Method for synthesizing alpha-quaternary carbon amino acid

A synthetic method and amino acid technology, applied in the field of synthesis of α-quaternary carbon amino acids, can solve difficult problems such as the synthesis of α-quaternary carbon amino acids

- Summary

- Abstract

- Description

- Claims

- Application Information

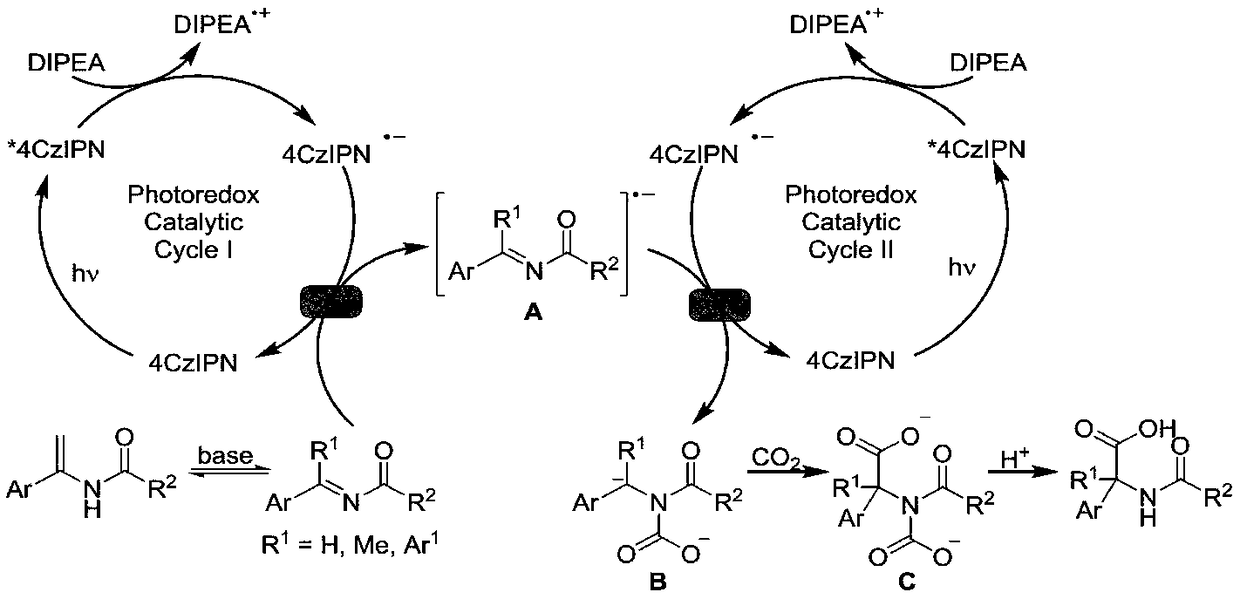

AI Technical Summary

Problems solved by technology

Method used

Image

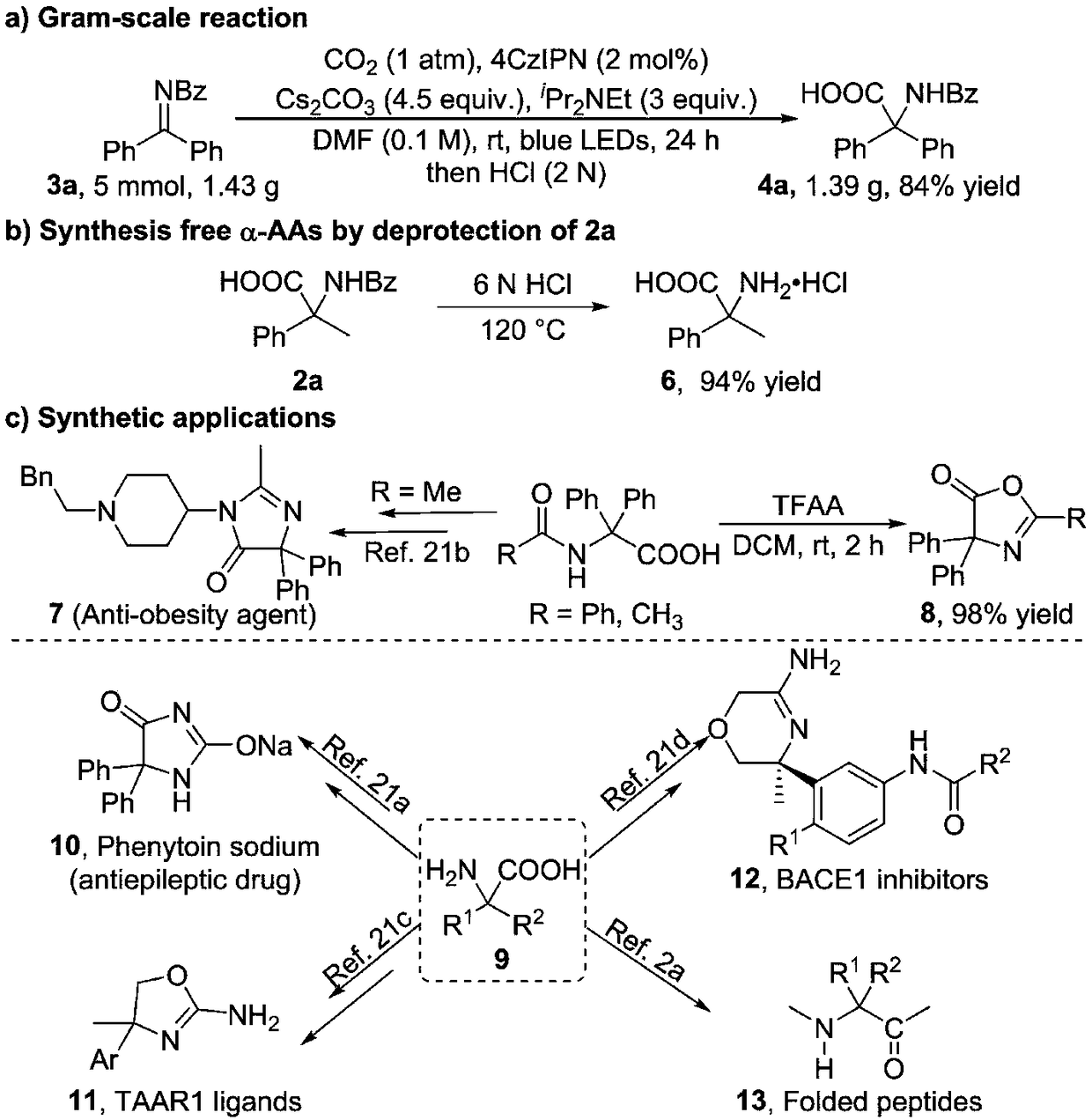

Examples

Embodiment 1

[0062] To a dry Schlenk tube (10 mL) containing magnetons was added the reaction substrate (0.2 mmol), 4CzIPN (4 mg, 0.004 mmol, 2 mol%). The Schlenk tube was then transferred into the glove box, where it was loaded with Cs 2 CO 3 (294mg, 0.9mmol, 4.5 times equivalent). Remove the Schlenk tube from the glove box and connect to a CO 2 On the double row pipe of the steel cylinder, pump and charge CO on the double row pipe 2 At least 3 times, drain the N in the tube 2 , so that the tube is filled with CO 2 gas. Then in CO 2 Add DMF (2mL) and i PR 2 NEt (100 μL, 3 equiv.). Finally, the reaction solution was placed 2-4 cm away from the 30W blue LED, and stirred at room temperature (25° C.) for 4 hours. The mixture was then quenched with 1 mL of water, 2.5 mL of ethyl acetate and 2 mL of 2N hydrochloric acid, then directly concentrated and spin-dried. The residue was purified by flash column chromatography (first with petroleum ether / ethyl acetate 5 / 1 (v / v) and 0.2-0.3% g...

Embodiment 2

