Porous organic material/polymer composite membrane and its preparation method and application

A technology of porous organic materials and polymer membranes, applied in chemical instruments and methods, membrane technology, semipermeable membrane separation, etc., can solve the problems of poor compatibility and easy agglomeration of porous materials, and achieve the goal of overcoming poor compatibility and compatibility Good performance, improve the effect of pervaporation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

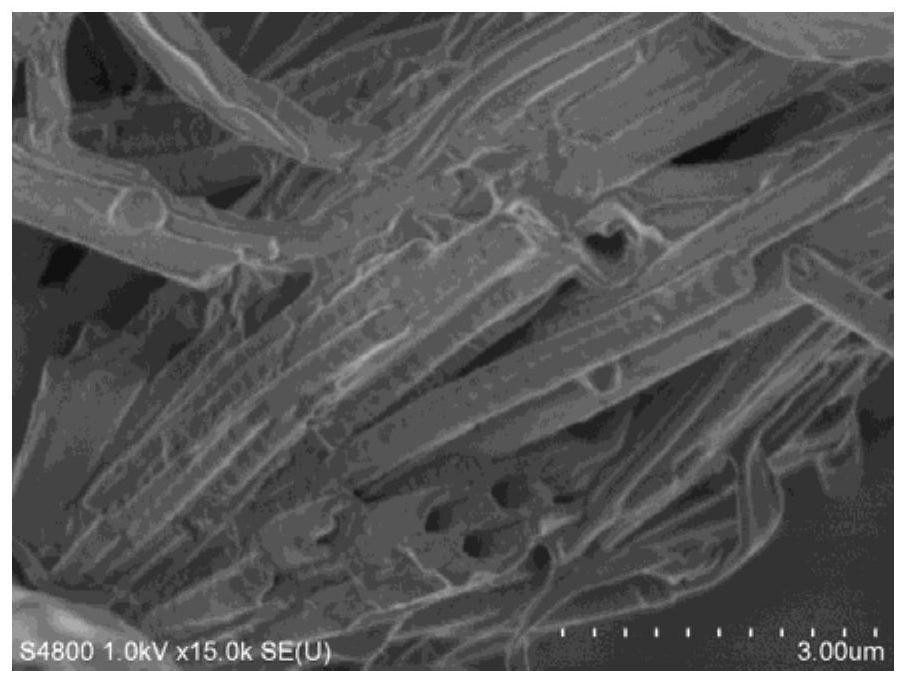

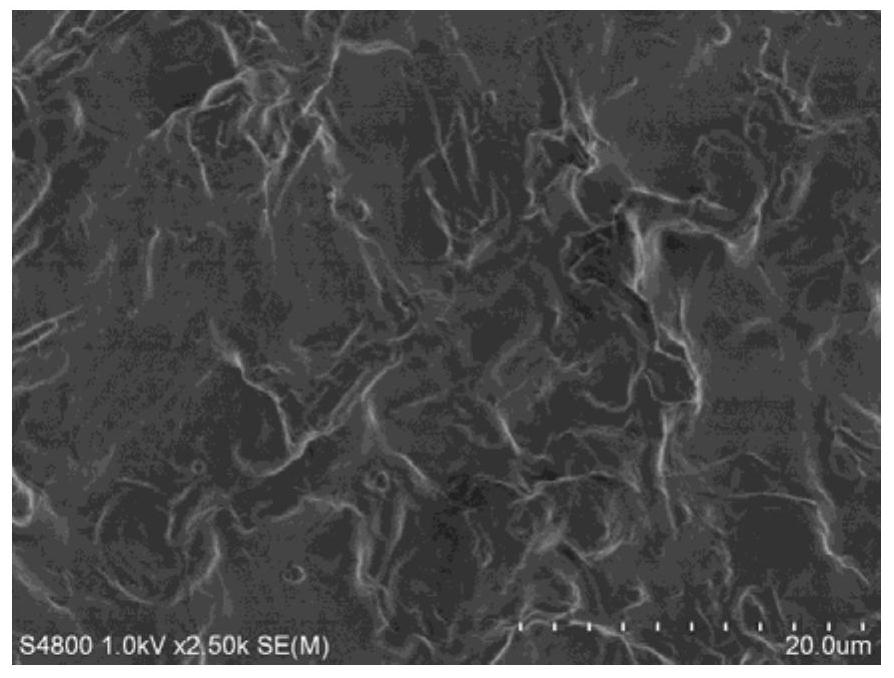

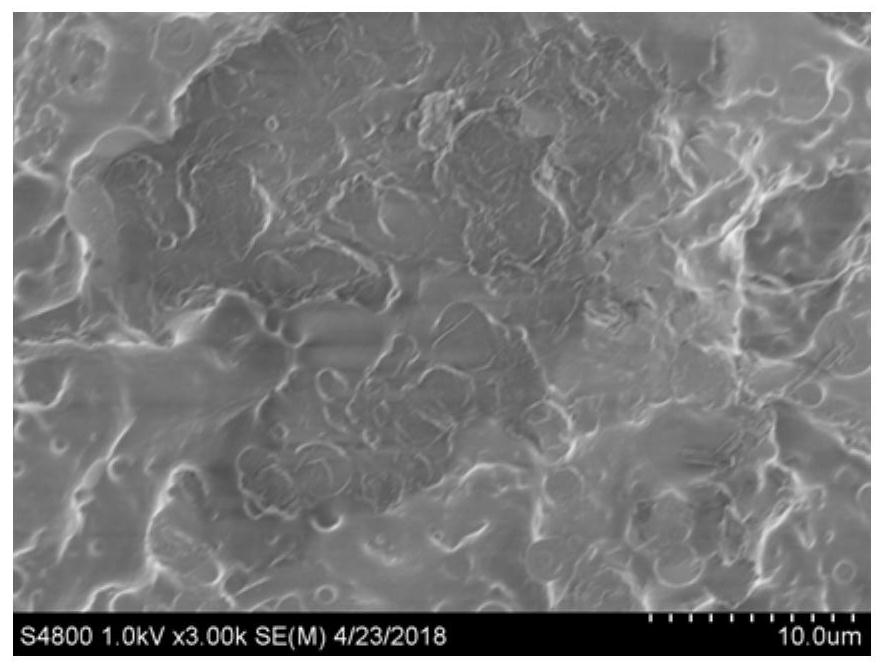

Image

Examples

preparation example Construction

[0038] The preparation method of porous organic material / polymer composite membrane comprises the following steps:

[0039] (1) dissolving the aromatic reactants and adding a catalyst, condensing and refluxing at 50-80°C, heating and stirring for 6-24 hours, ultrasonically washing with different solvents and filtering the product, and drying to obtain the porous organic material;

[0040] (2) Add the polymer membrane material into the organic solvent, stir at 50-90°C to form a membrane material solution, take another organic solvent, and ultrasonically disperse the porous organic material in it to form a uniform suspension, and then the membrane Mix the material solution and the suspension, and continue to stir at 50-90°C until uniform to form a casting solution, and let it stand for defoaming;

[0041] (3) Scraping and forming the casting solution to obtain the porous organic material / polymer composite membrane.

[0042] Preferably, in step (1):

[0043] Aromatic reactants ...

Embodiment 1

