A kind of preparation method and device of nanoscale dispersion liquid

A dispersion liquid and nano-scale technology, which is applied in mixing methods, chemical instruments and methods, transportation and packaging, etc., can solve the problems of limited preparation volume, discontinuous preparation process, and increased particle size of nanoparticles, so as to avoid excessive dilution, Realize the effect of mass production and particle size improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

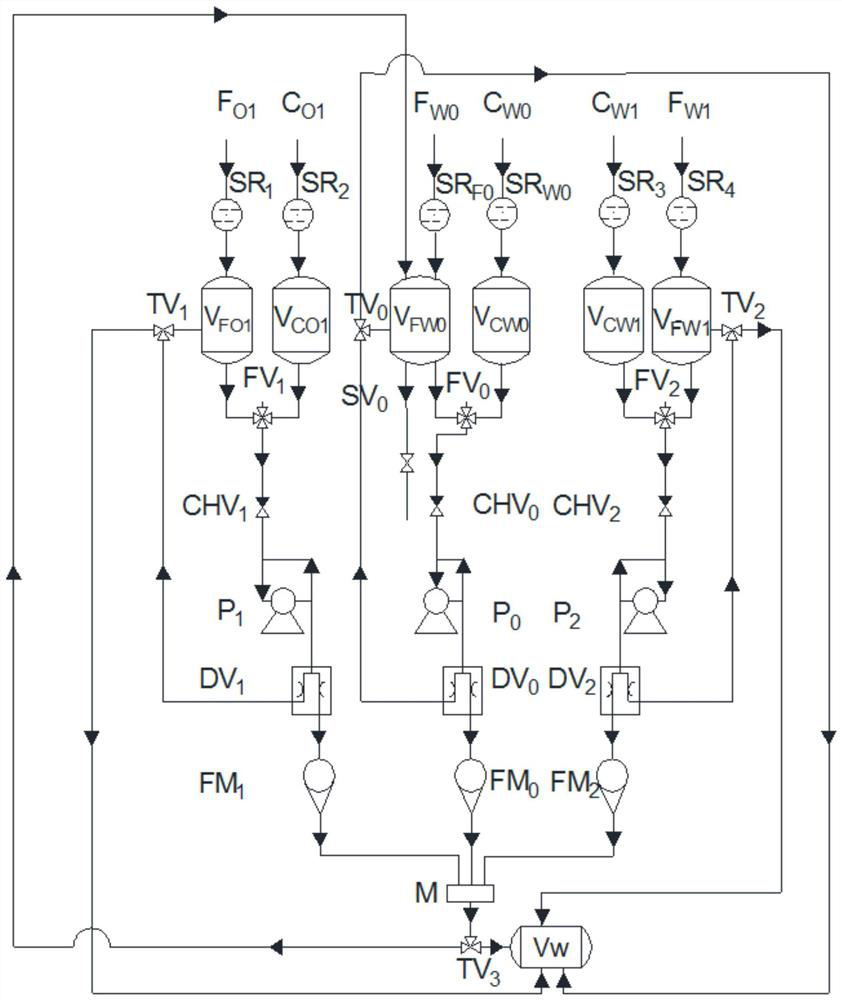

[0049] Such as figure 1 As shown, the nano-dispersion preparation device is equipped with a CIJ-L mixer with three inlets. The parts and operations in the device are represented by English letter codes, and the same parts are distinguished by numerical subscripts:

[0050] f O1 : organic phase solution,

[0051] f W0 , F W1 : aqueous solution,

[0052] C O1 :Organic solvents,

[0053] C W0 、C W1 :water,

[0054] V FO1 : organic phase storage tank,

[0055] V FW0 : circulating storage tank,

[0056] V FW1 : aqueous phase storage tank,

[0057] V CO1 : Organic solvent cleaning storage tank,

[0058] V CW0 , V CW1 : water cleaning storage tank,

[0059] V W : waste liquid storage tank,

[0060] SR 1 、SR 2 、SR 3 、SR 4 、SR F0 、SR W0 :Filter,

[0061] TV 0 、TV 1 、TV 2 、TV 3 :Three-way valve,

[0062] FV 0 、FV 1 、FV 2 :Four-way valve,

[0063] CHV 0 、CHV 1 、CHV 2 : check valve,

[0064] SV 0 :Shut-off valve,

[0065] P 0 ,P 1 ,P 2 :Pump, ...

