A nickel-based catalyst additive for the preparation of high-efficiency catalytic direct oxidation of borohydride

A nickel-based catalyst and catalytic boron technology, which is applied in the field of electrochemical applications, can solve the problems of high resistance to charge transfer in electrode reactions, reduced catalytic activity, and increased impedance of electrochemical reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

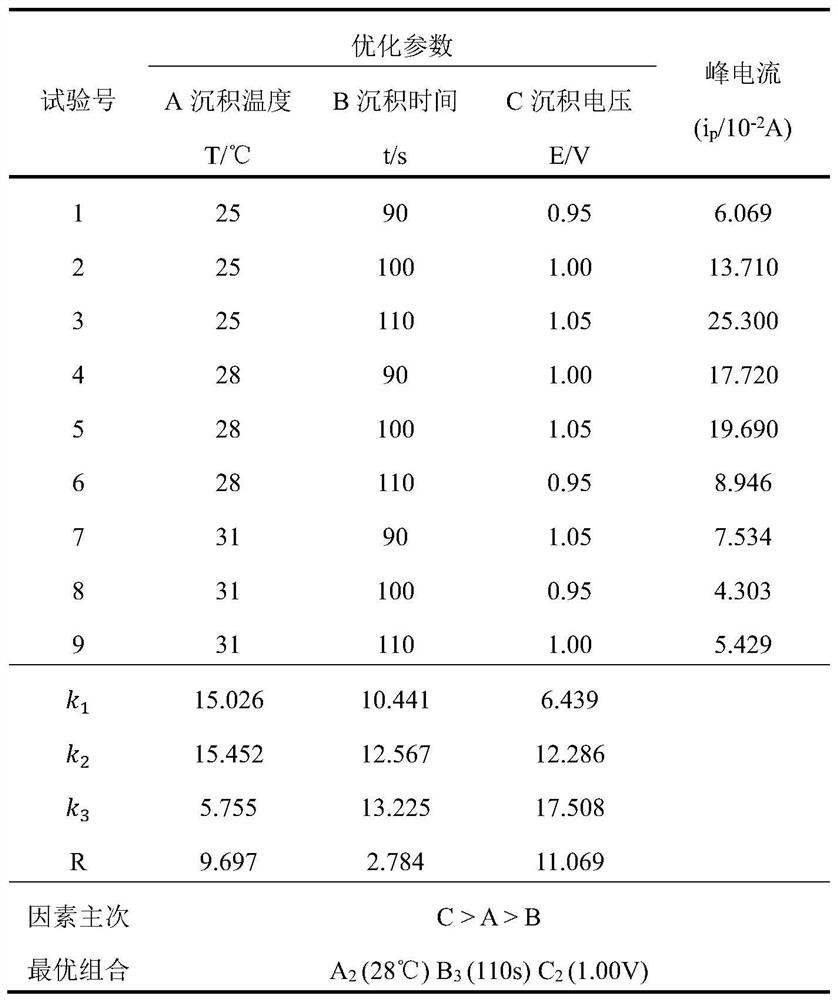

Embodiment 1

[0017] At normal temperature and pressure, prepare 0.2mol / dm 3 NiSO 4 , 0.6g / dm 3 LaCl 3 The solution was used as the electrolyte, and the pH was adjusted to around 3. 2cm 2 A smooth Ni sheet was placed in the above solution as a working electrode for electrodeposition. Determine the optimization parameters as deposition temperature, deposition time and deposition voltage, the number of levels is three, and the specific values are 298.15K, 301.15K, 304.15K; 90s, 100s, 110s; -0.95V, -1.0V, -1.05V, Therefore, three factors and three levels of orthogonal experiments were carried out to prepare Ni-based catalysts under different conditions. Weigh an appropriate amount of sodium borohydride (NaBH 4 ), and dissolve it in 2mol / dm 3 In the sodium hydroxide NaOH solution, make 0.27mol / dm 3 NaBH 4 Solution, mixed evenly, used as electrolyte solution for direct sodium borohydride fuel cell. The Ni-based catalyst prepared under the above different parameter levels was used as ...

