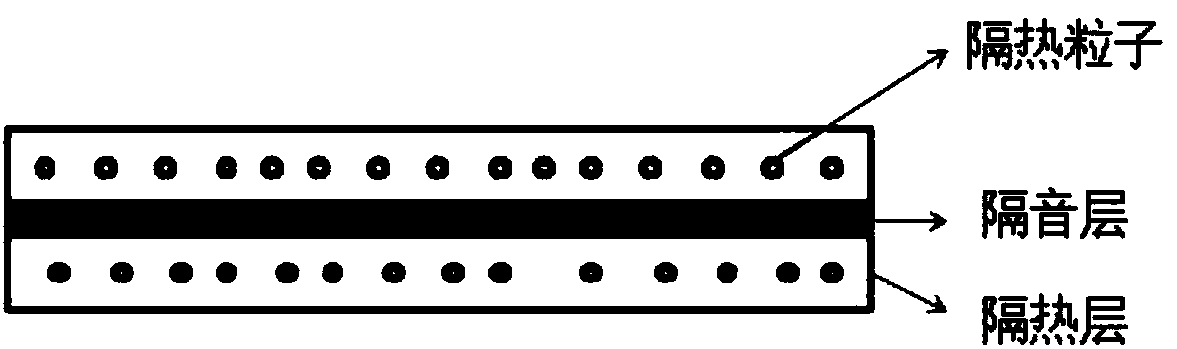

Heat-insulating and sound-insulating PVB film and preparation method thereof

A heat and sound insulation and film technology, applied in chemical instruments and methods, other household appliances, applications, etc., can solve the problems of low light transmittance, poor heat insulation effect, and poor sound insulation of heat and sound insulation PVB film, and achieve super The effect of strong mid-infrared blocking and reflecting ability, production process optimization, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

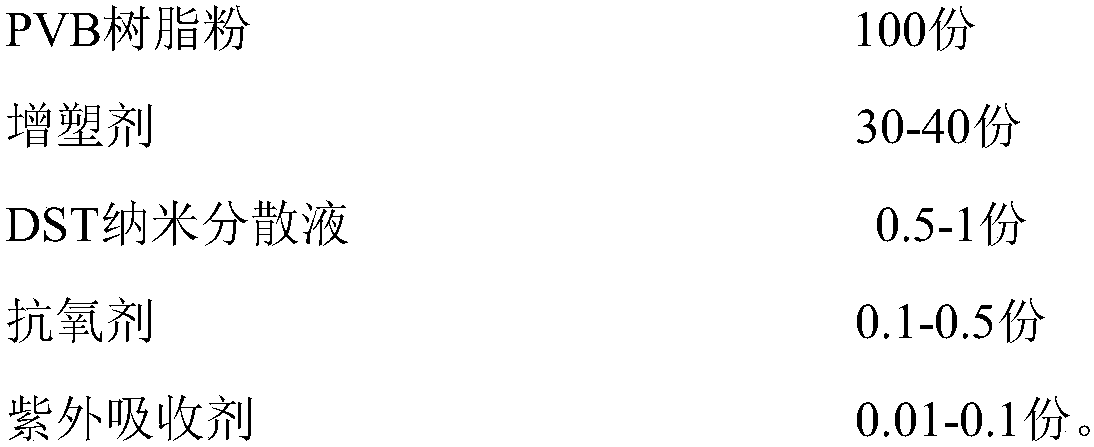

Method used

Image

Examples

Embodiment 1

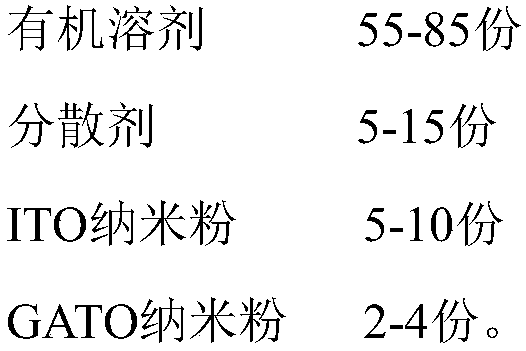

[0048] (1) Preparation of heat-insulating DST dispersion: Take 8.5kg of organic solvent triethylene glycol diisocaprylate, 0.8kg of nano-ITO powder and 0.2kg of nano-GATO powder and mix them together. During slow grinding, add 0.5kg of dispersant Agent silane coupling agent 6598, and continue to grind on the ball mill for 24 hours to obtain nano-DST dispersion.

[0049] (2) In the first layer and the third layer extruder, 100kgPVB resin, 0.25kg antioxidant mixture (from 266.8g tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) Propionic acid] pentaerythritol ester and 133.2g three [2,4-di-tert-butylphenyl] phosphite composition), 0.05kg ultraviolet absorber mixture (by 50g2-(2'-hydroxyl-5'-tert-octyl)-benzene Triazole and 50g 2-(2′-hydroxyl-5′-methyl)-benzotriazole) were added to the powder mixer and stirred at a high speed at 1000RPM for 20 minutes. Control the temperature of the equipment so that the temperature of the material during the stirring process is between 40°C and 5...

Embodiment 2

[0051] (1) Preparation of heat-insulating DST dispersion: Take 8.5kg of organic solvent triethylene glycol diisocaprylate, 0.8kg of nano-ITO powder and 0.2kg of nano-GATO powder and mix them together. During slow grinding, add 0.5kg of dispersant Agent silane coupling agent 6598, and continue to grind on the ball mill for 24 hours to obtain nano-DST dispersion.

[0052] (2) In the first layer and the third layer extruder, 100kgPVB resin, 0.25kg antioxidant mixture (from 266.8g tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) Propionic acid] pentaerythritol ester and 133.2g three [2,4-di-tert-butylphenyl] phosphite composition), 0.05kg ultraviolet absorber mixture (by 50g2-(2'-hydroxyl-5'-tert-octyl)-benzene Triazole and 50g 2-(2′-hydroxyl-5′-methyl)-benzotriazole) were added to the powder mixer and stirred at a high speed at 1000RPM for 20 minutes. Control the temperature of the equipment so that the temperature of the material during the stirring process is between 40°C and 5...

Embodiment 3

[0054] (1) Preparation of heat-insulating DST dispersion: Take 8.5kg of organic solvent triethylene glycol diisocaprylate, 0.8kg of nano-ITO powder and 0.2kg of nano-GATO powder and mix them together. During slow grinding, add 0.5kg of dispersant Agent silane coupling agent 6598, and continue to grind on the ball mill for 24 hours to obtain nano-DST dispersion.

[0055] (2) In the first layer and the third layer extruder, 100kgPVB resin, 0.25kg antioxidant mixture (from 266.8g tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) Propionic acid] pentaerythritol ester and 133.2g three [2,4-di-tert-butylphenyl] phosphite composition), 0.05kg ultraviolet absorber mixture (by 50g2-(2'-hydroxyl-5'-tert-octyl)-benzene Triazole and 50g 2-(2′-hydroxyl-5′-methyl)-benzotriazole) were added to the powder mixer and stirred at a high speed at 1000RPM for 20 minutes. Control the temperature of the equipment so that the temperature of the material during the stirring process is between 40°C and 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com