Embodiment 2

[0080] Such as Figure 4 As shown, the nano-dispersion preparation device is equipped with a five-inlet CMIJ-L mixer. The parts and operations in the device are represented by English letter codes, and the same parts are distinguished by numerical subscripts:

[0081] f O1 , F O2 : organic phase solution,

[0082] f W0 , F W1 , F W2 : aqueous solution,

[0083] C O1 、C O2 :Organic solvents,

[0084] C W0 、C W1 、C W2 :water,

[0085] V FO1 , V FO2 : organic phase storage tank,

[0086] V FW0 : circulating storage tank,

[0087] V FW1 , V FW2 : aqueous phase storage tank,

[0088] V CO1 , V CO2 : Organic solvent cleaning storage tank,

[0089] V CW0 , V CW1 , V CW2 :: water cleaning tank,

[0090] V W : waste liquid storage tank,

[0091] SR 1 、SR 2 、SR 3 、SR 4 、SR 5 、SR 6 、SR 7 、SR 8 、SR F0 、SR C0 :Filter,

[0092] TV 0 、TV 1 、TV 2 、TV 3 、TV 4 、TV 5 :Three-way valve,

[0093] FV 0 、FV 1 、FV 2 、FV 3 、FV 4 :Four-way valve,

[0...

Embodiment 3

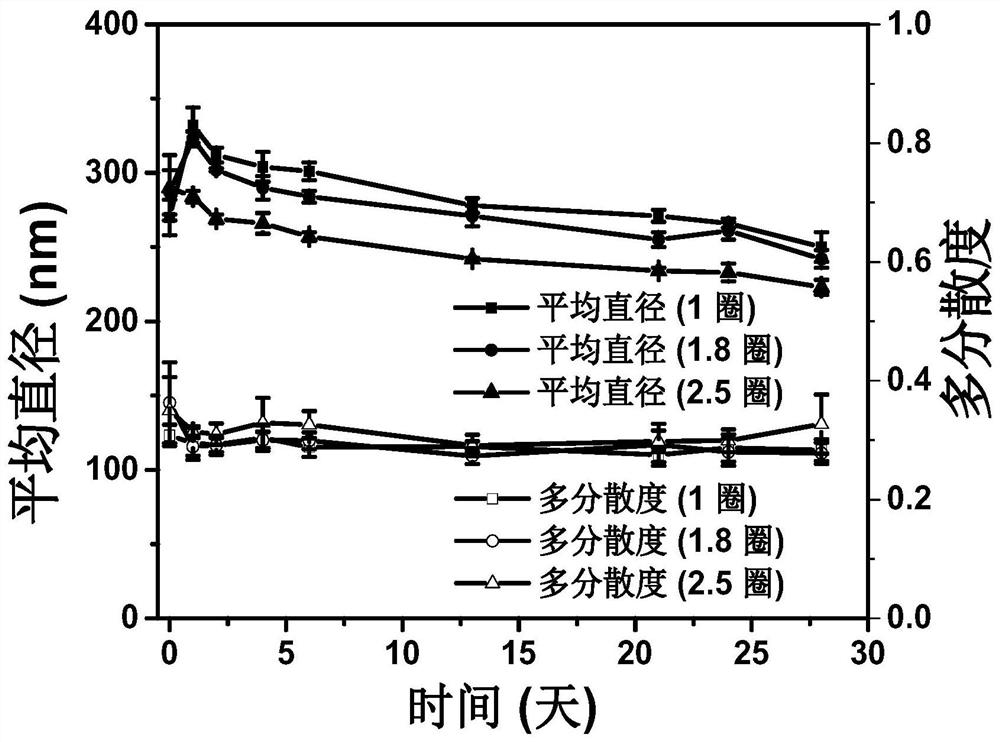

[0105] Prepare 150 mL of ethanol solution containing liquid tangerine essential oil (ACDlogP=4.4) (33uL / mL) and Tween 80 (67uL / mL) at room temperature, and place it in the organic phase storage tank V FO1 ; 150mL water is placed in the water storage tank V FW1 , 400mL water is placed in the circulation storage tank V FW0 Using the same method as in Example 1, after turning on the power supply and running the pump to exhaust the air, ethanol solution, water, and circulating fluid are simultaneously pumped into each feed port of the CIJ-L mixer with a flow ratio of 1:1:8. When the liquid circulates in the circulating storage tank for 100, 200, and 300 seconds (corresponding to 1, 1.8, and 2.5 cycles respectively, and obtains 3.3, 5.6, and 7.1 μg / mL tangerine essential oil nanoemulsion), take a few samples each and use dynamic light scattering tracking to measure the dispersion. The liquid particle size is 1 week, and the preparation is completed after a cycle of 300 seconds. O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com