Electrochemical in-situ graphene synthesis-based modification method for carbon-based electrode

An electrochemical and graphene technology, which is applied in the field of carbon-based electrode modification based on electrochemical in-situ graphene synthesis, can solve the problems of the modification method, such as electrode shape, component limitation, pollution stability repeatability, and cumbersome process. Obtain the effect of electrochemical catalytic activity, low equipment requirements, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1—The preparation of in-situ graphene-modified carbon paste electrodes

[0035]The carbon paste electrode (made by fully mixing graphite powder and paraffin with a mass ratio of 7:3 and then filling it into a hard plastic tube with an inner diameter of 3mm and then performing simple surface polishing) was used as the working electrode, and the platinum sheet electrode was used as the counter electrode. The Ag / AgCl electrode was used as the reference electrode to form a three-electrode system, and 0.1 M phosphate buffered saline (PBS) at pH 7.0 was used as the supporting electrolyte solution.

[0036] Immerse the three-electrode working surface under the surface of the supporting electrolyte solution, apply a working voltage of 0-2.5V to the electrode system through cyclic voltammetry scanning, the scanning rate is 100mV / s, scan for 5 cycles, take out the working electrode and fully wet it with deionized water. After washing and drying, it will be used as a graph...

Embodiment 2

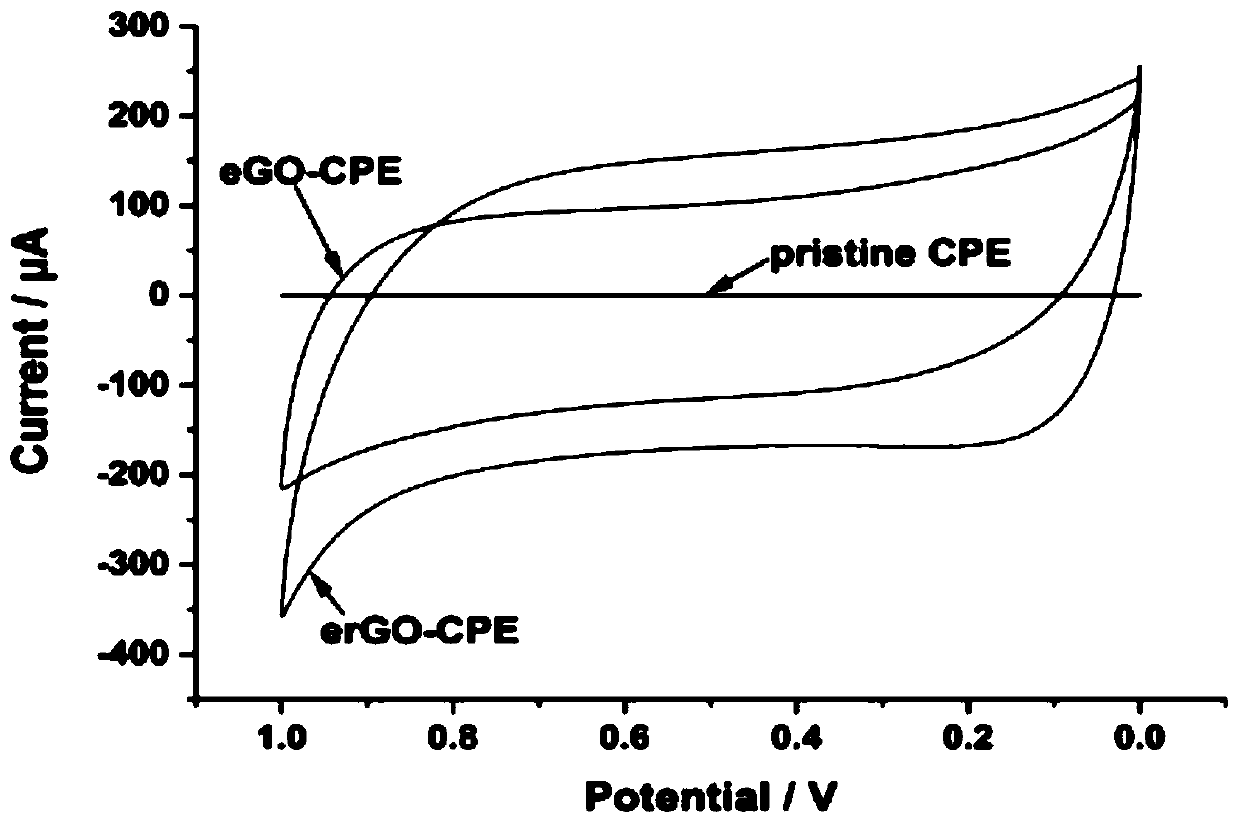

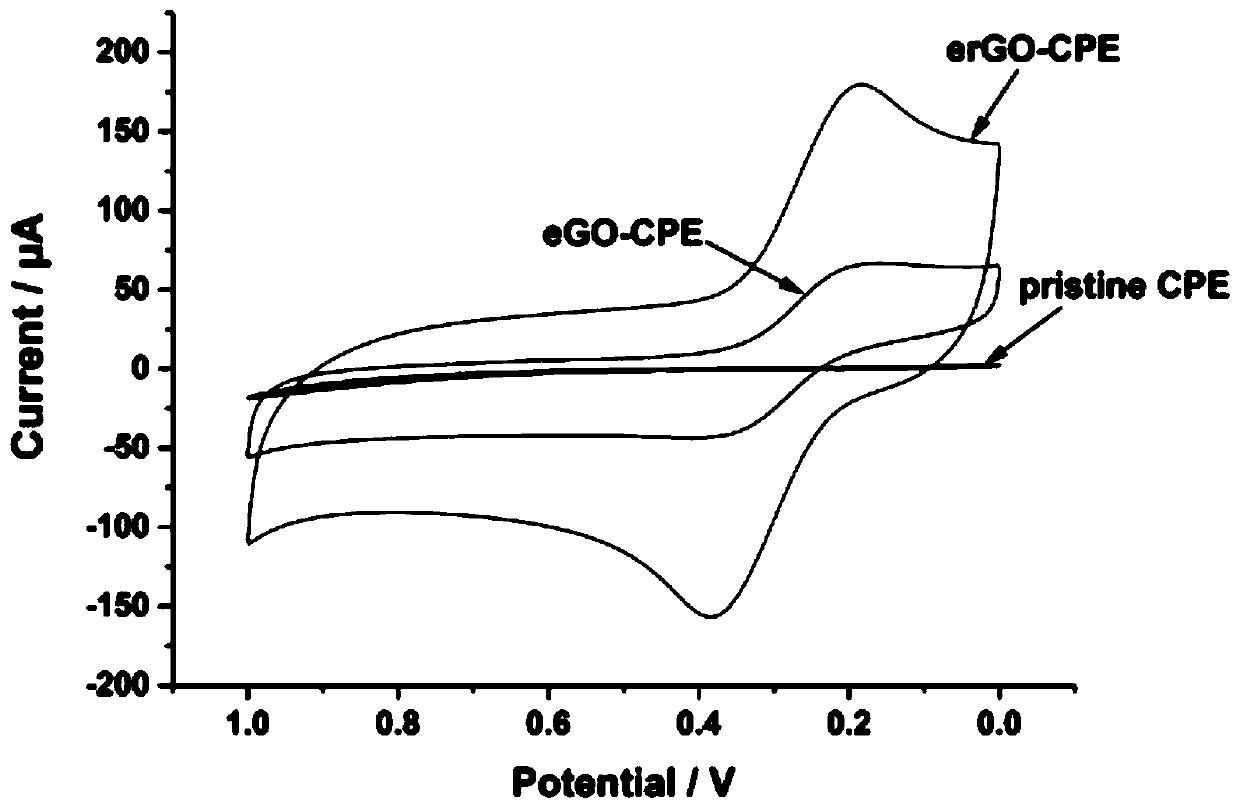

[0041] Example 2—In situ graphene-modified carbon paste electrode improves sensing performance of oxidase electrode

[0042] Using the electrode described in Example 1 as a system, 10 times of 0-2.5V cyclic voltammetry scanning at a scan rate of 100mV / s was performed in 0.1M PBS at pH 6.0 to conduct electrochemical oxidation treatment, and the working electrode was taken out to deionize. The water was fully rinsed and dried as a graphene oxide functionalized electrode (eGO-CPE). The electrode was immersed in the buffer system again, and cyclic voltammetry scanning at -1.5~0V was performed for 5 times, and the scanning rate was 100mV / s for electrochemical reduction treatment. The working electrode was taken out and fully rinsed with deionized water to dry as the function of reducing graphene oxide. Electrode (erGO-CPE).

