Device and process for removing and recovering SO2 in industrial exhaust gas or tail gas

An industrial flue gas and heat recovery device technology, applied in the field of flue gas tail gas treatment, can solve the problems of low heat energy recovery efficiency, increased energy consumption, large amount of absorption liquid, etc., to achieve enhanced heat transfer, reduced usage, and reduced energy consumption small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

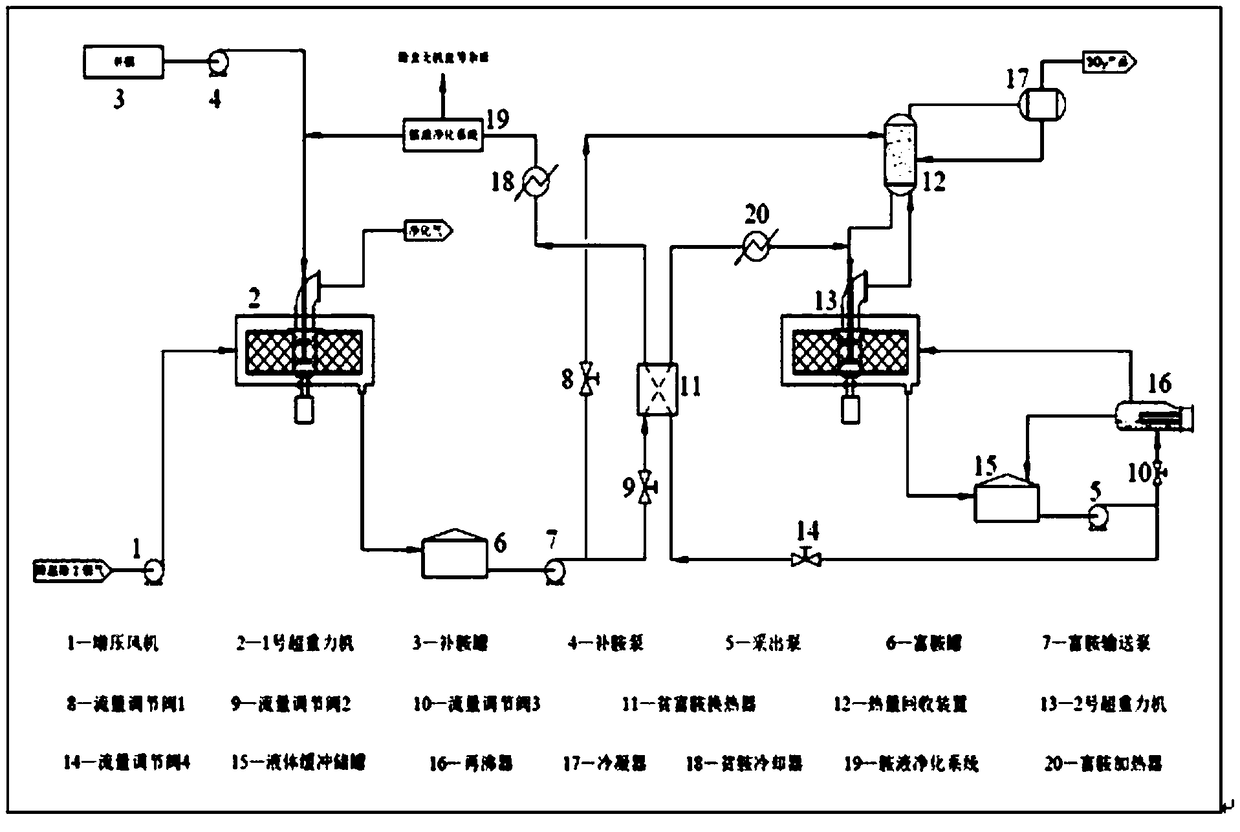

Method used

Image

Examples

Embodiment 1

[0040] Use the above device and process to remove and recover sulfur dioxide in flue gas. Among them, the temperature of the No. 1 supergravity machine is controlled at 30-35℃, the supergravity level is 120, and the volume flow ratio of the rich amine liquid heated by the hot lean amine liquid and the rich amine liquid heated by the hot steam is 10:1-8:1. The regeneration temperature in the No. 2 supergravity machine is controlled at 105°C, the supergravity level is 150, the temperature of the reboiler is controlled at 120-130°C, the temperature of the condenser is controlled at 10-20°C, the amine liquid after the lean amine cooler The temperature is controlled at 30-35℃, and the volume flow ratio of the extracted liquid and the liquid flowing to the reboiler is 10:1-15:1.

[0041] Sampling and analysis at the gas outlet of No. 1 supergravity machine, SO 2 The concentration is 80mg / m 3 , Sampling and analysis at the gas outlet of the condenser, SO 2 The gas purity can reach 99.5%...

Embodiment 2

[0043] As described in Example 1, with other conditions unchanged, the temperature of the No. 1 supergravity machine was adjusted to 25-30°C. Sampling and analysis at the gas outlet of No. 1 supergravity machine, SO 2 The concentration is 80mg / m 3 , Sampling and analysis at the gas outlet of the condenser, SO 2 The gas purity can reach 99.5%.

Embodiment 3

[0045] As described in Example 1, with other conditions unchanged, the supergravity level of the No. 1 supergravity machine was adjusted to 200. Sampling and analysis at the gas outlet of No. 1 supergravity machine, SO 2 The concentration is 50mg / m 3 , Sampling and analysis at the gas outlet of the condenser, SO 2 The gas purity can reach 99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com