[0054] A porous organic material / polymer composite membrane, which comprises polymer membrane material and porous organic material dispersed therein. The porous organic material is a hypercrosslinked polymer prepared by the reaction of aromatic reactants under the action of a catalyst. The polymer membrane material is polyether block copolyamide (PEBA). The mass fraction of the porous organic material in the composite membrane is 1 ~30%, the composite membrane can be applied to the pervaporation of phenol-containing solution preferentially permeating phenol. The specific preparation steps of the composite membrane are as follows:

[0055] (1) Preparation of porous organic materials

[0056] Weigh 40mmol benzyl alcohol, add a certain amount of dichloroethane to dissolve, weigh 80mmol anhydrous ferric chloride and add it to the reactant, heat and stir at constant temperature, N 2 Protect and add condensation to reflux for 12h. After the reaction, the product was filtered, wash...

Embodiment 2

[0063] A porous organic material / polymer composite membrane, which comprises polymer membrane material and porous organic material dispersed therein. The porous organic material is a super-crosslinked polymer prepared by aromatic reactants under the action of a catalyst. The polymer film material is polyurethane (PU). The mass fraction of the porous organic material in the composite film is 1 to 30%. The composite film It can be applied in pervaporation separation where phenol-containing solution preferentially permeates phenol. The specific preparation steps of the composite membrane are as follows:

[0064] (1) Preparation of porous organic materials

[0065] Weigh 40mmol benzyl alcohol, add a certain amount of dichloroethane to dissolve, weigh 80mmol anhydrous ferric chloride and add it to the reactant, heat and stir at constant temperature, N 2 Protect and add condensation to reflux for 12h. After the reaction, the product was filtered, washed with tetrahydrofuran, hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com