A string of red petal-based graphene porous carbon nanosheets and its preparation method and use

A technology of graphene and nanosheets, which is applied in the direction of nano-carbon, hybrid capacitor electrodes, etc., can solve the problems of cumbersome preparation process and achieve the effects of simple operation, avoiding the corrosion of equipment and chemical activation, and high effective specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

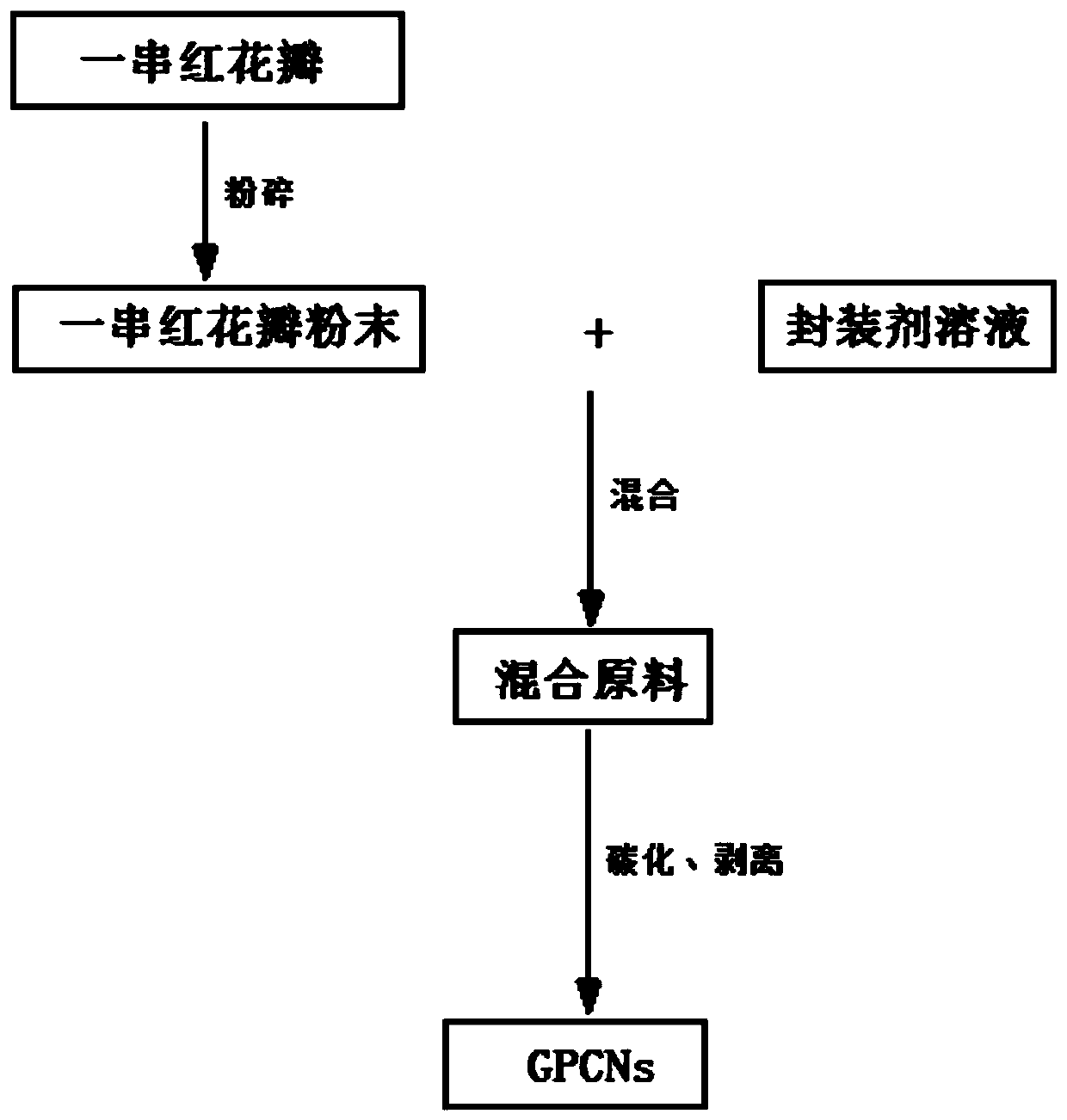

Method used

Image

Examples

Embodiment 1

[0088] Wash a string of red petals with clean water to remove impurities, and after drying, crush them to 80 mesh with a pulverizer. Take 5g of a string of red petals powder and 15g of NaCl solids, add them to 50ml of water and mix evenly, heat and evaporate the water to dryness to obtain a string of red petals encapsulated by NaCl. Next, after placing the encapsulated sample in a high-temperature tube furnace, the N 2 Under the protection of 5℃·min -1 Raise the temperature to 800°C, carbonize at a constant temperature for 2 hours, take out the carbide at room temperature, and wash it with ultrapure water several times to NaCl. Finally, the product was dried to constant weight to obtain 1.01 g of a string of red petal-based graphene-like porous carbon nanosheets.

