Method for preparing CNT-Cu composite powder by solution combustion method

A technology of solution combustion and composite powder, which is applied in the field of preparation of CNT-Cu composite powder by solution combustion method, can solve the problem of difficult large-scale composite of carbon nanotubes and metals, achieve low cost, simple method and process, and improve bonding strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

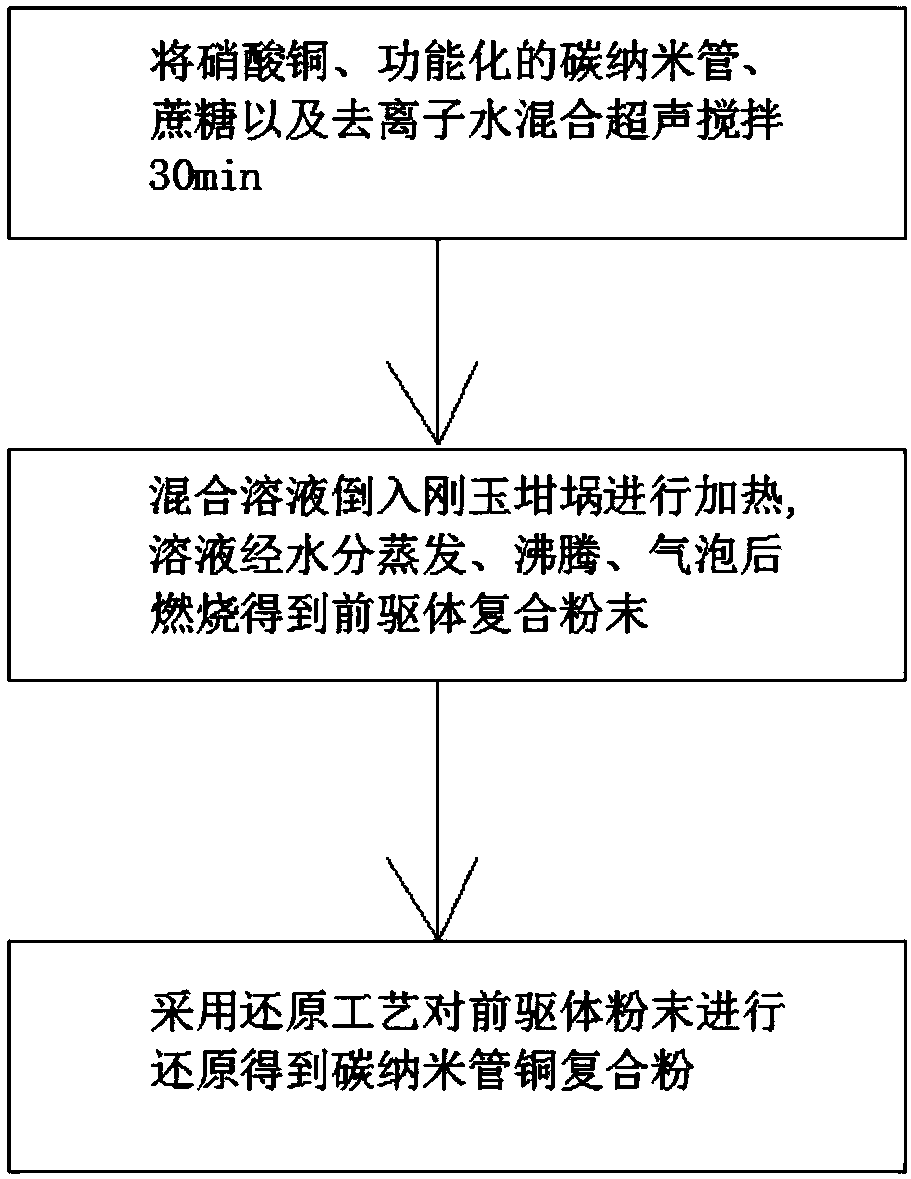

[0033] Such as figure 1 As shown, the present application provides a method for preparing CNT-Cu composite powder by solution combustion method, a method for preparing CNT-Cu composite powder by solution combustion method, which is characterized in that it comprises the following steps:

[0034] (1) Copper nitrate, functionalized carbon nanotubes, sucrose and deionized water were mixed and ultrasonically stirred for 25 minutes, so that each component was mixed evenly to obtain a mixed solution;

[0035] (2) Pour the mixed solution in step (1) into a corundum crucible for heating, and the solution is evaporated, boiled, and bubbled to obtain a precursor composite powder;

[0036] (3) Using the reduction process in the aqueous solution powder mixing method to reduce the precursor powder obtained by burning the solution in step (2) to obtain carbon nanotube copper composite powder. The process principle of the present invention is to use the exothermic properties of the mixture ...

specific Embodiment 2

[0049] Such as figure 1 As shown, the present application provides a method for preparing CNT-Cu composite powder by solution combustion method, a method for preparing CNT-Cu composite powder by solution combustion method, which is characterized in that it comprises the following steps:

[0050] (1) Copper nitrate, functionalized carbon nanotubes, sucrose and deionized water were mixed and ultrasonically stirred for 30 minutes, so that the components were evenly mixed to obtain a mixed solution;

[0051] (2) Pour the mixed solution in step (1) into a corundum crucible for heating, and the solution is evaporated, boiled, and bubbled to obtain a precursor composite powder;

[0052] (3) Using the reduction process in the aqueous solution powder mixing method to reduce the precursor powder obtained by burning the solution in step (2) to obtain carbon nanotube copper composite powder. The process principle of the present invention is to use the exothermic properties of the mixture...

specific Embodiment 3

[0065] Such as figure 1 As shown, the present application provides a method for preparing CNT-Cu composite powder by solution combustion method, a method for preparing CNT-Cu composite powder by solution combustion method, which is characterized in that it comprises the following steps:

[0066] (1) Copper nitrate, functionalized carbon nanotubes, sucrose and deionized water were mixed and ultrasonically stirred for 35 minutes, so that the components were evenly mixed to obtain a mixed solution;

[0067] (2) Pour the mixed solution in step (1) into a corundum crucible for heating, and the solution is evaporated, boiled, and bubbled to obtain a precursor composite powder;

[0068] (3) Using the reduction process in the aqueous solution powder mixing method to reduce the precursor powder obtained by burning the solution in step (2) to obtain carbon nanotube copper composite powder. The process principle of the present invention is to use the exothermic properties of the mixture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com