Air-stable nano zero-valent iron as well as preparation method and application thereof

A nano-zero-valent iron, stable technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of expensive coating materials, toxic substance pollution, complicated preparation methods, etc., and achieve the reduction of preparation costs and the method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A preparation method of air-stable nanometer zero-valent iron, comprising the following steps:

[0038] (1) Precursor preparation: crushing and screening goethite, limonite or hematite;

[0039] (2) Preparation of nanometer zero-valent iron: the above-mentioned goethite, limonite or hematite powder is packed into a quartz tube, placed in a reduction furnace, and hydrogen is introduced into the reduction furnace as a reducing agent until the gas is released. Condensed water no longer appears, and nanometer zero-valent iron is obtained after cooling under protective gas;

[0040] (3) Passing air into the quartz tube to slowly oxidize the above-mentioned nanometer zero-valent iron, and then obtain "shell-core" nanometer zero-valent iron stable in air.

[0041] Further, in step (2), the dosage of goethite powder is 10 g, and the temperature of the reduction furnace is 550-600° C. Lower temperature will result in incomplete reduction of iron oxide, and higher temperature w...

Embodiment 1

[0045] A preparation method of air-stable nanometer zero-valent iron comprises the following steps:

[0046] (1) Precursor preparation:

[0047] The goethite is crushed and sieved to obtain particles with a particle size of 0.1-0.2 mm.

[0048] (2) Preparation of nanometer zero-valent iron

[0049] Put 10g of the above-mentioned goethite powder into a quartz tube, place it in a reduction furnace at a temperature of 600°C, and feed 100mL / min hydrogen into the reduction furnace as a reducing agent until no condensed water appears in the outlet gas. After cooling, nanometer zero-valent iron is obtained.

