A kind of preparation method of micro-mesoporous ZSM-5 molecular sieve

A technology of ZSM-5 and molecular sieve, which is applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of environmental pollution and high price, and achieve low economic cost, simple operation, The effect of mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

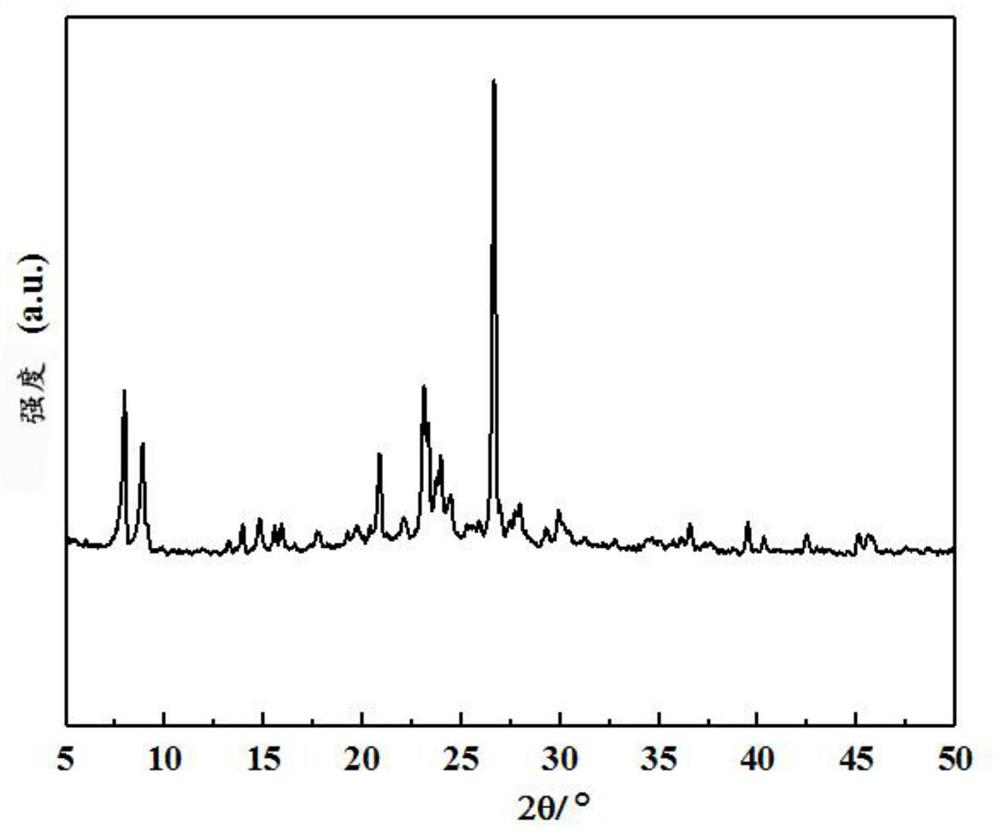

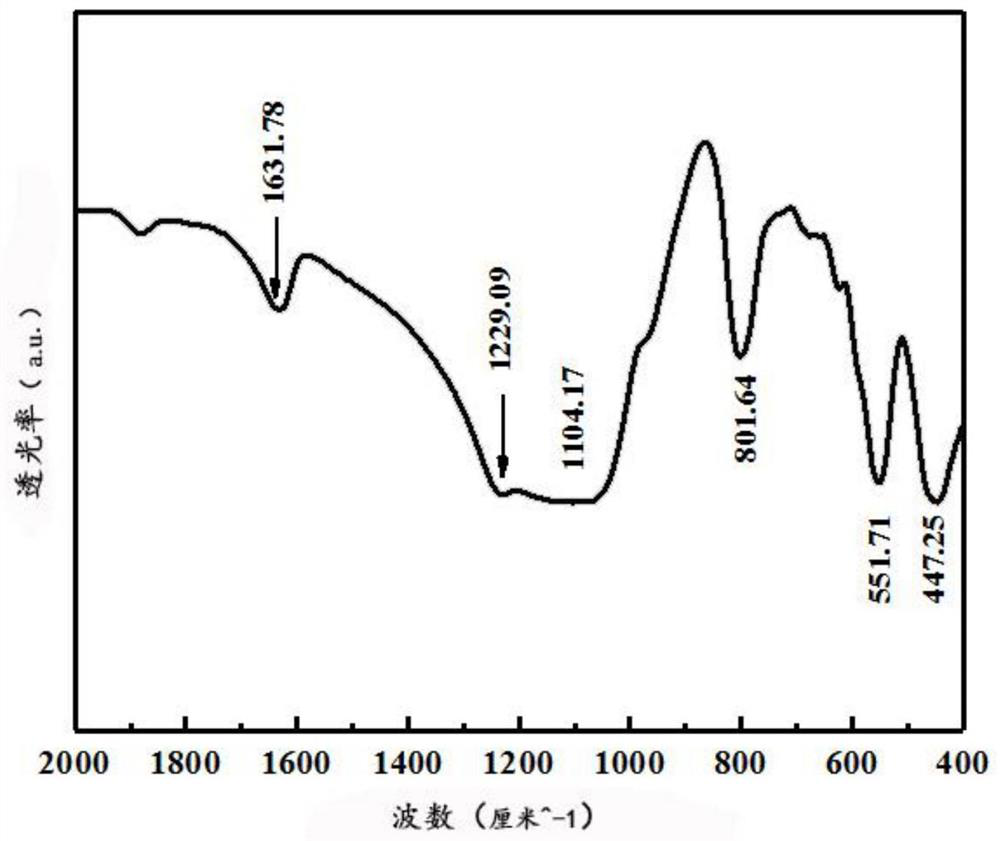

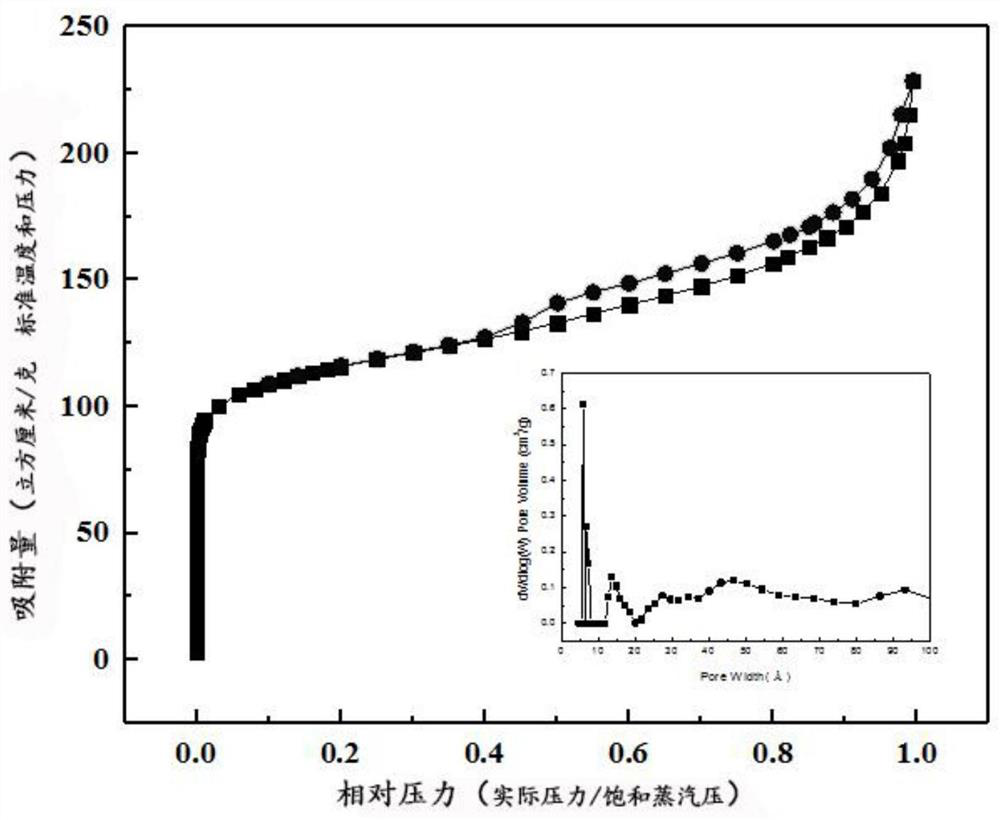

[0030] A method for preparing micro-mesoporous ZSM-5 molecular sieves, using attapulgite after alkali-acid pretreatment as a silicon source, ammonia water as a template agent, sodium hydroxide as a post-treatment pore-forming agent, and aluminum sulfate octadecahydrate as supplementary aluminum Source, synthesized by hydrothermal crystallization method, specifically according to the steps:

[0031] Step 1, the attapulgite is subjected to alkali-acid pretreatment to obtain silicon source powder, specifically according to the following steps:

[0032] Step 1.1, mix powdered attapulgite and sodium hydroxide with a mass ratio of 1:1, calcinate at a high temperature of 550°C for 2 hours, take out and grind after cooling to obtain a mixture, add water to the mixture and stir evenly, After drying and cooling, add a sodium chloride solution with a concentration of 1mol / L and mix evenly, wherein the mass volume ratio of the mixture to the sodium chloride solution is 1g:10mL, filter wit...

Embodiment 1

