Colored ceramic coating film coated with aramid polymer, and preparation method thereof

A ceramic coating, polymer technology, applied in the direction of separators/films/diaphragms/spacers, electrical components, circuits, etc., can solve the problems of uneven pores, poor high temperature resistance, negative impact on battery performance, etc. Achieve the effect of improving safety performance, improving cycle performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

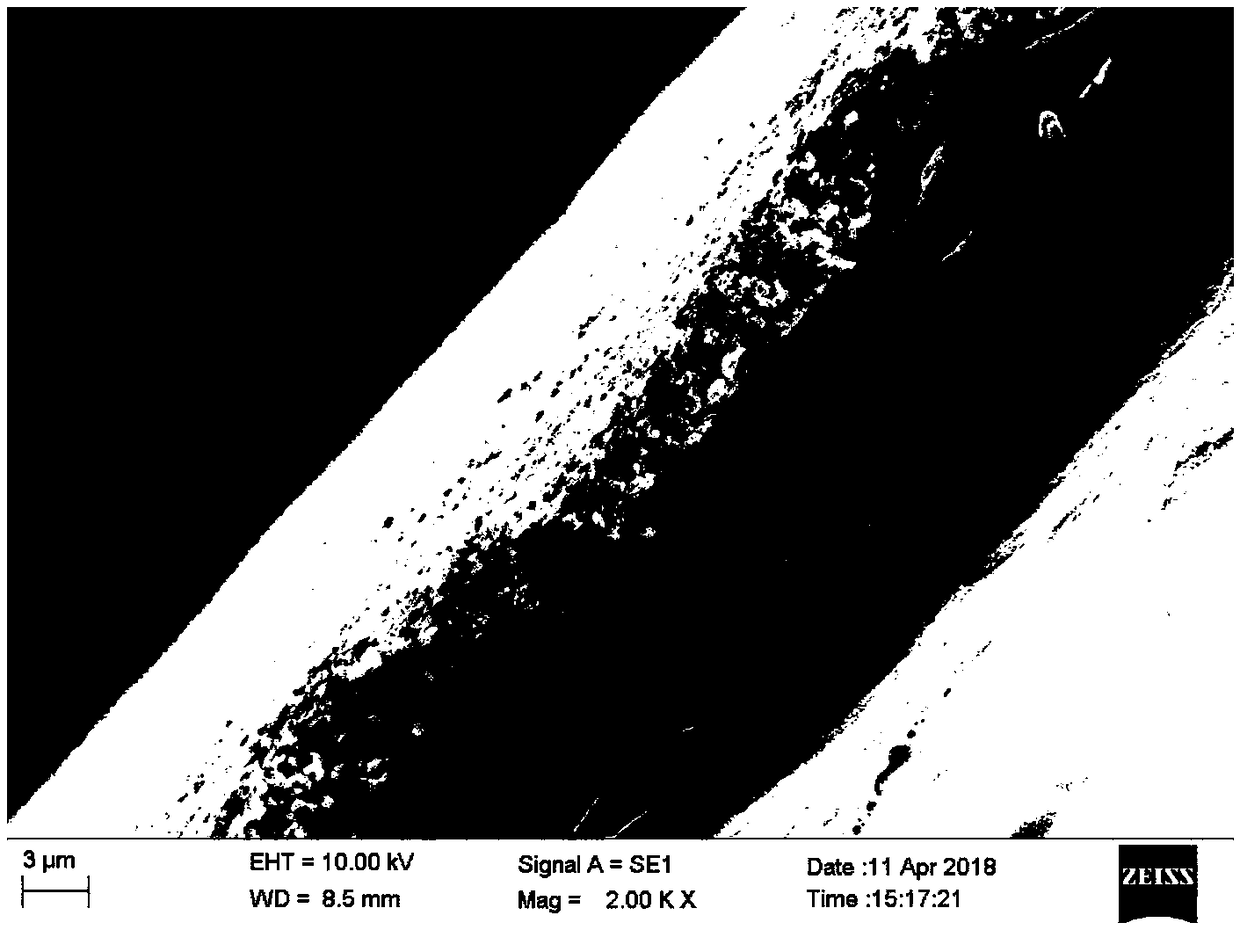

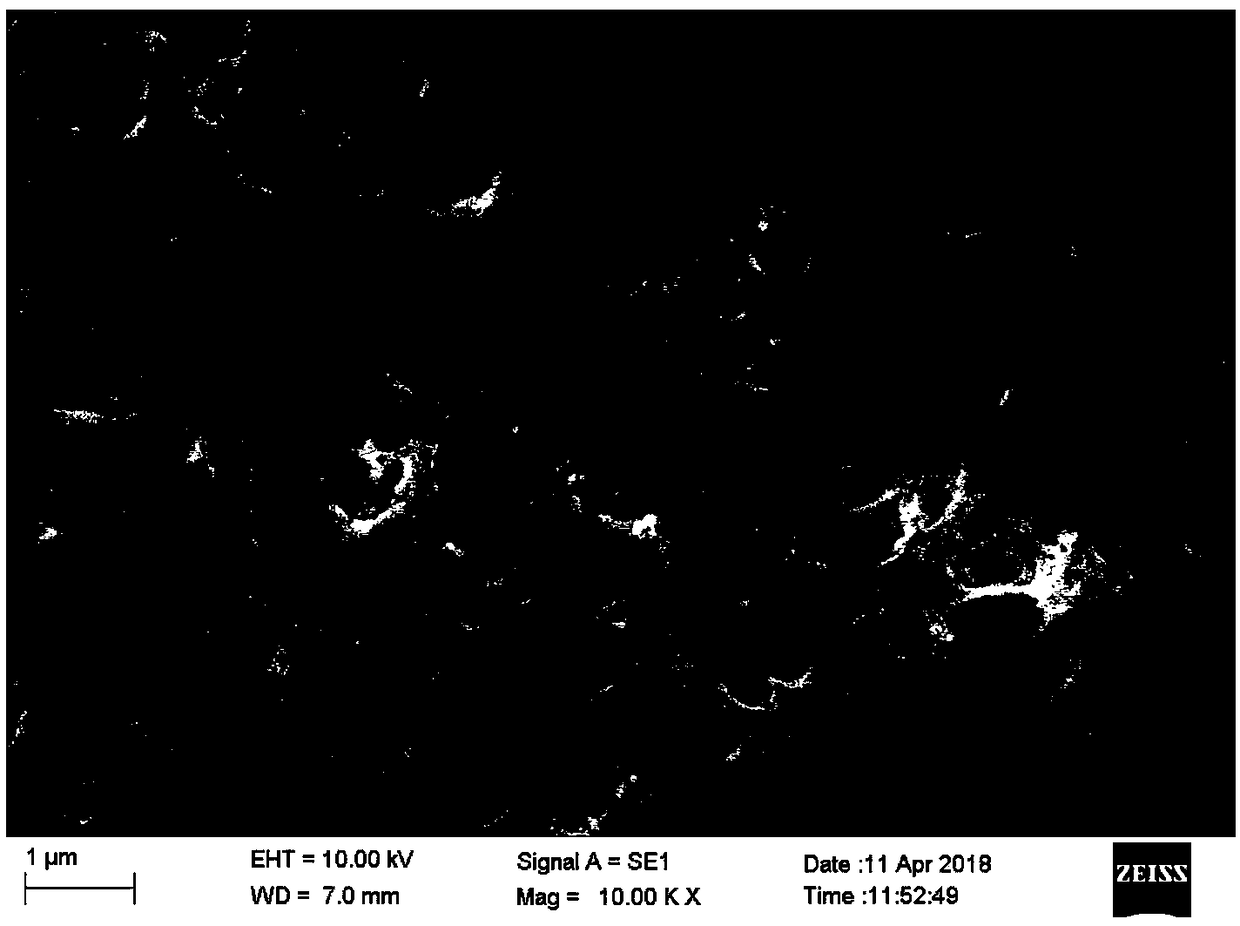

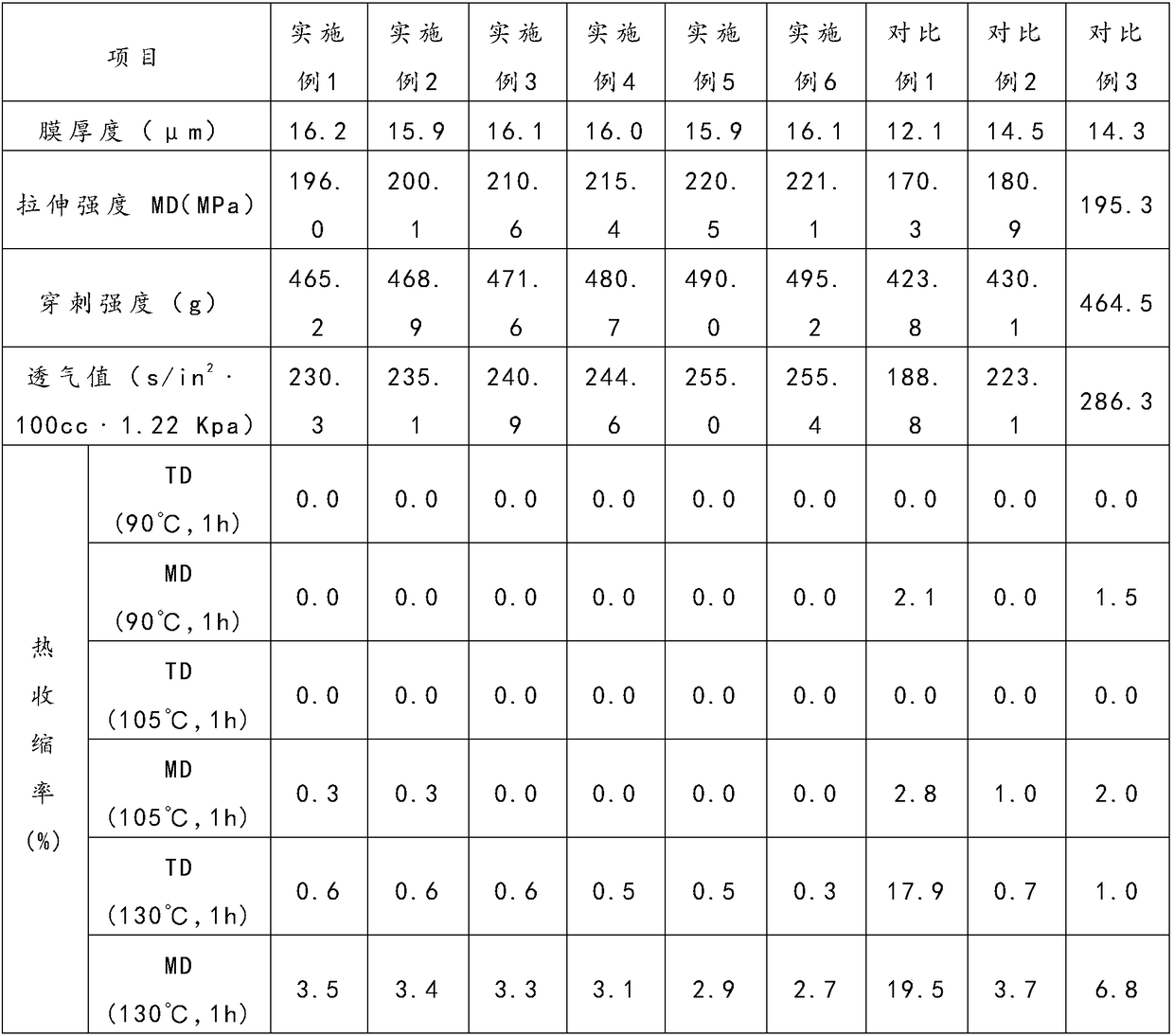

[0038] Add 20g of dispersant to 345g of water, after completely dissolving, add 5g of wetting agent, then add 100g of ceramic particles and 10g of dye, stir quickly to dissolve, then add 20g of adhesive, stir until the slurry is evenly mixed, and get the concentration 20wt% ceramic slurry. Pour the prepared slurry on a polyethylene diaphragm substrate with a thickness of 12 μm, and after coating the scraping film, dry it directly in a drying oven at 70°C for 2 hours to remove the solvent to obtain a colored ceramic coated diaphragm. figure 1 SEM image of the cross-sectional morphology of the coated base film.