[0070] To a dry Schlenk tube (10 mL) containing magnetons was added the reaction substrate (0.2 mmol), 4CzIPN (2 mg, 0.002 mmol, 1 mol%). The Schlenk tube was then transferred into a glove box, which contained K 2 CO 3 (139 mg, 1.0 mmol, 5 equivalents). Remove the Schlenk tube from the glove box and connect to a CO 2 On the double row pipe of the steel cylinder, pump and charge CO on the double row pipe 2 At least 3 times, drain the N in the tube 2 , so that the tube is filled with CO 2 gas. Then in CO 2 Add DMF (2mL) and i PR 2 NEt (67 μL, 2 equiv). Finally, the solution was placed 2-4cm away from the 30W blue LED, and stirred at room temperature (25°C) for 4 hours. The mixture was then quenched with 1 mL of water, 2.5 mL of ethyl acetate and 2 mL of 2N hydrochloric acid, then directly concentrated and spin-dried. The residue was purified by flash column chromatography (first with petroleum ether / ethyl acetate 5 / 1 (v / v) and 0.2-0.3% glacial acetic acid, then with p...

Embodiment 3

[0072] To a dry Schlenk tube (10 mL) containing magnetons was added the reaction substrate (0.2 mmol), 4CzIPN (10 mg, 0.01 mmol, 5 mol%). The Schlenk tube was then transferred into a glove box, where it was filled with Na 2 CO 3 (106mg, 1.0mmol, 5 times equivalent). Remove the Schlenk tube from the glove box and connect to a CO 2 On the double row pipe of the steel cylinder, pump and charge CO on the double row pipe 2 At least 3 times, drain the N in the tube 2 , so that the tube is filled with CO 2 gas. Then in CO 2 Add DMF (2mL) and i PR 2 NEt (167 μL, 5 equivalents). Finally, the solution was placed 2-4 cm away from the 30W blue LED, and stirred at room temperature (25° C.) for 4 hours. The mixture was then quenched with 1 mL of water, 2.5 mL of ethyl acetate and 2 mL of 2N hydrochloric acid, then directly concentrated and spin-dried. The residue was purified by flash column chromatography (first with petroleum ether / ethyl acetate 5 / 1 (v / v) and 0.2-0.3% glacial a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com