Water-lubricated bearing comprehensive performance test bench

A water-lubricated bearing and comprehensive performance technology, applied in the direction of mechanical bearing testing, etc., can solve problems such as large floor space, and achieve the effect of reducing floor space, comprehensive testing and verification, and easy disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

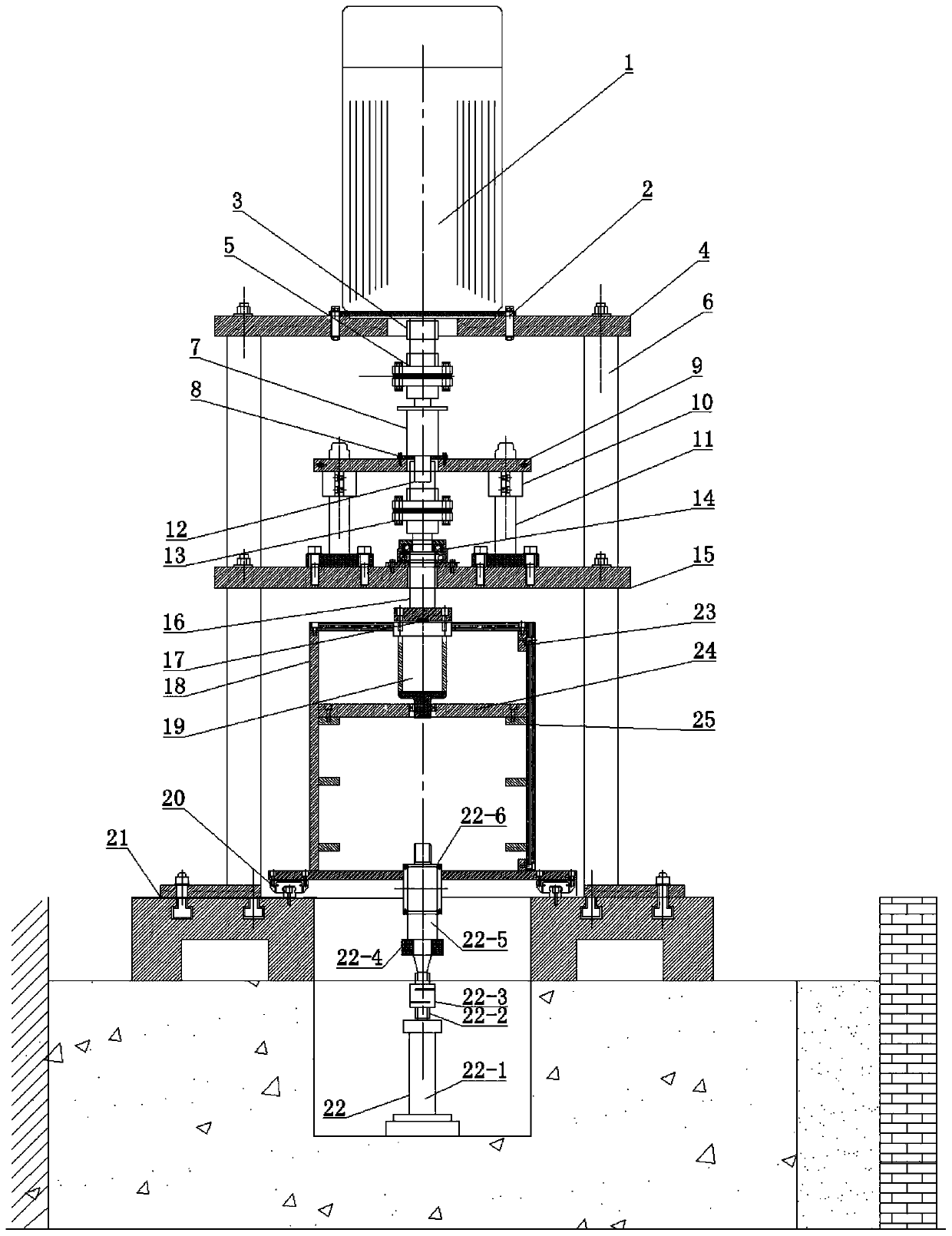

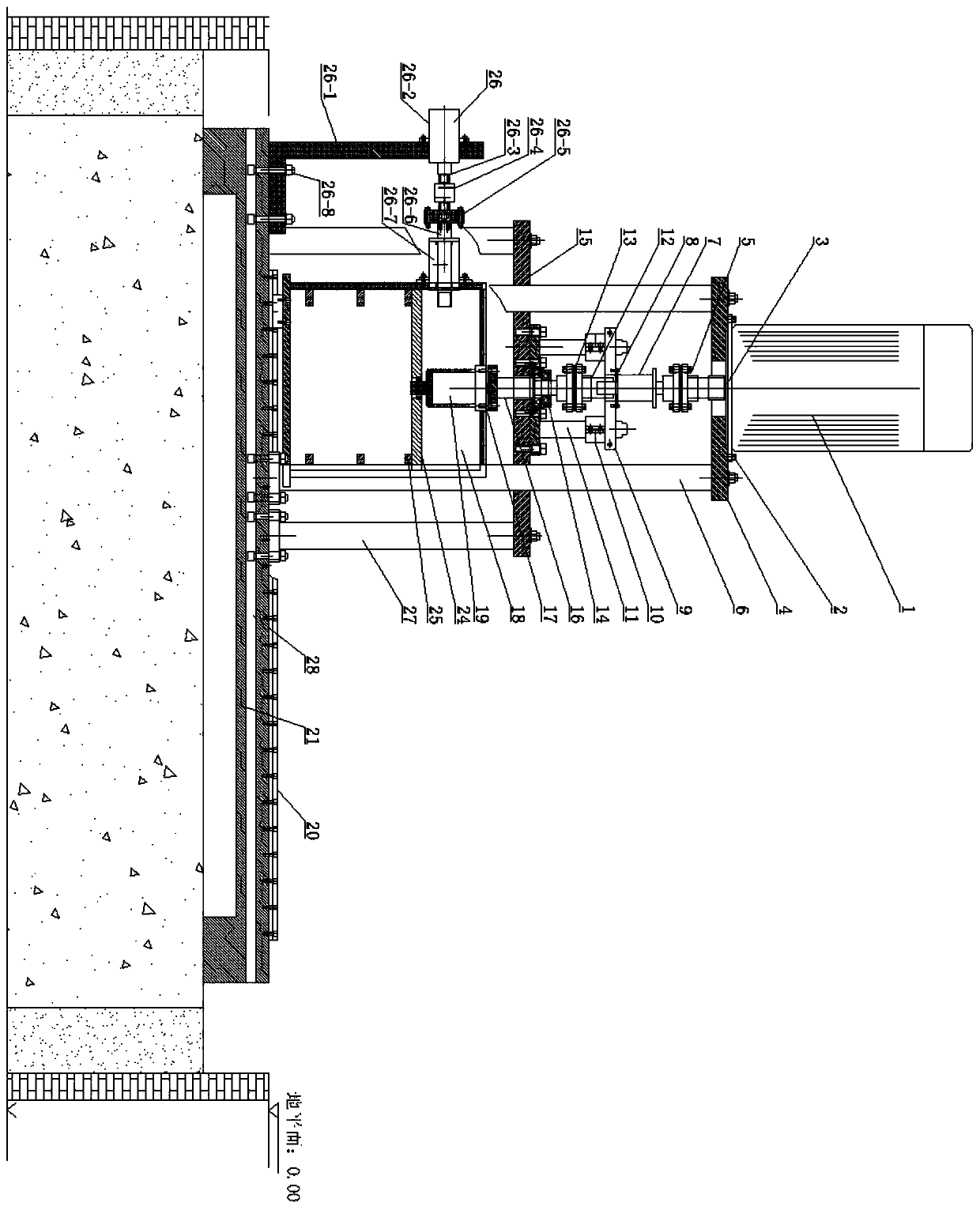

