Glass, its preparation method and application

A glass and glass tube technology, applied in its preparation and glass field, can solve the problems of reducing the service life of molding equipment, product streak defects, product stones, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

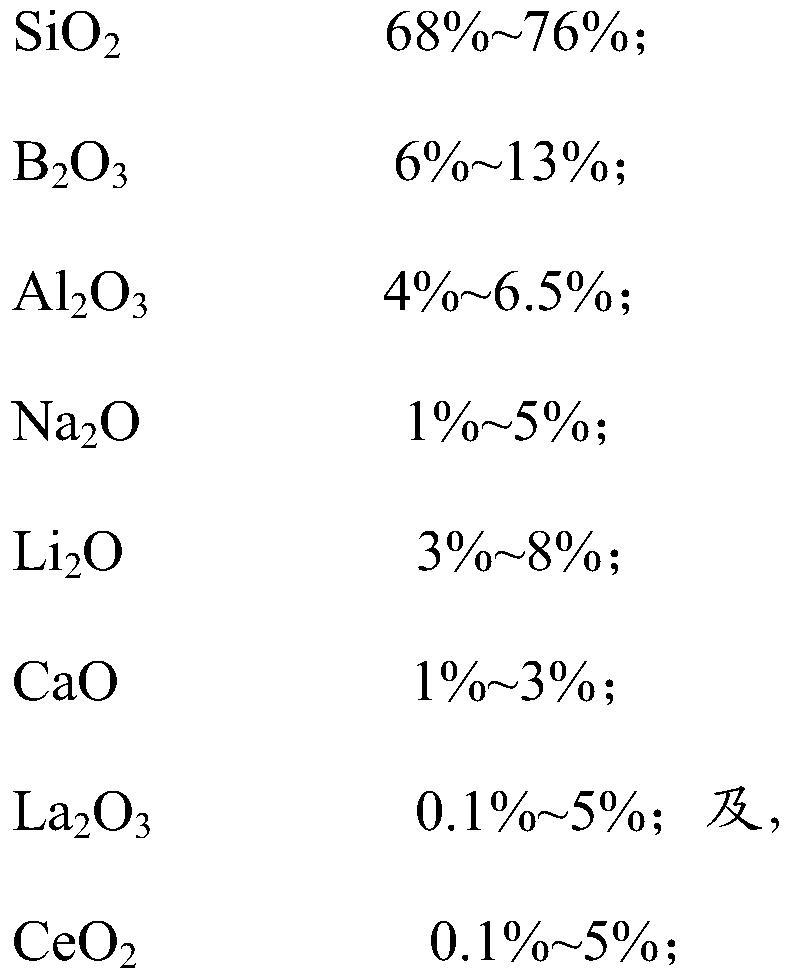

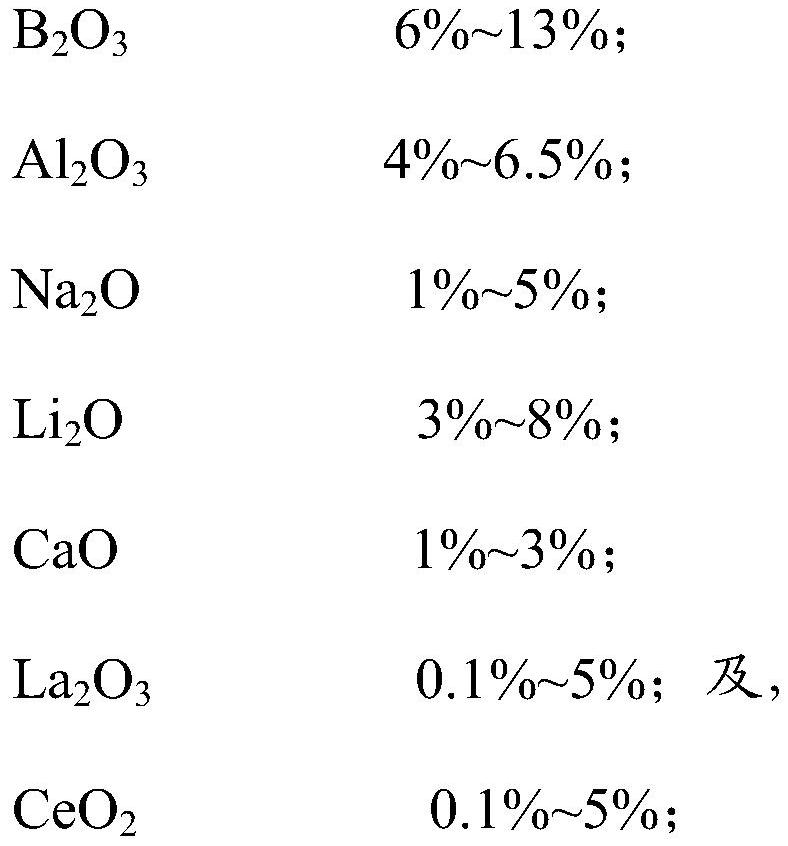

Method used

Image

Examples

Embodiment 1~18

[0050] For the glasses of Examples 1-18, the corresponding raw materials were weighed according to the proportions in Table 1, and mixed uniformly in a mixer to obtain a mixture, which was transported to the kiln head warehouse through a conveyor belt conveyor and a bucket elevator. Then put the mixture into the flame kiln, melt and clarify at 1650°C to form a homogeneous molten glass, and then rise to the platinum forehearth through the flow hole to cool down. Then the molten glass at 1230°C flows out from the feeding nozzle and winds on the rotating tube rotating at low speed. Under the action of the mandrel wind, the molten glass at the end of the rotating tube forms a hollow circular glass tube, and then the Under the action, the glass tube is gradually cooled along the runway, and then it is rough cut and finely cut to grow into a medicinal glass tube with a diameter of 15mm and a wall thickness of 1.5mm. Finally, the glass tube completes the control bottle process throug...

Embodiment 1

[0059] Embodiment 14 is the comparative example of embodiment 1, Li 2 When the O content drops to 0, the B volatilization increases to 18.3%, and the thermal expansion coefficient increases to 5.66*10 -6 K -1 . Embodiment 15 is the comparative example of embodiment 2, La 2 o 3 When the content is reduced to 0, the volatilization of B increases to 15.7%. Embodiment 16 is a comparative example of embodiment 3, Li 2 O and La 2 o 3 When the contents are all 0, the volatile amount of B is 20.1%. Embodiment 17,18 is the comparative example of embodiment 7, Li 2 When the O content was 0 and 1.5%, the volatilization of B was greater than 15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com