Embodiment 2

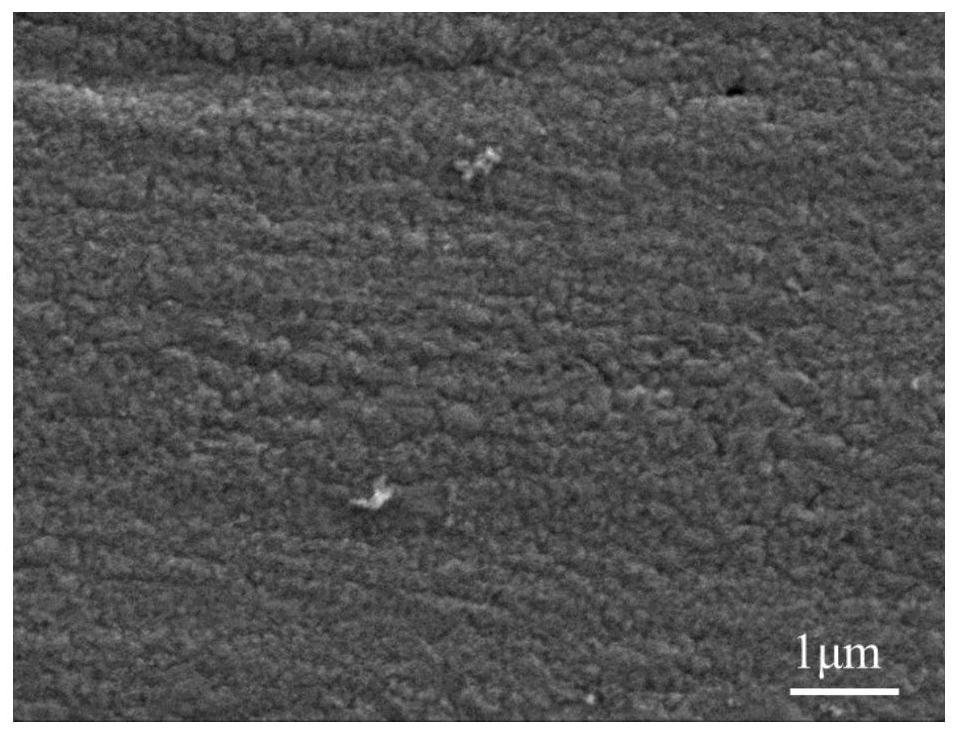

[0021] Under normal temperature and pressure, prepare and add 0.0, 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, 0.9, 1.0g / dm 3 LaCl 3 0.2mol / dm 3 NiSO 4 Solution 100mL, and adjust the pH value to about 3. 2cm 2 The smooth Ni sheet is placed in the above solution as the working electrode, in a constant temperature water bath at 301.15K, with a carbon rod as the counter electrode and a calomel electrode as the reference electrode, Ni is deposited on the metal nickel sheet by the constant potential method to make a A nickel-based catalyst; wherein, the deposition potential used in the process of preparing the nickel-based catalyst is -1.0V, and the deposition time is 110s. Weigh an appropriate amount of NaBH 4 , and dissolve it at 2mol / dm 3 In NaOH solution, make 0.27mol / dm 3 NaBH 4 solution, mixed well as direct NaBH 4 Electrolyte for fuel cells. Different Ni catalysts prepared under the above conditions were used as working electrodes, carbon rods were used as counter elec...

Embodiment 3

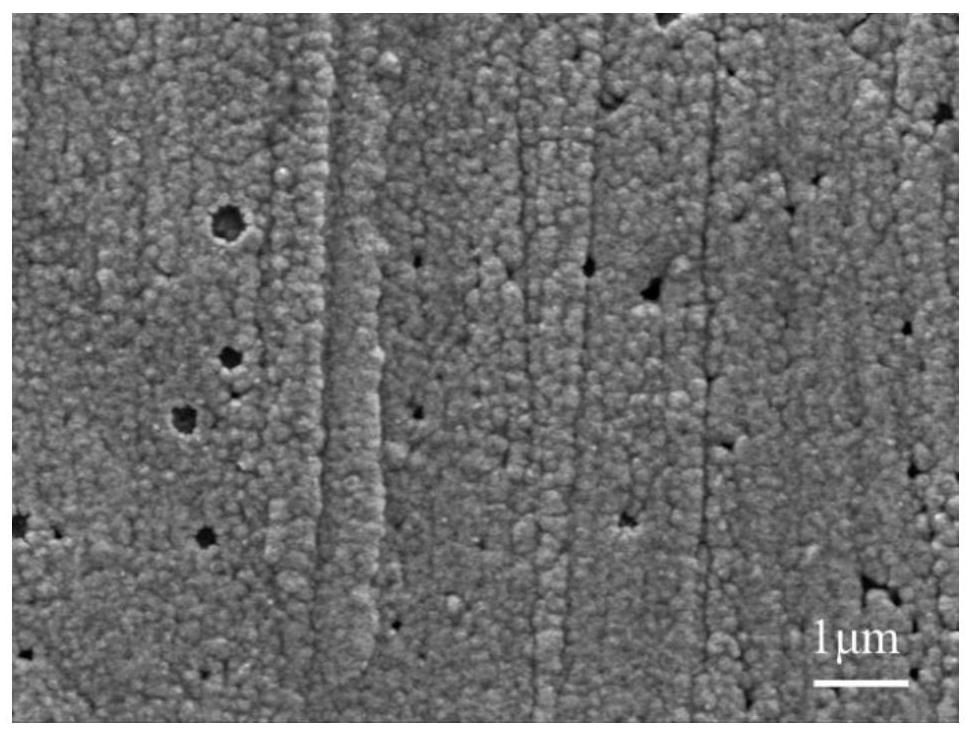

[0027] Under normal temperature and pressure, prepare and add 0.0, 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, 0.8, 0.9, 1.0g / dm 3 LaCl 3 0.2mol / dm 3 NiSO 4 Solution 100mL, and adjust the pH value to about 3. 2cm 2 The smooth Ni sheet is placed in the above solution as the working electrode. At the temperature of the water bath of 301.15K, the carbon rod is used as the counter electrode and the calomel electrode is used as the reference electrode. Ni is deposited on the metal nickel sheet by the constant potential method. A nickel-based catalyst; wherein, the deposition potential used in the process of preparing the nickel-based catalyst is -1.0V, and the deposition time is 110s. Weigh an appropriate amount of NaBH 4 , and dissolve it at 2mol / dm 3 In NaOH solution, make 0.27mol / dm 3 NaBH 4 Solution, mixed evenly, used as electrolyte solution for direct sodium borohydride fuel cell. Different Ni-based catalysts prepared under the above conditions were used as working electrodes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com