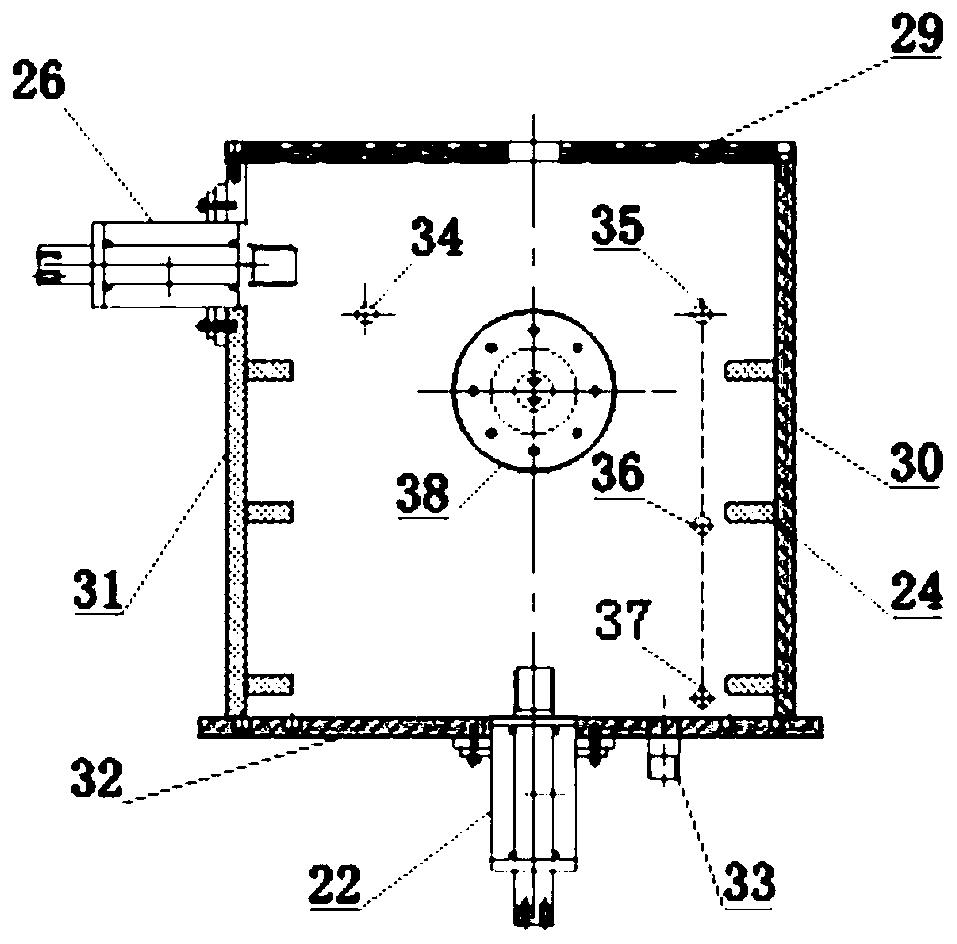

[0032] The water-lubricated bearing comprehensive performance test bench provided by the present invention has a structure such as Figure 1-4 As shown, it includes frequency conversion motor 1, motor platform column 6, torque sensor 7, first column 11, transmission shaft 16, rotating shaft 19, radial and axial hybrid bearing housing 14, experimental cabin 18, axial loading device 22, radial Loading device 26 , guide rail 20 , mounting plate 21 , and second column 27 .

[0033] The variable frequency motor 1 and the torque sensor 7 are connected through the upper coupling 5 of the sensor, and an encoder 3 is set; the upper coupling 5 of the sensor adopts an elastic coupling to adapt to the radial high-frequency beating and other movements caused by the motor running. Various deviations are beneficial to protect the variable frequency motor and torque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com