Preparation method of low-specific surface area submicron aluminum oxide

A low specific surface area, aluminum oxide technology, applied in chemical instruments and methods, inorganic pigment treatment, dyeing physical treatment, etc., can solve the problems of α crystal form damage annealing, water (oil) value increase, fluidity deterioration, etc. , to achieve the effect of small difference in particle size and specific surface area, smooth and round product surface, and increased process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The technical scheme adopted in the present invention is:

[0033] The preparation method of submicron aluminum oxide with low specific surface area is characterized in that it comprises the following steps:

[0034] S1. Raw material selection

[0035] Use conventional calcined alumina on the market, the crystal form is α crystal form, the alumina content is greater than 99%, and the original grain size is less than 1 μm;

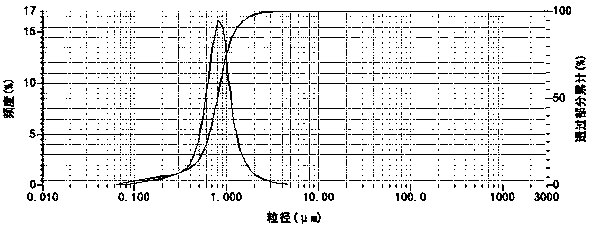

[0036] S2. Grinding

[0037] The calcined alumina is ground to a median particle size of 0.1-1 μm by wet ball milling, and the equipment used is a horizontal sand mill;

[0038] S3. drying

[0039] Spray drying wet ground alumina;

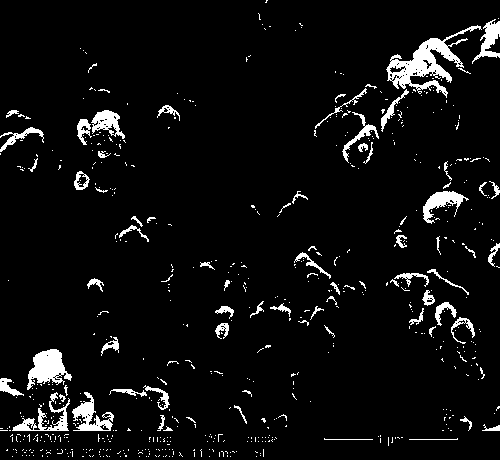

[0040] S4. Low temperature calcination

[0041] The dried alumina is calcined at 1000~1200°C; through low-temperature calcination, the rough surface after grinding is modified to be smoother and rounder, which promotes the restoration of the α crystal form and greatly reduces the specific surface area of the ground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com