A kind of trapping device and process for the production of o-chlorobenzonitrile

A technology of o-chlorobenzonitrile and process, which is applied in the field of trapping devices for the production of o-chlorobenzonitrile, can solve problems such as harsh working environment, continuous discharge, and high labor intensity of workers, and achieves improved site environment, automatic continuous The effect of discharging materials and reducing labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

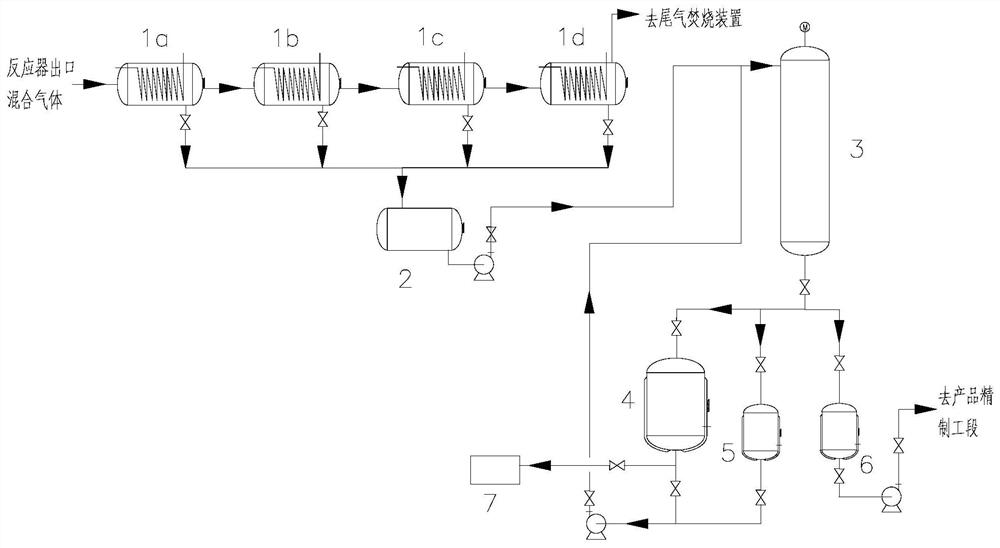

[0028] Such as figure 1 As shown, the trapping device used for the production of o-chlorobenzonitrile includes a multi-stage trap melter, including four stages in this embodiment: a primary trap melter 1a, a secondary trap melter 1b, and a third stage Capture melter 1c, four-stage capture melter 1d, middle tank 2, liquid separator 3, water phase receiving tank 4, floc receiving tank 5, organic phase receiving tank 6; all levels of capture melters are connected in series , and the trapping melters at all levels are connected to the middle tank 2, the middle tank 2 is connected to the liquid separator 3 through the pump, and the liquid separator 3 is respectively connected to the parallel water phase receiving tank 4, the floc receiving tank 5 and the organic phase receiving tank 6. The outlet of the last-stage trapping melter is connected to a tail gas incineration device.

[0029] The trapping melters at all levels are equipped with jackets and coils. The inner walls and coi...

Embodiment 2

[0033] The capture process for the production of o-chlorobenzonitrile, the reaction mixed gas at the outlet of the 230°C oil cooler passes through the first, second, third and fourth capture melters in sequence, and the inner wall and disc of the capture melter at each level Tube material is stainless steel. At this time, the jackets and coils of the four trapping melters were fed with low-temperature water at a temperature of 15° C., and gaseous o-chlorobenzonitrile was precipitated on the inner wall and coil surface of the four trapping melters and became solid. The temperature of the tail gas at the outlet of the fourth-stage capture melter is controlled at 40°C, and the tail gas enters the tail gas incinerator for treatment. After the capture process is completed, hot water with a temperature of 50°C is passed through the jackets and coils of the four capture melters for 0.5 hours, and the solid o-chlorobenzonitrile is heated and melted into a liquid state and then enters ...

Embodiment 3

[0036]The capture process for the production of o-chlorobenzonitrile, the reaction mixed gas at the outlet of the 230°C oil cooler passes through the first, second, third and fourth capture melters in sequence, and the inner wall and disc of the capture melter at each level Tube material is stainless steel. At this time, the temperature in the jackets and coils of the four trapping melters is -5°C chilled water, and gaseous o-chlorobenzonitrile is precipitated on the inner wall and coil surface of the four trapping melters and becomes solid. The temperature of the tail gas at the outlet of the fourth-stage capture melter is controlled at 10°C, and the tail gas enters the tail gas incinerator for treatment. After the capture process is completed, the jackets and coils of the four capture melters pass hot water at a temperature of 50°C for 0.5 hours. The solid o-chlorobenzonitrile is heated and melted into a liquid state and then enters the middle tank. The mixture of the aqueo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com