Feed additive for preventing and treating diarrhea of piglets

A feed additive, piglet diarrhea technology, applied in the direction of animal feed, animal feed, plant raw materials, etc., can solve the problems of less microbial lysozyme, limited application, limited application scope, etc., and achieve good results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

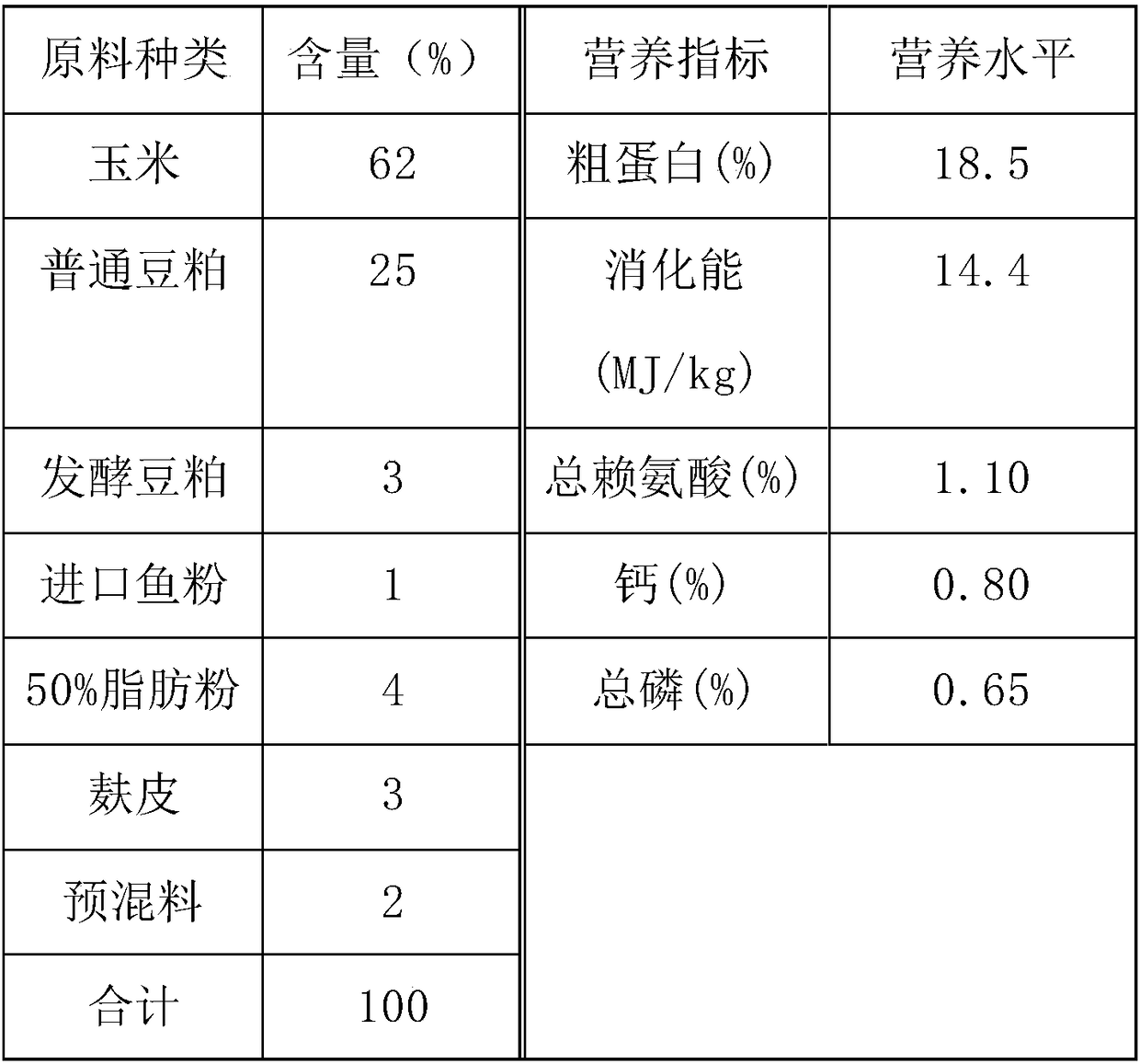

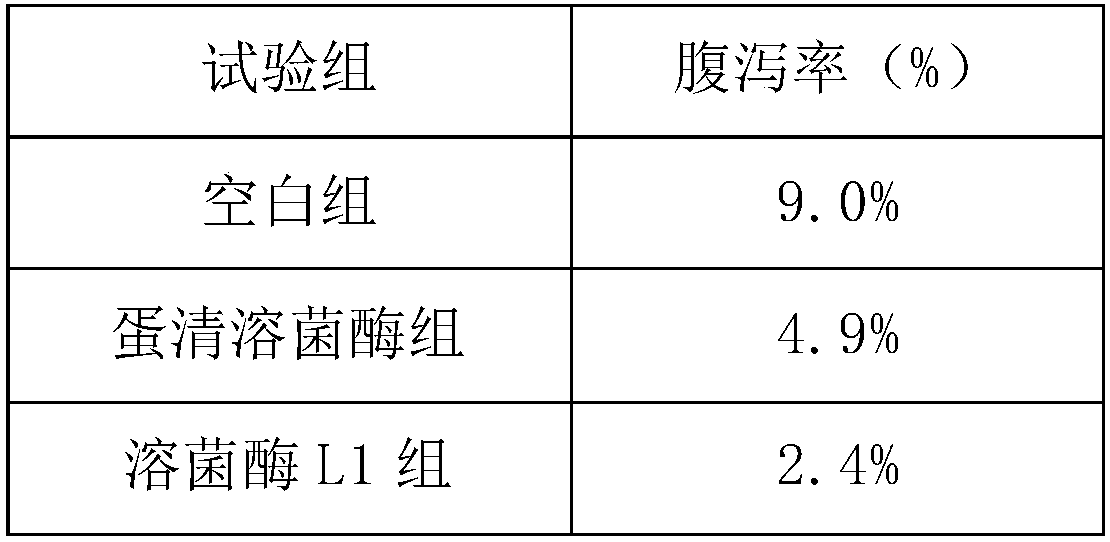

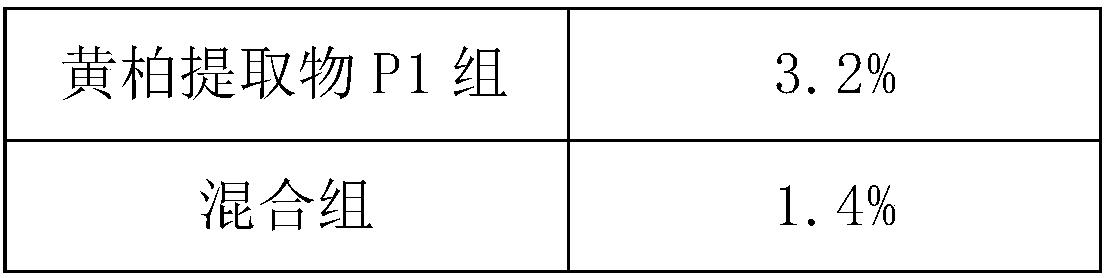

Method used

Image

Examples

Embodiment 1

[0029] Prepare liquid culture medium, wherein glucose 10g / L, peptone 5g / L. Get 25mL liquid culture medium and place in the Erlenmeyer flask, insert the thalline seed of Lysobacterium S2-6b according to the inoculum size of 4% (v / v), carry out shake flask fermentation, fermentation condition is 30 ℃, 200r / min, fermentation After cultivating for 24 hours, centrifuge the fermentation broth to remove the bacteria, take the supernatant and use ammonium sulfate salting-out method (add ammonium sulfate to the supernatant to 20% saturation, stir for 1 hour, let it stand for 1 hour, centrifuge at 10000r / min, and use it for precipitation) Dissolve in distilled water, put it into a dialysis bag with a molecular weight of 10,000, and place it in 10mmol / L PBS for full dialysis; add ammonium sulfate to the supernatant in the dialysis bag to 70% saturation, stir for 1 hour, let it stand for 1 hour, and centrifuge at 10,000r / min. The precipitate was dialyzed in the same way as above to obtain...

Embodiment 2

