Method for preparing lithium-replenishing material Li2NiO2, and lithium ion capacitor using Li2NiO2

A technology for capacitors and lithium ions, which is applied in the preparation of lithium-supplementing materials Li2NiO2 and the field of lithium-ion capacitors using the Li2NiO2, which can solve the problems of high production cost of porous foil materials, weakened capacitor power characteristics, and hidden dangers of lithium metal safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

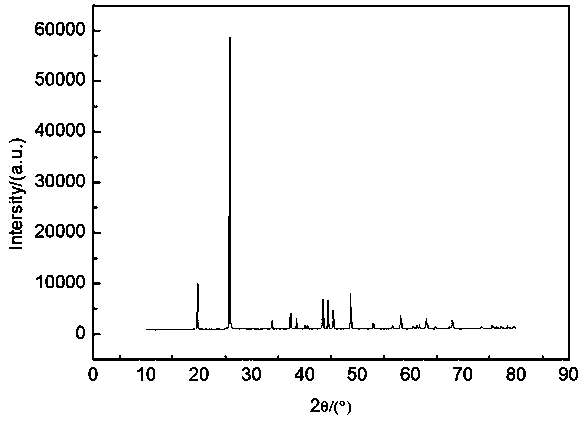

[0034] Will Li 2 O, NiO according to the molar ratio of 1:1, in N 2 Under the protection of ball milling for 12h, before sintering, pass N into the furnace 2 20min, remove the oxygen in the furnace, heat up to 600°C at a heating rate of 10°C / min, and sinter for 10h, take it out, grind it, and get Li 2 NiO 2 Crude product, take Li 2 NiO 2 Crude product mass 3% Al 2 o 3 with Li 2 NiO 2 The crude product was ball milled for 5 hours, the temperature was raised to 600°C at a heating rate of 10°C / min, and the sintering time was 10h to obtain the lithium-replenishing material Li 2 NiO 2 ,spare. The lithium supplement material Li 2 NiO 2 The XRD pattern (X-ray diffraction pattern) see figure 1 .

Embodiment 2

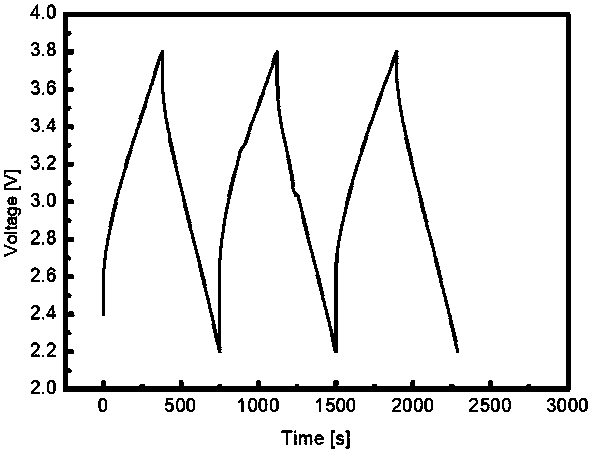

[0036] The making of positive electrode sheet: activated carbon, Li 2 NiO 2, SP, and PVDF are proportioned according to the mass ratio of 80%: 10%: 5%: 5%. PVDF is first dissolved in NMP to obtain a glue solution with a mass concentration of 10%. After mixing and stirring the above substances, add them slowly while stirring in a vacuum environment NMP, slowly adjust the viscosity and solid content of the slurry to make it suitable for coating, stir for 2 hours to obtain the positive electrode slurry, coat the positive electrode slurry on the aluminum foil current collector with a thickness of 20 μm, and vacuum bake it at 150 ° C for 12 hours to carry out molding Cut to get the positive plate of lithium ion capacitor.

[0037] Production of the negative electrode sheet: mix hard carbon, SP, SBR, and CMC according to the mass ratio of 92%: 3%: 2.5%: 2.5%, use DMF as the solvent to obtain the negative electrode slurry, and apply the negative electrode slurry Coated on a copper ...

Embodiment 3

[0042] The making of positive electrode sheet: activated carbon, Li 2 NiO 2 , SP, and PVDF are proportioned according to the mass ratio of 70%: 20%: 5%: 5%. PVDF is first dissolved in DMA to obtain a glue solution with a mass concentration of 3%. After the above materials are mixed and stirred, they are slowly added while stirring in a vacuum environment DMA, slowly adjust the viscosity and solid content of the slurry to make it suitable for coating, stir for 2 hours to obtain the positive electrode slurry, coat the positive electrode slurry on the aluminum foil current collector with a thickness of 20 μm, and vacuum bake at 150°C for 12 hours, then mold Cut to get the positive plate of lithium ion capacitor.

[0043] Production of the negative electrode sheet: mix hard carbon, SP, SBR, and CMC according to the mass ratio of 92%: 3%: 2.5%: 2.5%, and use deionized water as the solvent to obtain the negative electrode slurry, and the negative electrode slurry Coated on a coppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com