Manufacturing process of novel X-ray raster

A production process, X-ray technology, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of complicated process and harsh conditions, and achieve the effect of simple process conditions and convenient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

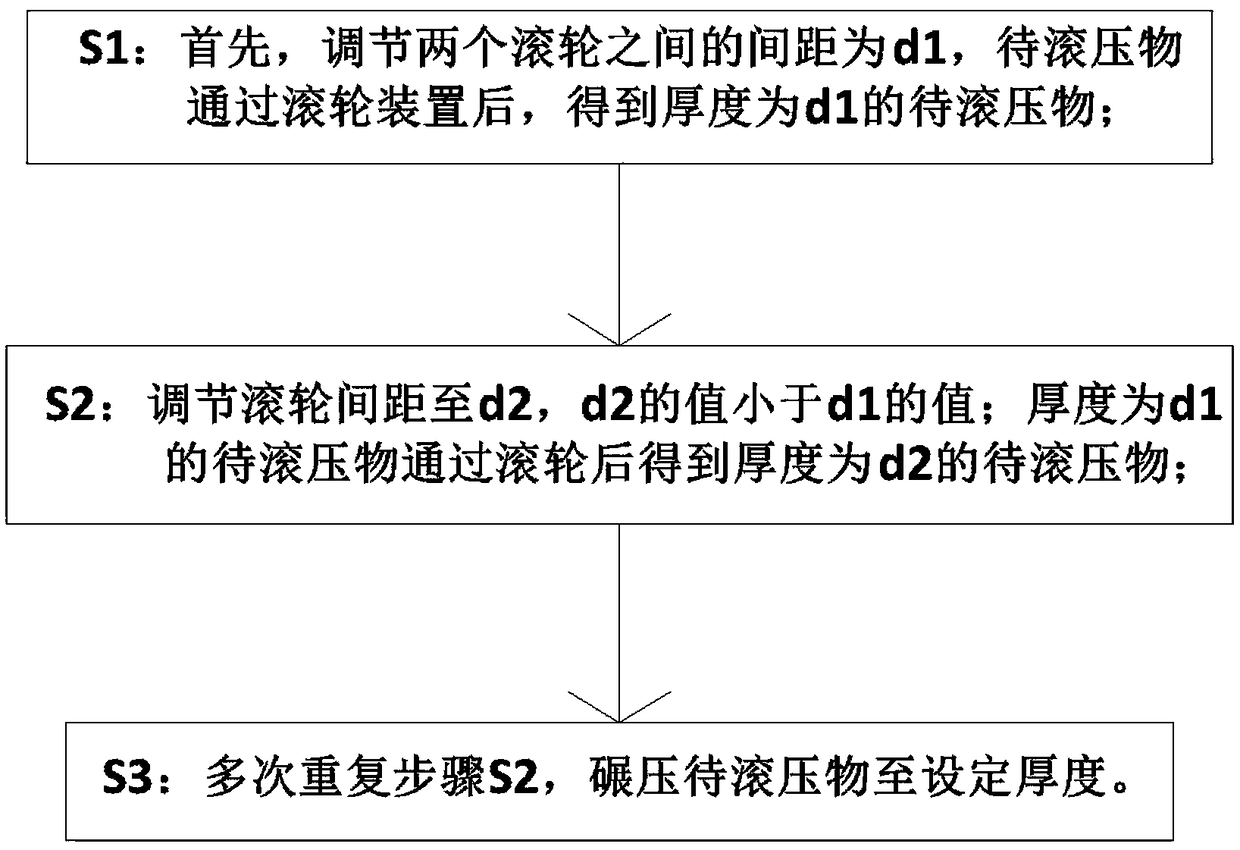

Method used

Image

Examples

Embodiment 1

[0060] Example 1: Fabrication of an absorption grating with a single grating period of 40um