[0031] Prepare liquid culture medium, wherein glucose 10g / L, peptone 5g / L. Get 25mL liquid culture medium and place in the Erlenmeyer flask, insert the thalline seed of Lysobacterium S2-6b according to the inoculum amount of 4% (v / v), carry out shake flask fermentation, fermentation condition is 20 ℃, 150r / min, fermentation After cultivating for 24 hours, centrifuge the fermentation broth to remove the bacteria, take the supernatant and use ammonium sulfate salting-out method (add ammonium sulfate to the supernatant to 20% saturation, stir for 1 hour, let it stand for 1 hour, centrifuge at 10000r / min, and use it for precipitation) Dissolve in distilled water, put it into a dialysis bag with a molecular weight of 10,000, and place it in 10mmol / L PBS for full dialysis; add ammonium sulfate to the supernatant in the dialysis bag to 70% saturation, stir for 1 hour, let it stand for 1 hour, and centrifuge at 10,000r / min. Take the precipitate and dialyze, the method is the same as a...

Embodiment 3

[0033]Prepare liquid culture medium, wherein glucose 10g / L, peptone 5g / L. Get 25mL of liquid culture medium and place it in the Erlenmeyer flask, insert the thalline seed of Lysobacterium S2-6b according to the inoculum size of 4% (v / v), carry out shake flask fermentation, fermentation condition is 40 ℃, 300r / min, fermentation After cultivating for 24 hours, centrifuge the fermentation broth to remove the bacteria, take the supernatant and use ammonium sulfate salting-out method (add ammonium sulfate to the supernatant to 20% saturation, stir for 1 hour, let it stand for 1 hour, centrifuge at 10000r / min, and use it for precipitation) Dissolve in distilled water, put it into a dialysis bag with a molecular weight of 10,000, and place it in 10mmol / L PBS for full dialysis; add ammonium sulfate to the supernatant in the dialysis bag to 70% saturation, stir for 1 hour, let it stand for 1 hour, and centrifuge at 10,000r / min. The precipitate was dialyzed, and the dialysate was obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com