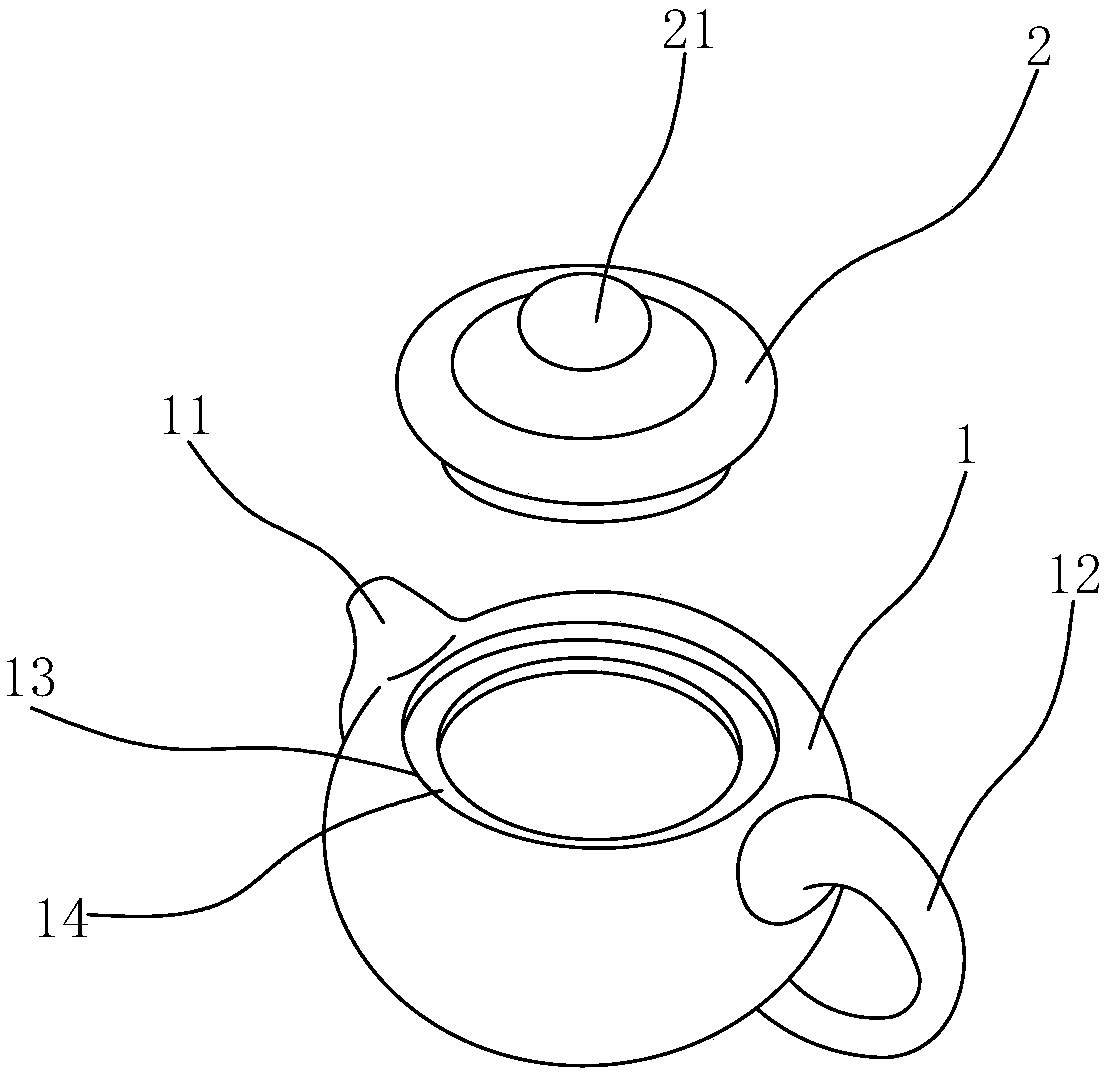

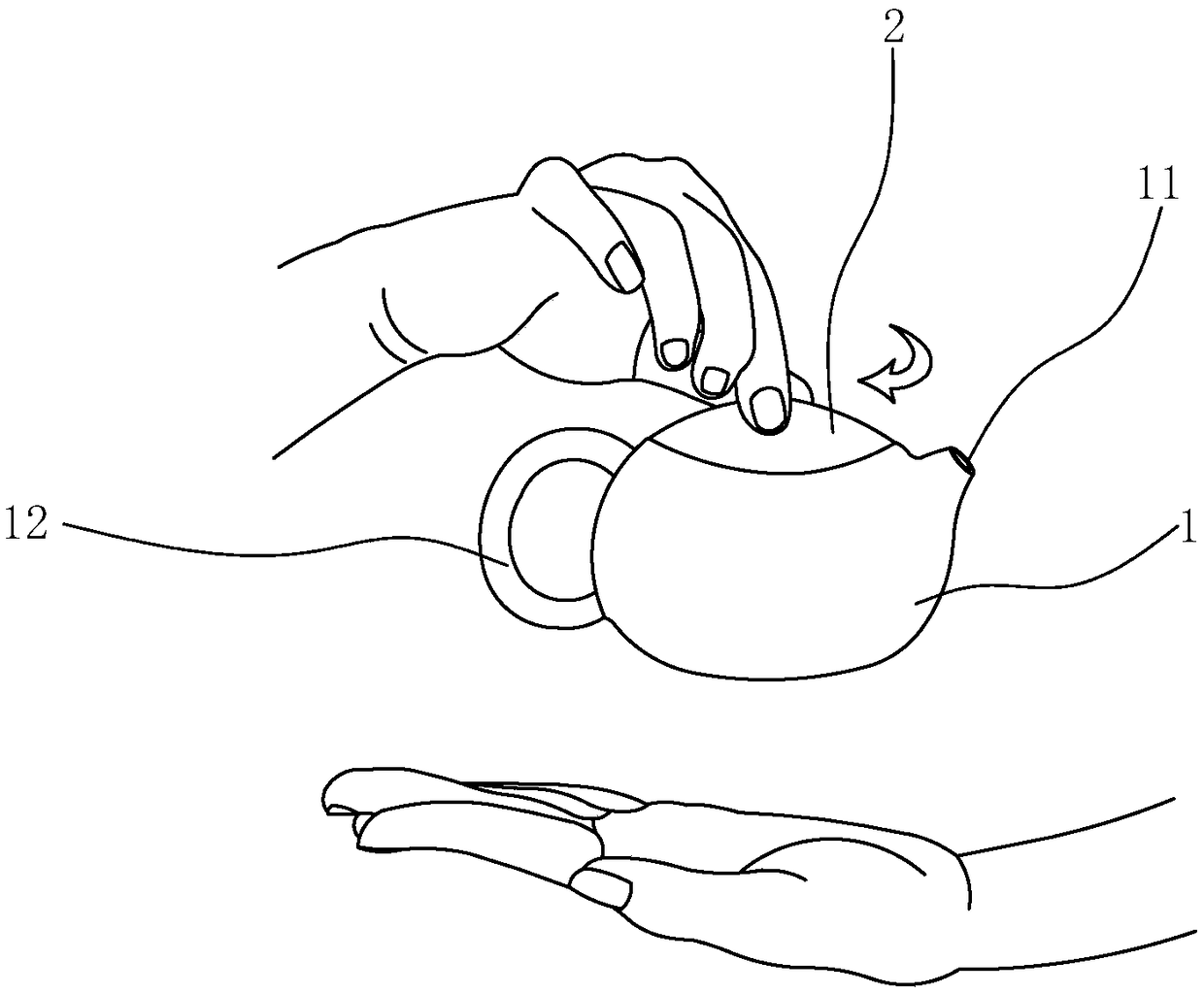

Mutton-fat jade porcelain pot capable of rotating in air and preparation method thereof

The technology of a porcelain pot and suet is applied in the field of suet jade porcelain pot and its preparation, which can solve the problems of insufficient water or tea from the spout, poor tightness between the pot body and the pot lid, and no other functions, etc. Achieve the effect of increasing practical value and artistic value, enhancing sealing, and enhancing water output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] Further, a method for preparing a suet jade porcelain pot that can be rotated in the air, comprising the following steps:

[0027] (1), natural weathering of potassium feldspar, kaolin, quartz, granite, muscovite, diopside and tremolite for 5-7 days;

[0028] (2), mix and crush naturally weathered potassium feldspar, kaolin, quartz, granite, muscovite, diopside, tremolite and other raw materials, sieve, and wet ball mill to obtain mud, wherein, in wet ball mill , according to the material: ball: the weight ratio of water=1:1.5-1.8:0.8-1.2 is carried out, and the ball milling time is 32-36h;

[0029] (3), stale the mud prepared in step (2) for 24-36 hours at a temperature of 30-45°C, then repeatedly beat and squeeze the stale mud in a certain order until it can be seen after being scratched with a knife. Shine on the mud section;

[0030] (4), inject the mud processed in step (3) into the gypsum mold, and make the pot body body and the pot lid body by grouting molding....

Embodiment 1