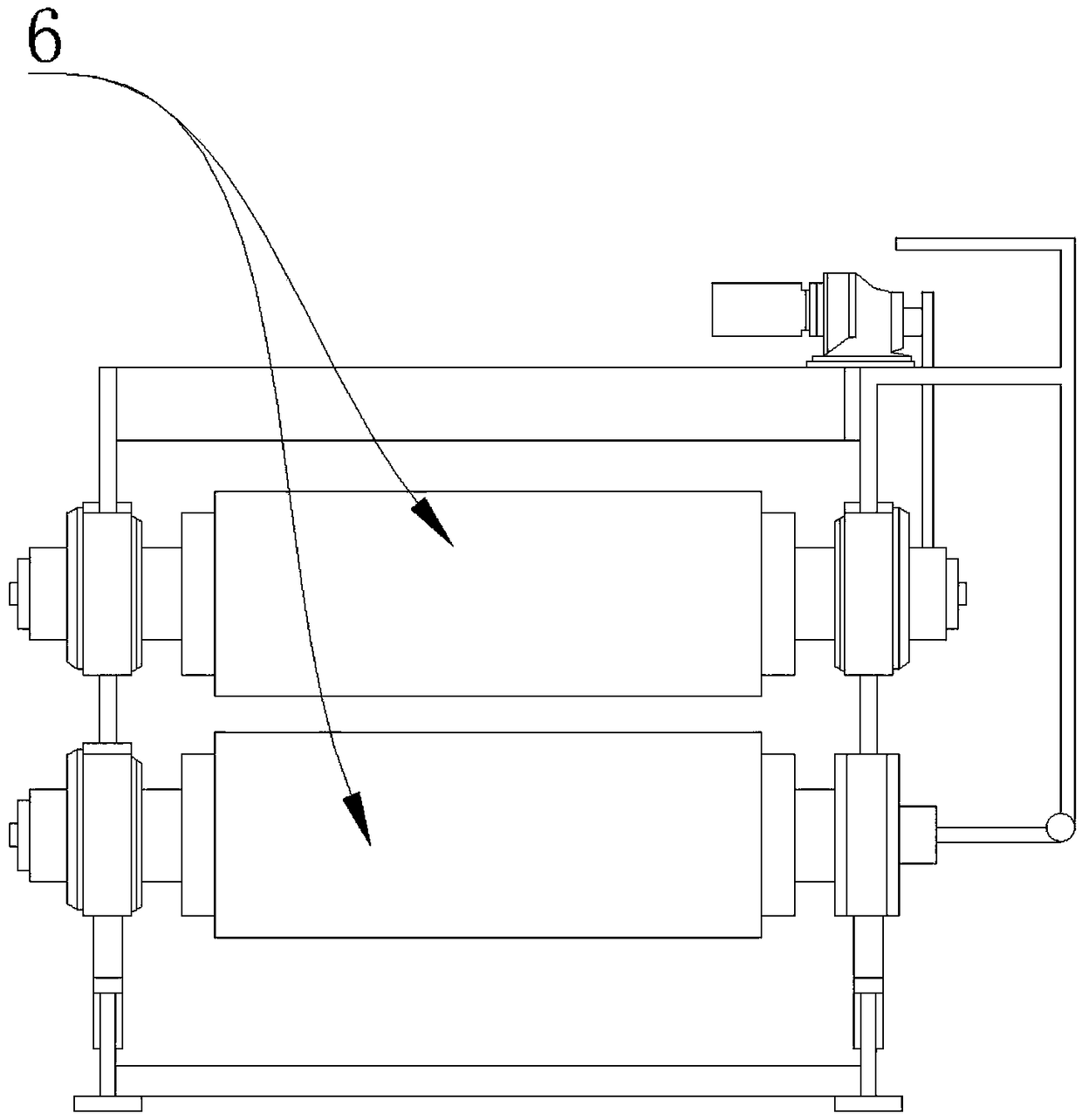

[0061] Rolling metal plates: select 3 metal lead plates with a length of 80 cm, a width of 40 cm, and a thickness of 2 cm and an aluminum metal plate with a length of 80 cm, a width of 40 cm, and a thickness of 2 cm; An aluminum plate and a lead plate are overlapped and stacked to obtain a metal plate to be rolled with a total thickness of 8cm.

[0062] Composite film production: adjust the roller spacing to 7cm, 6cm, 6.5cm, 5cm, 4.7cm, 4.5cm, 4.3cm, 4.2cm, 4.1cm, 4.096cm; the metal plate to be rolled is rolled to 4.096cm after passing the roller The composite film, the thickness ratio of heavy metal and light metal in the composite film is 3:1.

[0063] Making a composite membrane stack: stack two identical composite membranes with a thickness of 4cm to form a structure of light and heavy metal interlaced plates, and obtain a composite membrane with 2 layers and a thickness of 4.096...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com