Water-repellent oilproof antistatic woven ribbon

A water-repellent, oil-repellent, anti-static technology, applied in the manufacture of conductive/anti-static filaments, decorative textiles, textiles and papermaking, etc., can solve the problems of dirty slings, affect use, surface slippage, etc., and achieve excellent processing performance , Conducive to environmental protection, improve the effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

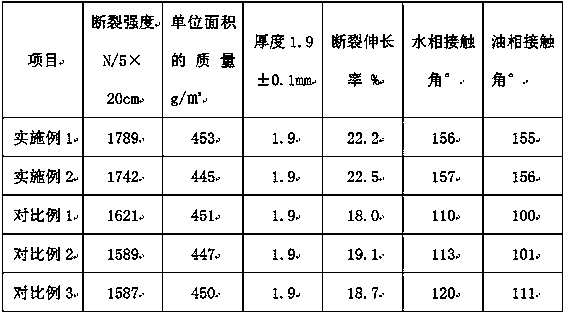

Examples

Embodiment 1

[0014] A water-repellent and oil-repellent antistatic webbing, which contains the following components: 80 parts of polyamide, 50 parts of bamboo fiber, 20 parts of PET, 5 parts of carbon nanotubes, 20 parts of chlorinated polyether, 5 parts of carbon fiber, 3 parts of glass fiber , 1 part of magnesium sulfate whisker, 12 parts of ion-modified clay, 2 parts of coupling agent, 2 parts of antistatic agent, 2 parts of anti-aging agent, 0.5 part of water and oil repellent, 0.5 part of cleaning additive.

[0015] Further, the water and oil repellent is made by uniformly mixing a fluorine-containing compound and ethanol in a weight ratio of 1:80~1:60, wherein the fluorine-containing compound is 1H, 1H, 2H, 2H-perfluorododecane mercaptan, ten One or more of trifluorooctyl propyl cage silsesquioxane and tridecafluorooctyl triethoxy silane.

[0016] Further, the cleaning additive is composed of 2 parts of nano inorganic substance, 30 parts of solvent, 1 part of coupling agent, and 13 parts ...

Embodiment 2

[0019] A water-repellent, oil-repellent and antistatic webbing comprising the following components: 50 parts of polyamide, 50 parts of bamboo fiber, 10-20 parts of PET, 2 parts of carbon nanotubes, 20 parts of chlorinated polyether, 5 parts of carbon fiber, and glass fiber 3 parts, 1 part of magnesium sulfate whisker, 2 parts of ion-modified clay, 2 parts of coupling agent, 2 parts of antistatic agent, 2 parts of anti-aging agent, 0.5 part of water and oil repellent agent, 0.5 part of cleaning additive.

[0020] Further, the water and oil repellent is made by uniformly mixing a fluorine-containing compound and ethanol in a weight ratio of 1:60, wherein the fluorine-containing compound is 1H, 1H, 2H, 2H-perfluorododecyl mercaptan, tridecafluorooctyl One or more of propyl cage silsesquioxane and tridecafluorooctyl triethoxysilane.

[0021] Further, the cleaning additive is composed of 2 parts of nano inorganic substance, 30 parts of solvent, 1 part of coupling agent, and 13 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com