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0044] A method for preparing micro-mesoporous ZSM-5 molecular sieves, using attapulgite after alkali-acid pretreatment as a silicon source, ammonia water as a template agent, sodium hydroxide as a post-treatment pore-forming agent, and aluminum sulfate octadecahydrate as supplementary aluminum Source, synthesized by hydrothermal crystallization method, specifically according to the steps:

[0045] Step 1, the attapulgite is subjected to alkali-acid pretreatment to obtain silicon source powder, specifically according to the following steps:

[0046] Step 1.1, mix powdered attapulgite and sodium hydroxide with a mass ratio of 1:1, calcinate at a high temperature of 550°C for 2 hours, take out and grind after cooling to obtain a mixture, add water to the mixture and stir evenly, After drying and cooling, add a sodium chloride solution with a c...

Embodiment 2

[0052] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0053] A method for preparing micro-mesoporous ZSM-5 molecular sieves, using attapulgite after alkali-acid pretreatment as a silicon source, ammonia water as a template agent, sodium hydroxide as a post-treatment pore-forming agent, and aluminum sulfate octadecahydrate as supplementary aluminum Source, synthesized by hydrothermal crystallization method, specifically according to the steps:

[0054] Step 1, the attapulgite is subjected to alkali-acid pretreatment to obtain silicon source powder, specifically according to the following steps:

[0055] Step 1.1, mix powdered attapulgite and sodium hydroxide with a mass ratio of 1:1, calcinate at a high temperature of 550°C for 2 hours, take out and grind after cooling to obtain a mixture, add water to the mixture and stir evenly, After drying and cooling, add a sodium chloride solution with a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com