High-performance fiber spacer fabric and resin composite device and method

A high-performance fiber and spacer fabric technology, which is applied in the field of carbon fiber molding technology, can solve the problems of many bubbles, low production efficiency, and poor labor hygiene conditions, and achieve the effects of uniform distribution of resin layers, improved production efficiency, and enhanced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

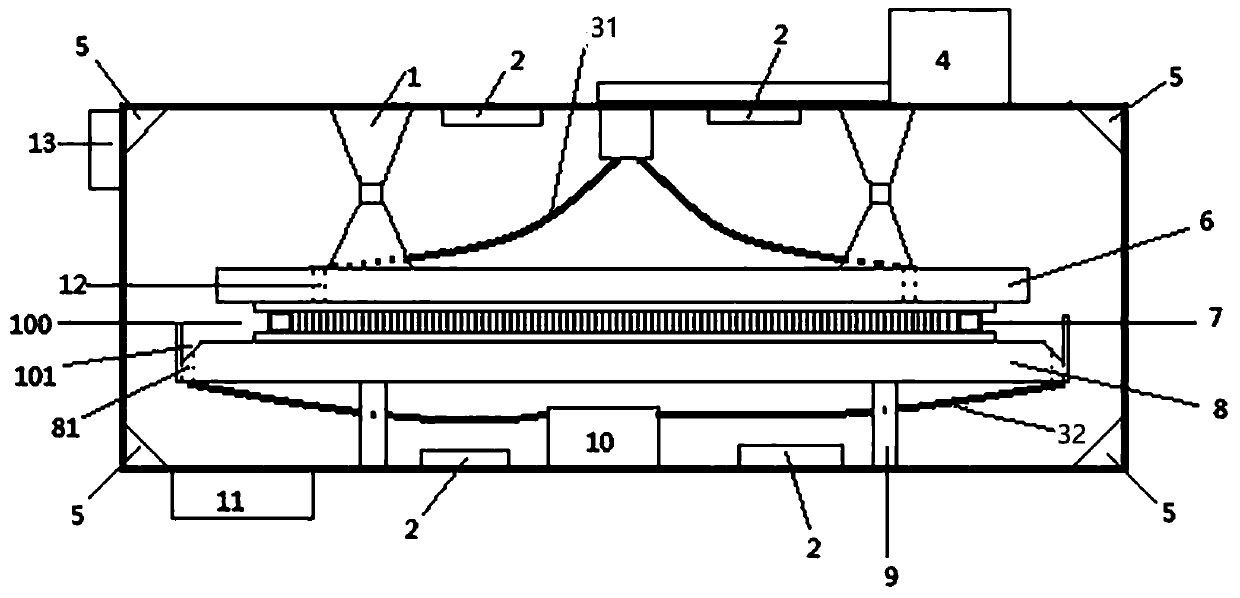

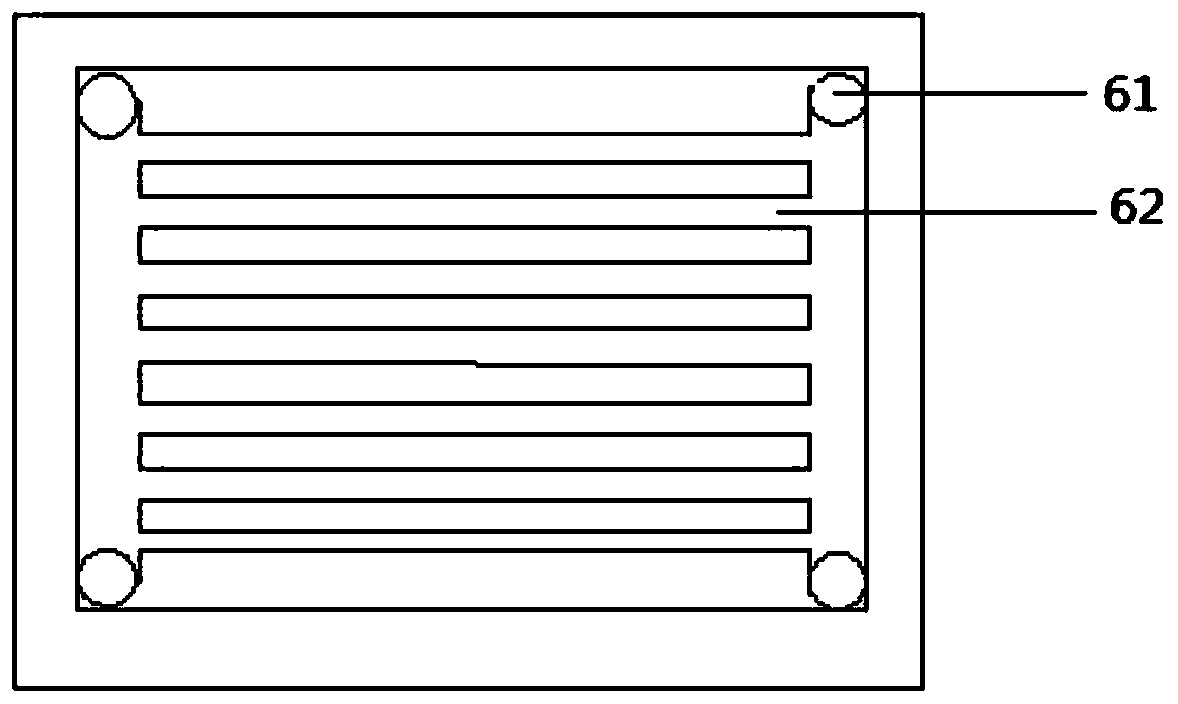

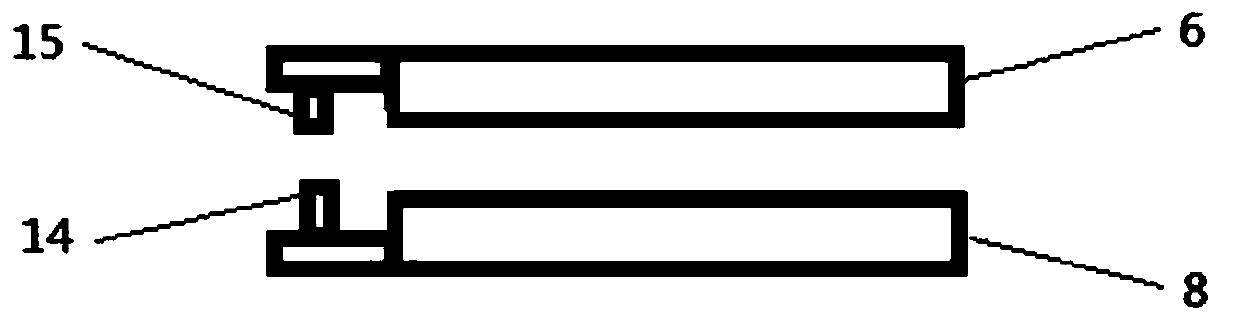

[0067] Embodiment 1, high-performance fiber spacer fabric and resin composite device, such as Figure 1~4 As shown, it includes a box body, a clamping assembly, a heating assembly, a resin casting assembly, a fan system, a control panel 13 and a vacuum-assisted molding system.

[0068] The heating component is located in the inner cavity of the box and is used for heating the inner cavity of the box to accelerate the curing of the resin. The heating assembly includes at least two heaters 2 corresponding up and down, and each heater 2 is electrically connected to a control panel 13 , and the control panel 13 controls the heating temperature of the heaters 2 . In this embodiment, there are four heaters 2 in total, two heaters 2 are fixed on the top of the box cavity, and the remaining two heaters 2 are at the bottom of the box cavity.

[0069] The fan system is located in the inner cavity of the box, which is used to quickly cool down the box and improve production efficiency. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com