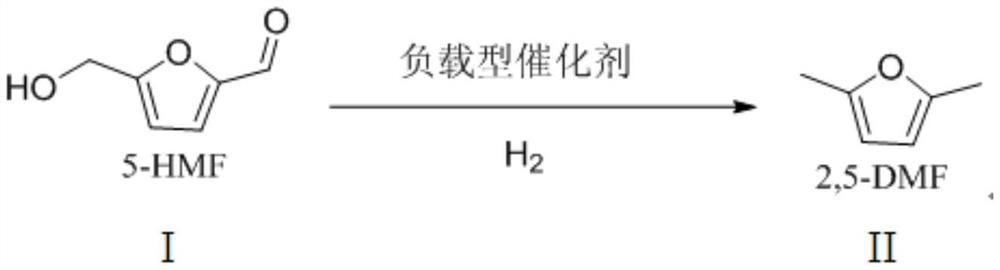

Method for preparing 2,5-dimethylfuran through catalytic hydrogenation of 5-hydroxymethylfurfural

A technology of hydroxymethylfurfural and dimethylfuran, which is applied in the field of catalytic hydrogenation of 5-hydroxymethylfurfural to prepare 2,5-dimethylfuran, can solve the problem of high metal loading of tungsten carbide, large amount of catalyst, pressure Large and other problems, to achieve the effect of large active specific surface area, good selectivity, and small dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of supported bifunctional catalyst of the present invention, with 3wt% Ni-MnO x / C catalyst (the ratio of Ni and Mn is 3:1) as an example: Ni-MnO prepared by co-impregnation method x / MC (mesoporous carbon) catalyst was prepared as follows: weigh 1 g of 200-mesh mesoporous carbon, place it in a crucible, and bake it at 400° C. for 5 hours. Weigh 0.1115g Ni(NO 3 ) 2 ·6H 2 O is placed in another crucible, add 0.7g deionized water, dissolve completely, weigh 0.0335g C 4 h 6 MnO 4 4H 2 O was added to the nickel nitrate solution to fully mix the nickel nitrate and manganese acetate, ultrasonically dissolve it fully, add mesoporous carbon, stir while adding, impregnate at room temperature for 24 hours, dry at 110°C for 12 hours, 500°C in hydrogen Reduction under atmosphere for 3 hours yielded Ni-MnO with a total metal loading of 3 wt%. x / MC catalyst;

[0041] Preparation of Ni-MnO by Step-wise Impregnation Method x The / AC catalyst was prepar...

Embodiment 1

[0045] Take 0.126g (2mmol) 5-hydroxymethylfurfural in a beaker, add 6mL tetrahydrofuran to dissolve, add the solution to a 25mL autoclave, add 0.252g Ni-MnO with a loading capacity of 3wt% x / AC catalyst (the ratio of the amount of Ni and Mn is 3:1, and the catalyst is prepared by the co-impregnation method), and nitrogen is purged five times, the reaction temperature is 180 ° C, the hydrogen pressure is 2.0 MPa, and the reaction is 3 hours. 2,5-Dimethylfuran was obtained, and the catalytic conversion frequency (TOF) was 50.7h -1 , the yield is 96.7%;

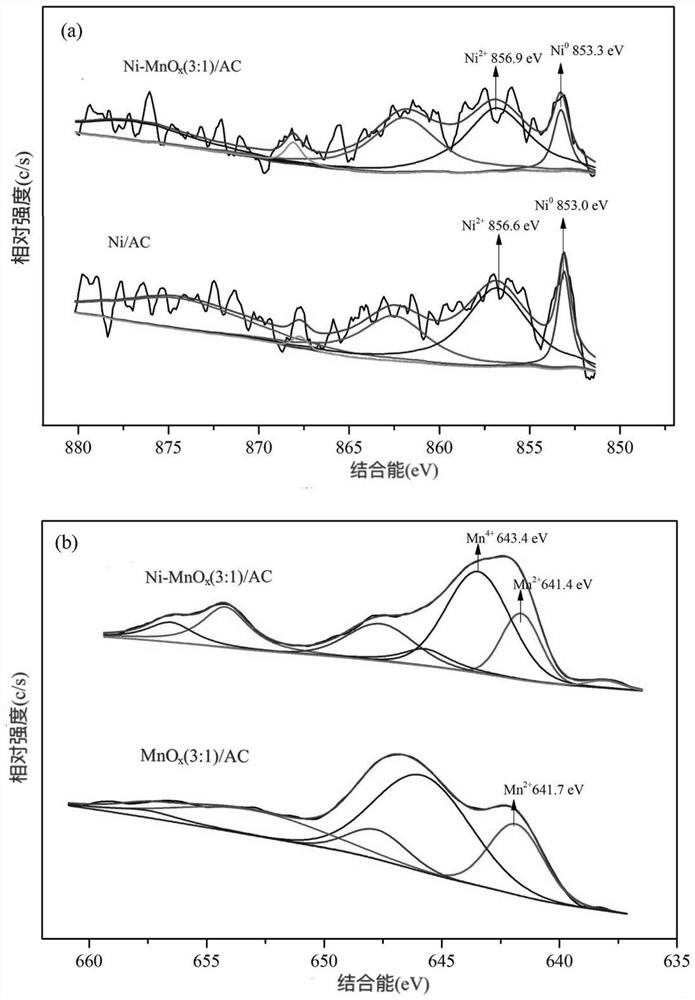

[0046] From figure 1 (a), it can be seen that Ni-MnO x / AC Catalyst Ni 2p 3 / 2 It can be divided into two peaks, the corresponding electron binding energy is 853.3eV and 856.9eV, respectively attributed to Ni 0 and Ni 2+ . While the Ni 2p of the Ni / AC catalyst 3 / 2 Belongs to Ni 0 and Ni 2 + The electron binding energies corresponding to the two peaks are 853.0eV and 856.6eV, respectively. Ni 2p on the surface of suppo...

Embodiment 2

[0049] Take 0.1260g (1mmol) of 5-hydroxymethylfurfural in a beaker, add 6mL of tetrahydrofuran to dissolve, add the solution to a 25mL autoclave, and add 0.025g of Ni-MnO with a loading capacity of 3wt%. x / AC catalyst (the ratio of the amount of Ni and Mn is 3:1, the catalyst is prepared by the distribution impregnation method and the impregnation sequence is first impregnated with Ni and then impregnated with Mn), and nitrogen is purged five times, the reaction temperature is 180 °C, and the hydrogen pressure is 2.0MPa, reacted for 3 hours, produced 2,5-dimethylfuran, and the catalytic conversion frequency (TOF) was 52.9h -1 , the yield was 97.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com