[0039] Mix 2g of aramid, 10g of pore-forming agent, and 88g of N,N-dimethylacetamide (DMAc), and mechanically stir in an oil bath at 80°C for 6h until a uniform and transparent casting solution is obtained. The concentration of aramid is 2wt%. . Pour the configured aramid film casting solution on the above-mentioned film, after coating the scraping film, place it in a...

Embodiment 2

[0041] Add 25g of dispersant to 310g of water, after it is completely dissolved, add 5g of wetting agent, then add 125g of ceramic particles and 10g of dye, stir quickly to dissolve, then add 25g of adhesive, stir until the slurry is evenly mixed, and get the concentration 25wt% ceramic slurry. Pour the prepared slurry on a polyethylene diaphragm substrate with a thickness of 12 μm, and after coating the scraping film, dry it directly in a drying oven at 70°C for 2 hours to remove the solvent to obtain a colored ceramic coated diaphragm.

[0042]Mix 2g of aramid, 10g of pore-forming agent, and 88g of N,N-dimethylacetamide (DMAc), and mechanically stir in an oil bath at 80°C for 6h until a uniform and transparent casting solution is obtained. The concentration of aramid is 2wt%. . Pour the configured aramid film casting solution on the above-mentioned film, after coating the scraping film, place it in a plasticizing bath to form a film by the L-S phase inversion method, then i...

Embodiment 3

[0044] Add 20g of dispersant to 345g of water, after completely dissolving, add 5g of wetting agent, then add 100g of ceramic particles and 10g of dye, stir quickly to dissolve, then add 20g of adhesive, stir until the slurry is evenly mixed, and get the concentration 20wt% ceramic slurry. Pour the prepared slurry on a polyethylene diaphragm substrate with a thickness of 12 μm, and after coating the scraping film, dry it directly in a drying oven at 70°C for 2 hours to remove the solvent to obtain a colored ceramic coated diaphragm.

[0045] Mix 4g of aramid, 10g of pore-forming agent, and 86g of N,N-dimethylacetamide (DMAc), and mechanically stir in an oil bath at 80°C for 6h until a uniform and transparent casting solution is obtained. The concentration of aramid is 4wt%. . Pour the configured aramid film casting solution on the above-mentioned film, after coating the scraping film, place it in a plasticizing bath to form a film by the L-S phase inversion method, then immer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com