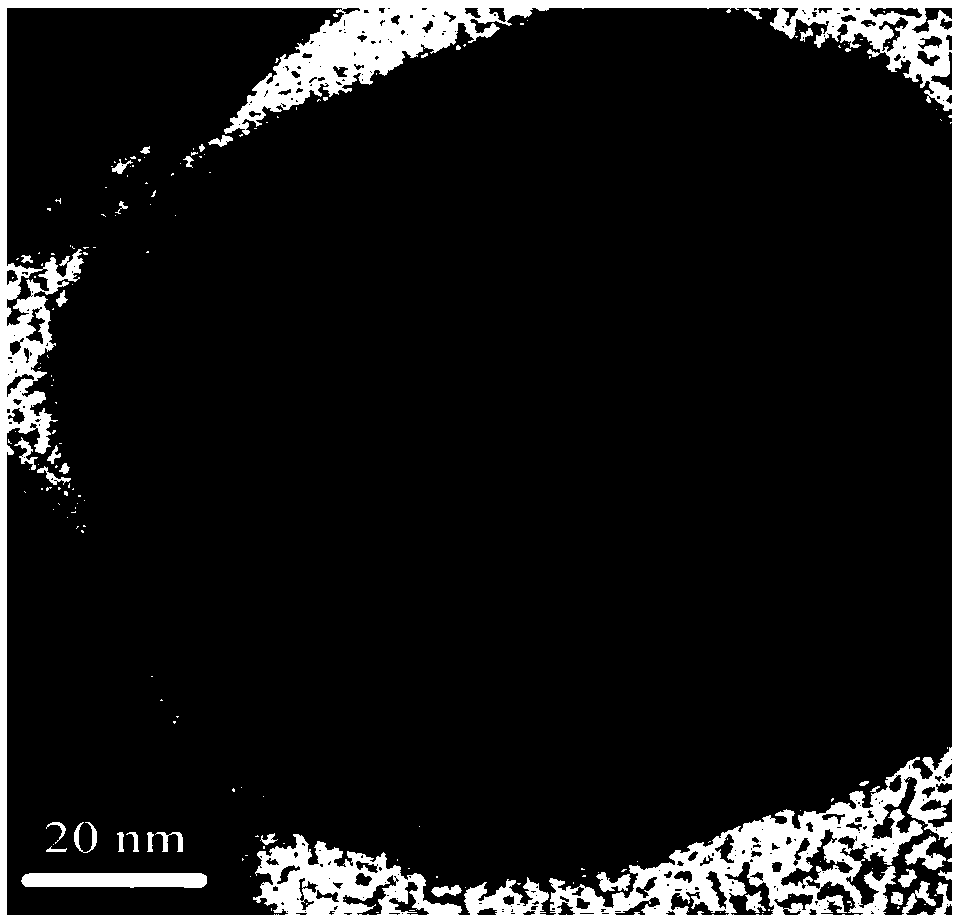

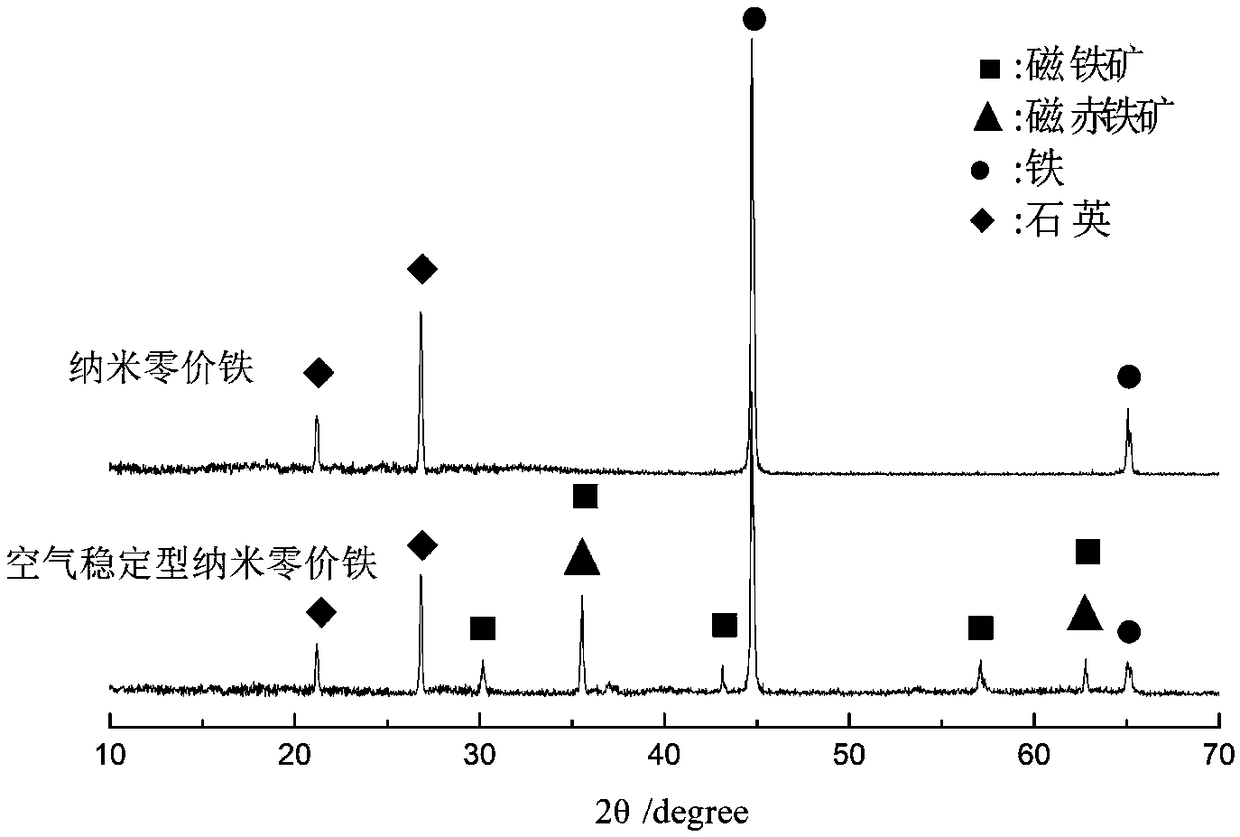

[0050] (3) Pass air at 8mL / min into the quartz tube to slowly oxidize the above-mentioned nano-zero-valent iron. After 24 hours, a "shell-core" nano-zero-valent iron stable in air is obtained, with a 5nm iron oxide layer on the surface. The transmission electron microscope image of the air-stable nano-zero-valent iron prepared in this example is as follows: figure 1 As shown...

Embodiment 2

[0052] When preparing nanometer zero-valent iron, the precursor can be limonite and hematite instead of goethite, and the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com