Pre-slaughter feed additive for relieving fattening pig transportation stress and improving meat quality, preparation method and application

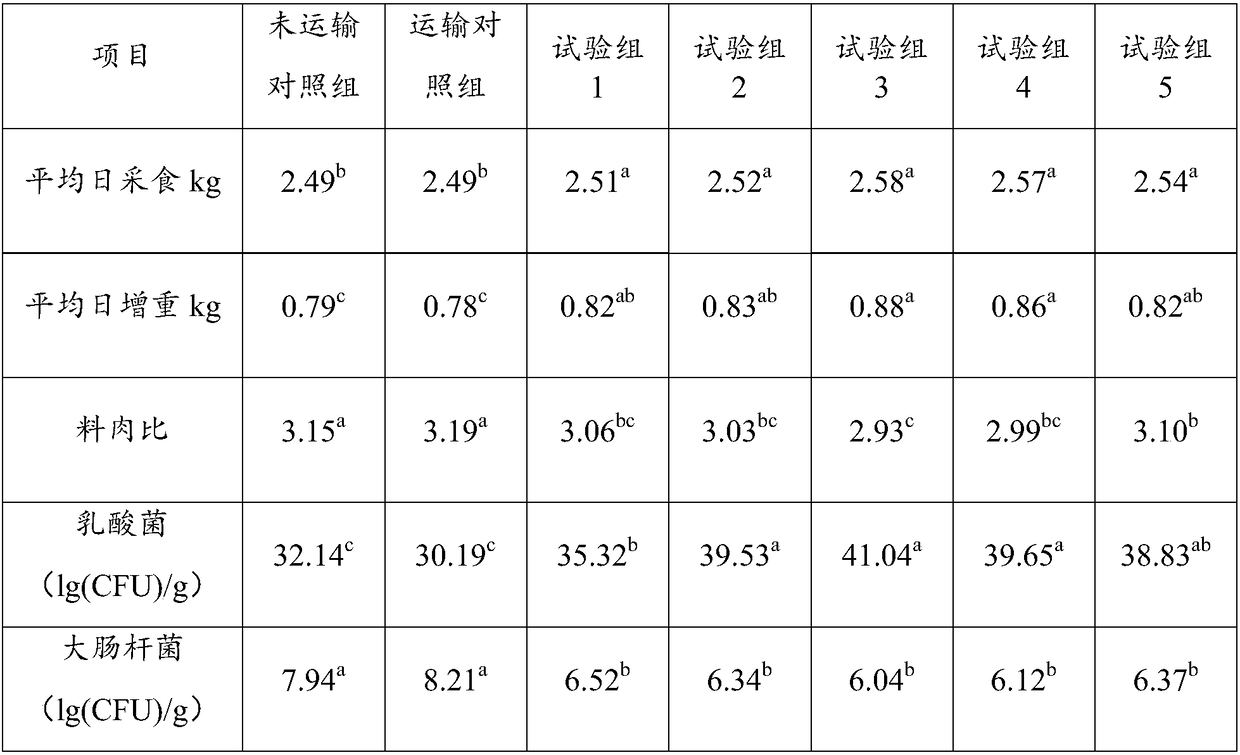

A feed additive, transportation stress technology, applied in animal feed, animal husbandry, etc., can solve the problems of reducing meat quality, aggravating skeletal muscle energy metabolism and lipid peroxidation process, etc., to improve meat quality and maintain intestinal bacteria. Group balance, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

