A kind of composite fiber for artificial anterior cruciate ligament and its preparation method and application

A technology of anterior cruciate ligament and composite fiber, which is applied in the field of composite fiber of artificial anterior cruciate ligament and its preparation, can solve the problems of insufficient ligament strength, poor cell affinity, and low wear resistance, and achieve strong cell affinity , Good tissue compatibility and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Weigh polyhydroxybutyrate (purchased from Dongguan Suzhan Plastic Co., Ltd., with a number average molecular weight of 1.9×10 5 ) and polyglycolic acid (purchased from Shenzhen Boli Biomaterials Co., Ltd., with a number average molecular weight of 55,000), vacuum-dried at 50°C for 12 hours, and set aside.

[0039] (2) Add the polyhydroxyhexyl butyrate and polyglycolic acid dried in step (1) into deionized water at a mass ratio of 1:1, and heat to 80°C for 3 hours at a stirring speed of 500r / min , fully dissolved, and then filtered under reduced pressure, defoaming at 70° C. for 1 h in a vacuum state to obtain a mixed solution with a total solute concentration of 2 wt.%, which is ready for use.

[0040] (3) adopt dry spinning technology, the mixed solution in the step (2) is extruded solution trickle from spinneret capillary hole and enters spinning tunnel, passes through the hot air in the tunnel (the mixed gas of air and steam, The flow rate ratio of the two is 1:...

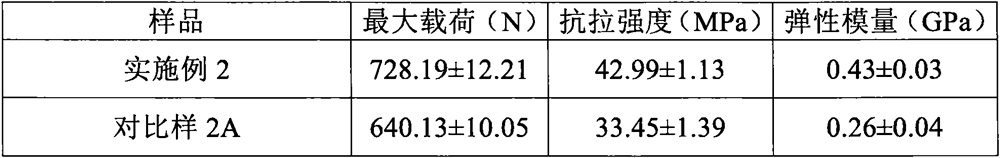

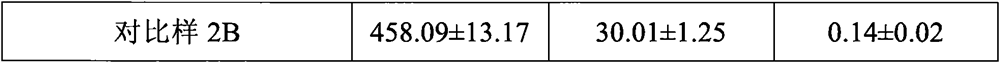

Embodiment 2

[0043] (1) Weigh polyhydroxybutyrate (purchased from Dongguan Suzhan Plastic Co., Ltd., with a number average molecular weight of 2.0×10 5 ) and polyglycolic acid (purchased from Shenzhen Boli Biomaterials Co., Ltd., with a number average molecular weight of 58,000), vacuum-dried at 50°C for 18 hours, and set aside.

[0044] (2) Add polyhydroxybutyrate and polyglycolic acid dried in step (1) to absolute ethanol at a mass ratio of 1:2, and heat to 85°C under reflux at a stirring speed of 550r / min 4h, fully dissolved, then vacuum filtration, degassing at 75°C for 1h in a vacuum state, to obtain a mixed solution with a total solute concentration of 3wt.%, ready for use.

[0045] (3) adopt dry spinning technology, the mixed solution in the step (2) is extruded solution trickle from spinneret capillary hole and enters spinning tunnel, passes through the hot air in the tunnel (the mixed gas of air and water vapor, The flow rate ratio of the two is 1:10), so that the solvent in the ...

Embodiment 3

[0048] (1) Weigh polyhydroxybutyrate (purchased from Dongguan Suzhan Plastic Co., Ltd., with a number average molecular weight of 2.1×10 5 ) and polyglycolic acid (purchased from Shenzhen Boli Biomaterials Co., Ltd., with a number-average molecular weight of 61,000), vacuum-dried at 50°C for 24 hours, and set aside.

[0049] (2) Add polyhydroxybutyrate and polyglycolic acid after drying in step (1) to dimethylacetamide at a mass ratio of 1:3, and heat to 85 at a stirring speed of 600r / min. Reflux at ℃ for 6 hours to fully dissolve, then filter under reduced pressure, defoam at 75℃ for 1.5 hours under vacuum to obtain a mixed solution with a total solute concentration of 4wt.%, which is ready for use.

[0050] (3) adopt dry spinning technology, the mixed solution in the step (2) is extruded solution trickle from spinneret capillary hole and enters spinning tunnel, passes through the hot air in the tunnel (the mixed gas of air and water vapor, The flow rate ratio of the two is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com