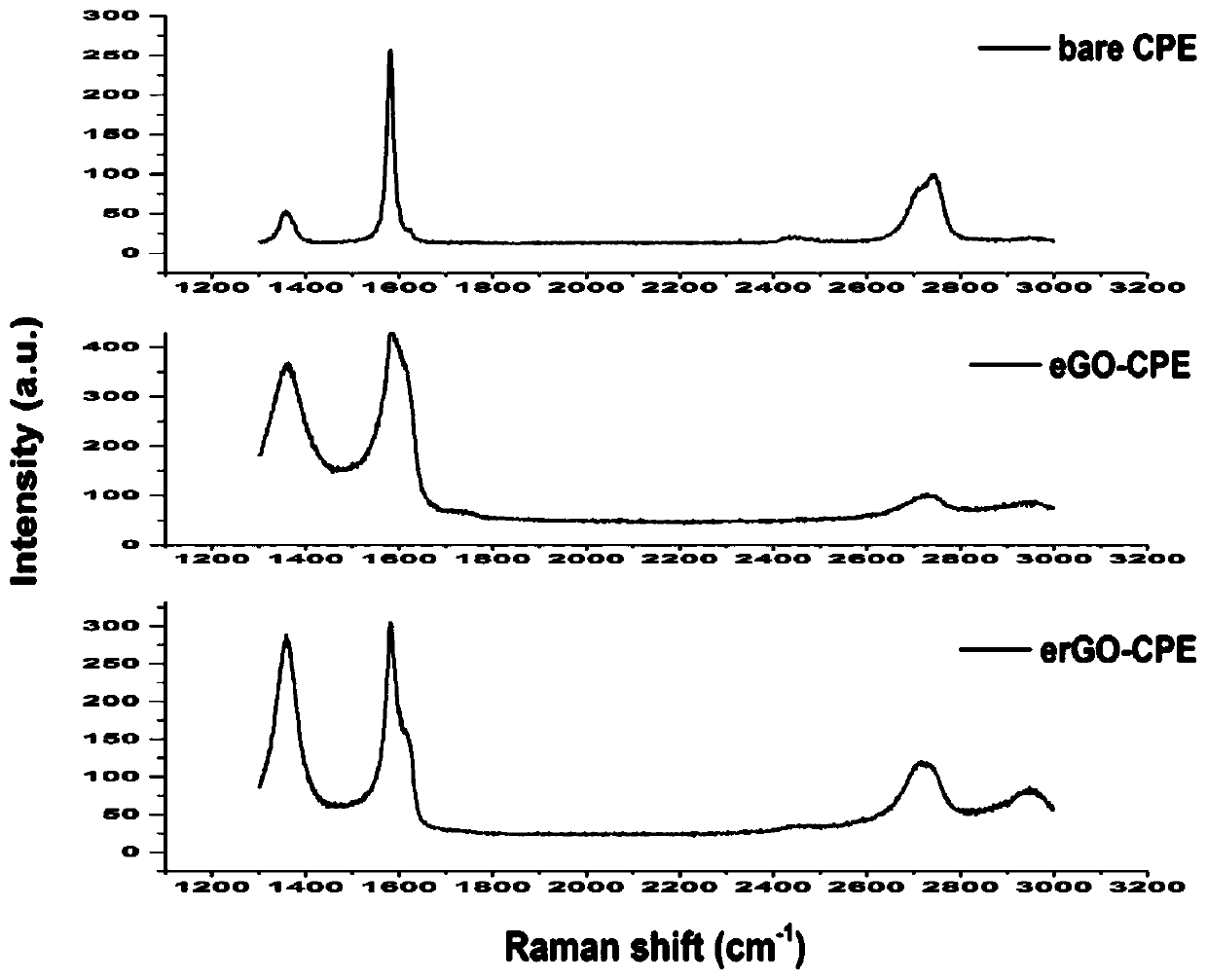

[0043] The CPE, eGO-CPE and erGO-CPE were taken for in-situ SEM characterization, and the results are as follows Figure 4 , from left to right represent th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com