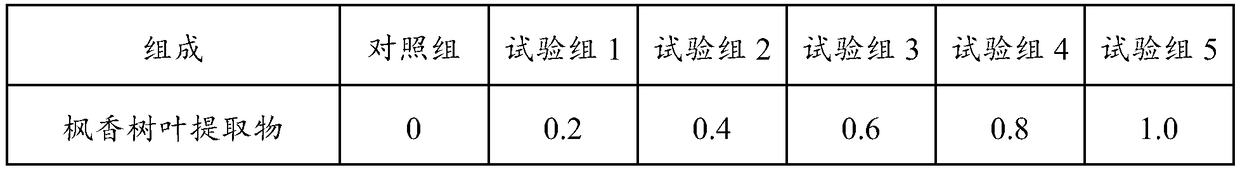

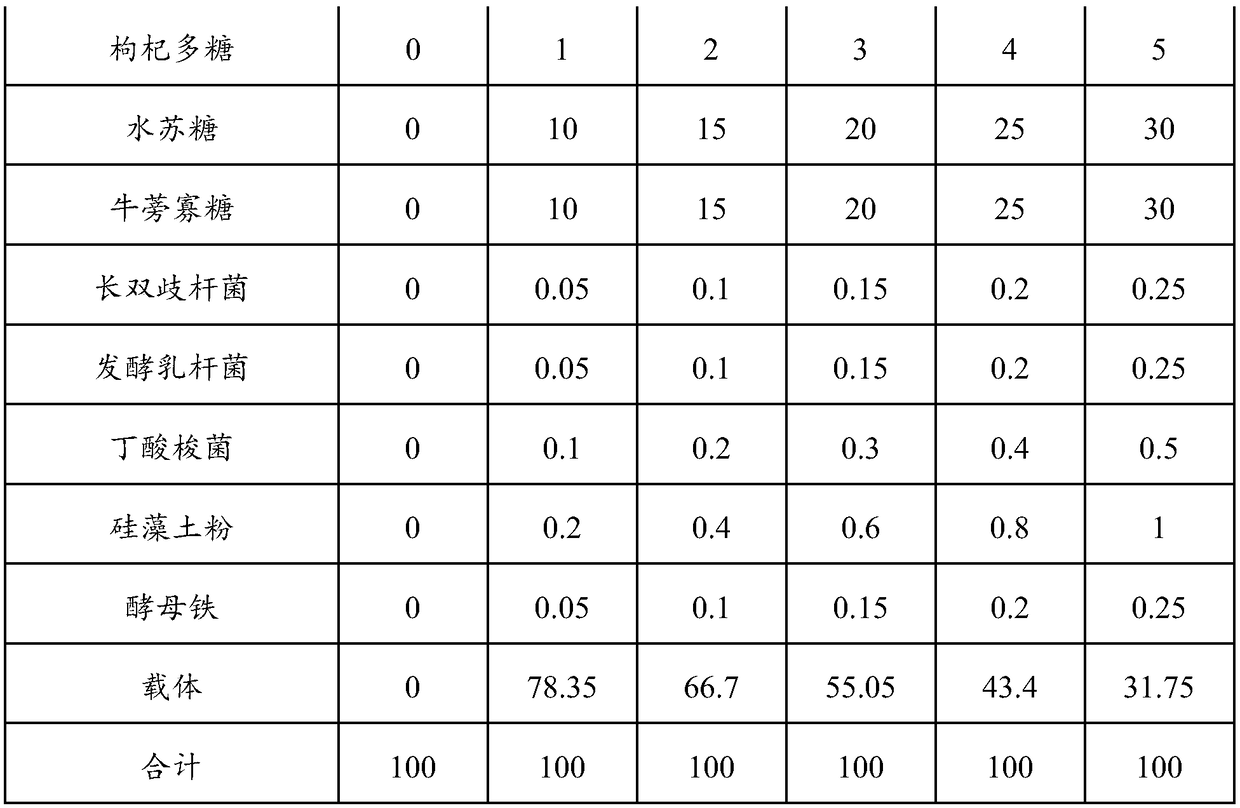

Embodiment 1

[0047] Liquidambar leaves were ultrafinely pulverized to 5 μm, and then mixed with chitosan and water at a ratio of 1g:0.4g:15mL for 5h at 55°C to remove the precipitate, and then sequentially used 20wt%, 40wt% and 60wt% Eluted with ethanol solution, collected the eluent, and dried to obtain the extract of liquidambar gum leaves.

[0048] Separately pulverize liquidambar leaf extract, wolfberry polysaccharide, stachyose, burdock oligosaccharide, yeast iron and diatomaceous earth and pass through a 100-mesh sieve. Mix 0.05 parts by weight of Bifidobacterium longum, 0.05 parts by weight of Lactobacillus fermentum, 0.1 parts by weight of Clostridium butyricum and 0.2 parts by weight of the above-mentioned diatomaceous earth to obtain the first mixture. Mix 0.2 parts by weight of the above-mentioned sweetgum gum leaf extract, 1 part by weight of the above-mentioned Lycium barbarum polysaccharide, 0.05 parts by weight of the above-mentioned yeast iron and part of the carrier to obt...

Embodiment 2

[0052] The difference between this embodiment and Example 1 is that each raw material ratio is 0.4 parts by weight of liquidambar leaf extract, 2 parts by weight of Lycium barbarum polysaccharide, 15 parts by weight of stachyose, 15 parts by weight of burdock oligosaccharide, 0.1 parts by weight Bifidobacterium longum, 0.1 part by weight of Lactobacillus fermentum, 0.2 part by weight of Clostridium butyricum, 0.4 part by weight of diatomaceous earth, 0.1 part by weight of yeast iron and 66.7 parts by weight of carrier.

Embodiment 3

[0054] The difference between this embodiment and Example 1 is that each raw material ratio is 0.6 parts by weight of liquidambar leaf extract, 3 parts by weight of Lycium barbarum polysaccharide, 20 parts by weight of stachyose, 20 parts by weight of burdock oligosaccharide, 0.15 parts by weight Parts by weight of Bifidobacterium longum, 0.15 parts by weight of Lactobacillus fermentum, 0.3 parts by weight of Clostridium butyricum, 0.6 parts by weight of diatomaceous earth, 0.15 parts by weight of yeast iron and 55.05 parts by weight of carrier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com