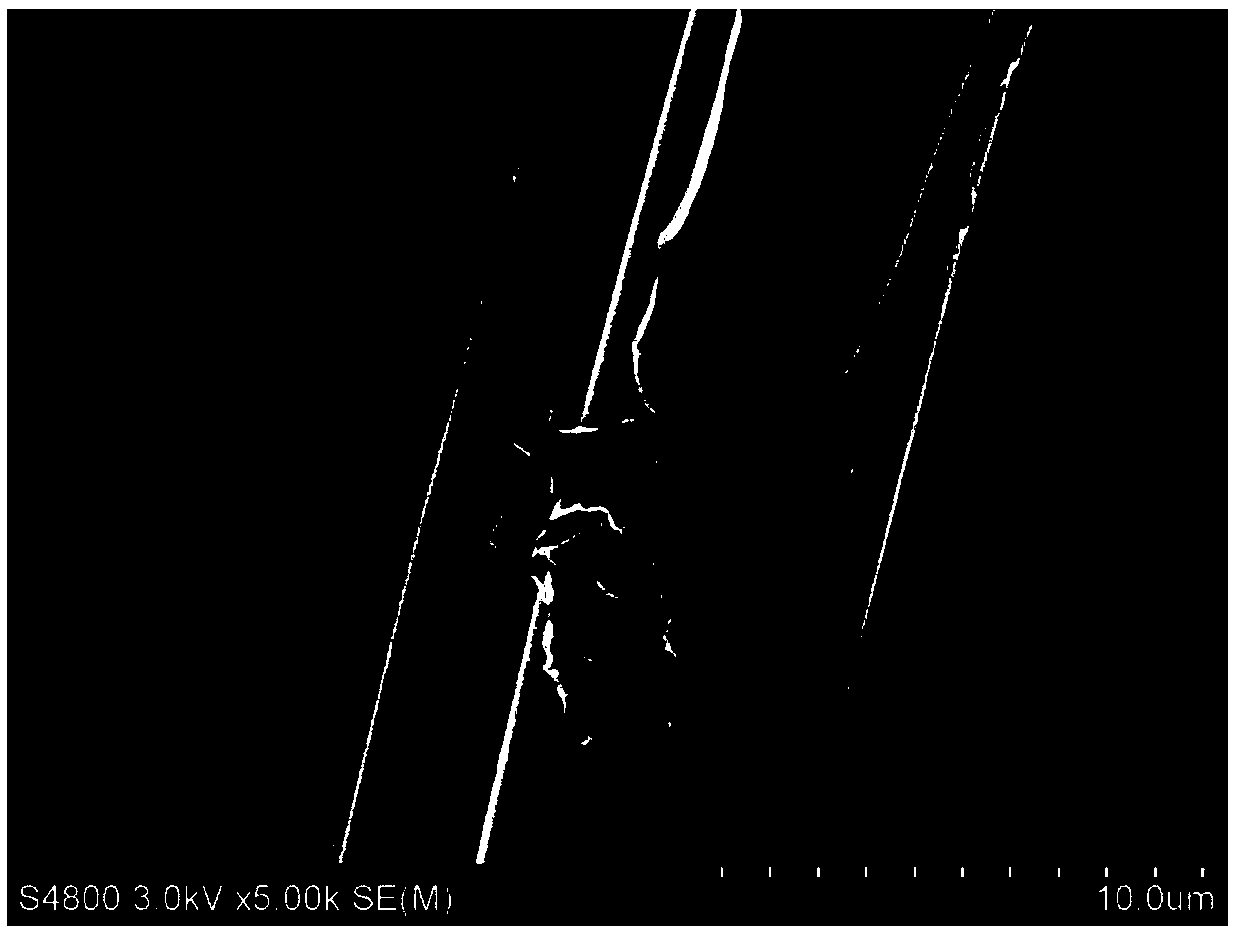

Image

Examples

preparation example Construction

[0021] The preparation method of the ACF catalyst loaded with transition metal oxides for degrading VOCs at normal temperature of the present invention comprises the following steps:

[0022] Step 1, ACF preprocessing:

[0023] Submerge the ACF in 5-30% HNO by volume 3 solution, and put the solution in a 40-100°C water bath for 2-10h. Then take out ACF, and wash to neutrality with distilled water, dry naturally, the specific surface area of described ACF is 1000-3000m 2 / g, the external area is 0.2-2.0m 2 / g.

[0024] Preferred, HNO 3 HNO in solution 3 The volume concentration is 10-15%. The concentration is moderate, which can dissolve most of the soluble impurities on the ACF, and at the same time avoid the damage to the carbon fiber structure caused by excessive concentration.

[0025] Preferably, the temperature range of the water bath is 60-80°C. Preferably, the reaction time is 3-6h. Speed up the reaction rate and avoid the volatilization and decomposition o...

Embodiment 1

[0036] (1) Pretreatment of ACF. Prepare HNO in the concentration range of 5% 3 solution, immerse 1 g of ACF in 5% concentration of HNO 3 solution, and the solution was placed in a 40°C water bath for 10 h. Then take out the ACF, wash with distilled water until neutral, and let it dry naturally. The specific surface area of the ACF is 1000m 2 / g, the outer area is 0.2m 2 / g.

[0037] (2) Impregnating and supporting Cu. Weigh a certain amount of copper nitrate according to the ratio of Cu element mass to ACF mass ratio of 2%, add distilled water to dissolve, add pretreated ACF, and ultrasonically disperse for 0.5 h. Let it stand for 20 hours after the ultrasound. Take it out after standing, and dry it in a 50°C oven.

[0038] (3) Programmed temperature calcination. Put the dried Cu-loaded ACF into a temperature-programmed muffle furnace, raise it to 100°C at 1°C / min, and then keep the temperature for 10h to prepare the loaded CuO with a Cu content of 2%. x ACF cataly...

Embodiment 2

[0041] (1) Pretreatment of ACF. Prepare HNO in the concentration range of 10% 3 solution, immerse 1 g of ACF in 10% concentration of HNO 3 solution, and the solution was placed in a 60°C water bath for 6h. Then take out the ACF, wash with distilled water until neutral, and let it dry naturally. The specific surface area of the ACF is 1600m 2 / g, the external area is 0.7m 2 / g.

[0042] (2) Impregnating loaded Mn. A certain amount of manganese acetate was weighed according to the ratio of Mn element mass to ACF mass ratio of 8%, dissolved in distilled water, added with pretreated ACF, and ultrasonically dispersed for 1 h. Let it stand for 15 hours after the ultrasound. Take it out after standing, and dry it in a 70°C oven.

[0043] (3) Programmed temperature calcination. Put the dried Mn-loaded ACF into a temperature-programmed muffle furnace, raise it to 200°C at 3°C / min, and then keep the temperature for 8h to prepare MnO with a Mn content of 8%. x ACF catalyst.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| External area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com