[0034] A suet jade porcelain pot that can be rotated in the air is composed of the following raw materials in parts by weight: 20 parts of potassium feldspar, 30 parts of kaolin, 50 parts of quartz, 25 parts of granite, 10 parts of muscovite, and 12 parts of diopside , tremolite 10 parts, saline soil 1 part, alumina 16 parts, boron carbide 6 parts, silicon nitride 5 parts, zirconia 1.2 parts, lanthanum oxide 0.8 parts, vanadium pentoxide 0.2 parts, beryllium oxide 0.3 parts, carboxylate 0.6 parts of sodium methylcellulose, 0.3 parts of titanium oxide;

[0035] Its preparation method comprises the following steps:

[0036] (1), natural weathering of potassium feldspar, kaolin, quartz, granite, muscovite, diopside and tremolite for 7 days;

[0037] (2), mix and crush naturally weathered potassium feldspar, kaolin, quartz, granite, muscovite, diopside, tremolite and other raw materials, sieve, and wet ball mill to obtain mud, wherein, in wet ball mill , by material: ball: the w...

Embodiment 2

[0043] A suet jade porcelain pot that can be rotated in the air is composed of the following raw materials in parts by weight: 25 parts of potassium feldspar, 25 parts of kaolin, 60 parts of quartz, 20 parts of granite, 15 parts of muscovite, and 8 parts of diopside , tremolite 6 parts, saline soil 3 parts, alumina 12 parts, boron carbide 8 parts, silicon nitride 8 parts, zirconia 0.8 parts, lanthanum oxide 0.5 parts, vanadium pentoxide 0.5 parts, beryllium oxide 0.15 parts, carboxylate 0.8 part of sodium methylcellulose, 0.1 part of titanium oxide;

[0044] Its preparation method comprises the following steps:

[0045] (1), natural weathering of potassium feldspar, kaolin, quartz, granite, muscovite, diopside and tremolite for 5 days;

[0046] (2), mix and crush naturally weathered potassium feldspar, kaolin, quartz, granite, muscovite, diopside, tremolite and other raw materials, sieve, and wet ball mill to obtain mud, wherein, in wet ball mill , by material: ball: the wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com