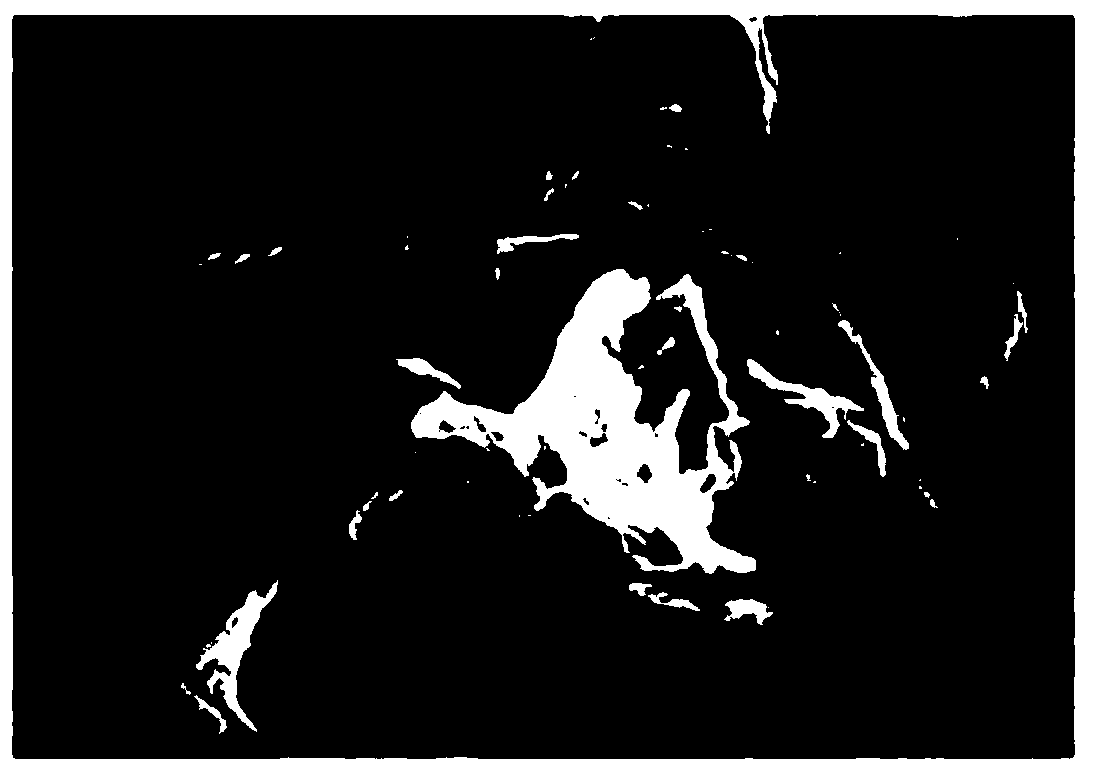

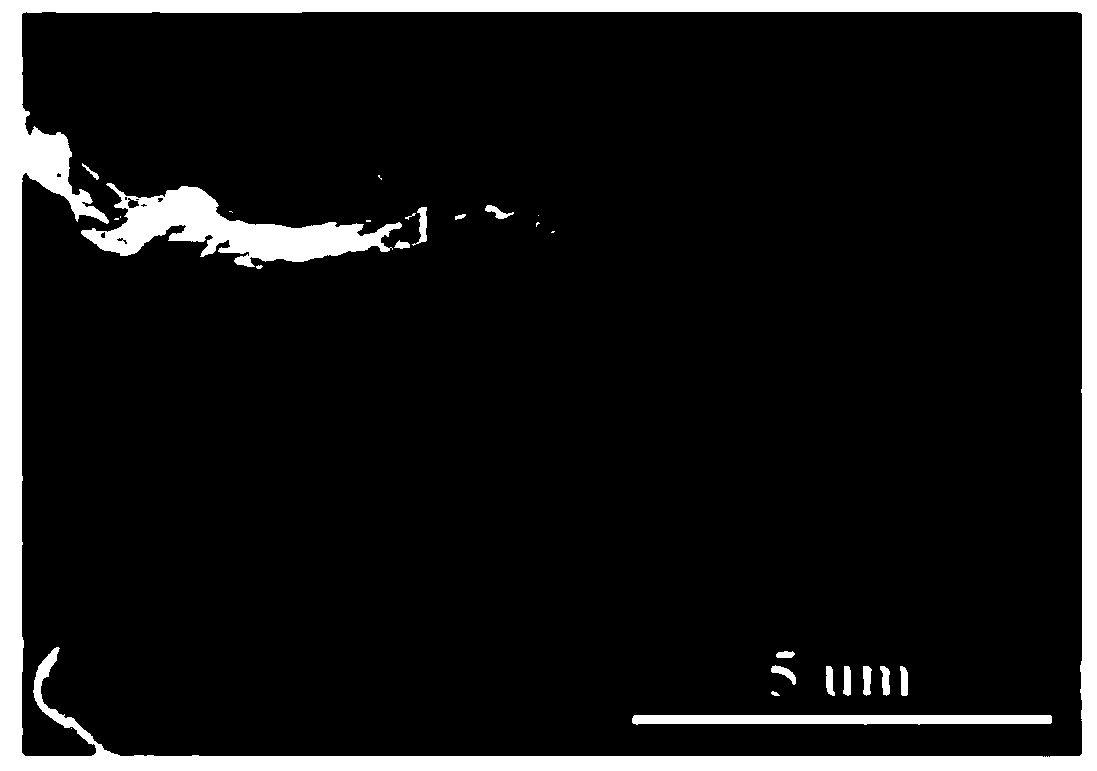

[0089] The prepared porous carbon nanosheets as figure 1 Shown has the graphene-like porous nanosheet structure, and the thickness of the prepared nanosheets is mostly concentrated in the range of 20-50nm; as f...

Embodiment 2

[0091] Wash a string of red petals with clean water to remove impurities, and after drying, crush them to 80 mesh with a pulverizer. Take 5g of a string of red petals powder and 15g of NaCl solids, add them to 50ml of water and mix evenly, heat and evaporate the water to dryness to obtain a string of red petals encapsulated by NaCl. Next, after placing the encapsulated sample in a high-temperature tube furnace, the N 2 Under the protection of 5℃·min -1 Raise the temperature to 700°C, carbonize at a constant temperature for 2 hours, take out the carbide at room temperature, and wash it with ultrapure water several times to NaCl. Finally, the product was dried to constant weight to obtain 1.15 g of a string of red petal-based graphene-like porous carbon nanosheets.

[0092] When the prepared porous carbon nanosheets are used as electrode materials for supercapacitors, at 0.5A g -1 Under the current density of , the specific capacitance of graphene-like carbon nanosheets is 32...

Embodiment 3

[0094] Wash a string of red petals with clean water to remove impurities, and after drying, crush them to 80 mesh with a pulverizer. Take 5g of a string of red petals powder and 15g of NaCl solid and add them to 100ml of water to mix evenly, heat and evaporate the water to dryness to obtain a string of red petals encapsulated by NaCl. Next, after placing the encapsulated sample in a high-temperature tube furnace, the N 2 Under the protection of 5℃·min -1 Raise the temperature to 900°C, carbonize at a constant temperature for 2 hours, take out the carbide at room temperature, and wash it with ultrapure water several times to NaCl. Finally, the product was dried to constant weight to obtain a string of red petal-based graphene-like porous carbon nanosheets of 0.83g

[0095] When the prepared porous carbon nanosheets are used as electrode materials for supercapacitors, at 0.5A g -1 The specific capacitance of graphene-like carbon nanosheets is 318F·g under the current density ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com