Flavobacterium johnsoniae producing alginate lyase strain

A technology of Flavobacterium johnsonii and Flavobacterium johnsonii, applied in the biological field, can solve the problems of difficulty in separation, high price, limited popularization and application, etc., and achieves the effects of simple nutritional requirements, shortened production cycle, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

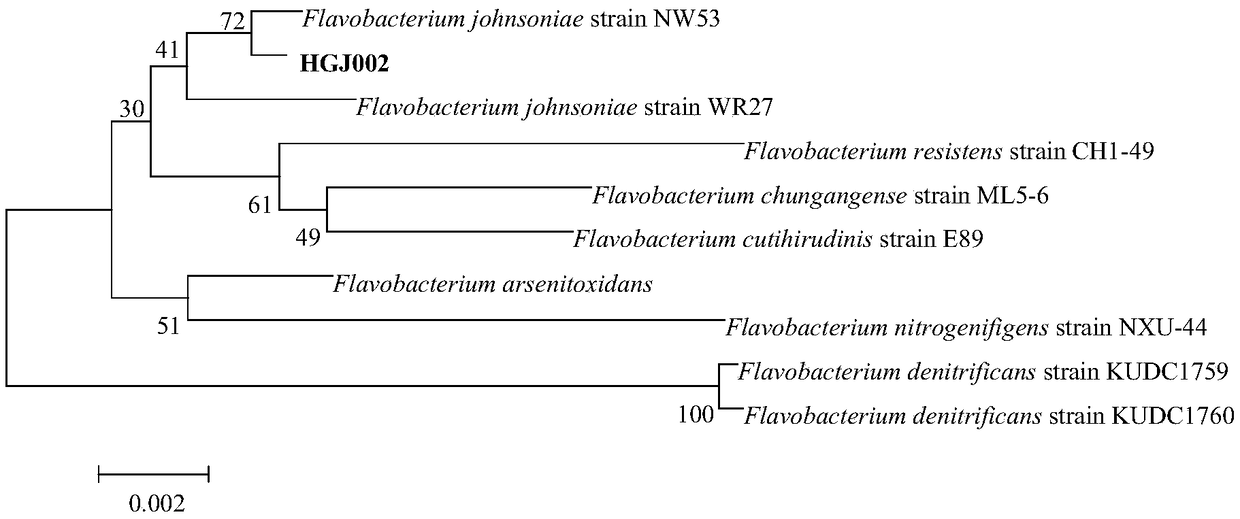

[0020] Example 1: Isolation and identification of Flavobacterium johnsoniae (Flavobacterium johnsoniae) WX-11 and preservation of bacterial strains

[0021] (1) Isolation and screening of Flavobacterium johnsoniae WX-11

[0022] Dried kelp was purchased in the supermarket, cut into blocks, wrapped in gauze, and placed in conical flasks filled with river water, soil or tap water from the Jiangnan University campus. After incubation for 2 weeks, samples were taken. Shake the obtained sample in physiological saline with magnetic beads for 2 hours, let it stand overnight, inoculate it into a liquid medium with sodium alginate as the only carbon source, and culture it at 30°C and 220r / min until the blocky kelp is degraded and then transferred , five consecutive passages. The culture medium of continuous acclimatization for 5 generations was diluted with normal saline for 10 -7 、10 -8 、10 -9 times, spread on the solid medium with sodium alginate as the only carbon source on the ...

Embodiment 2

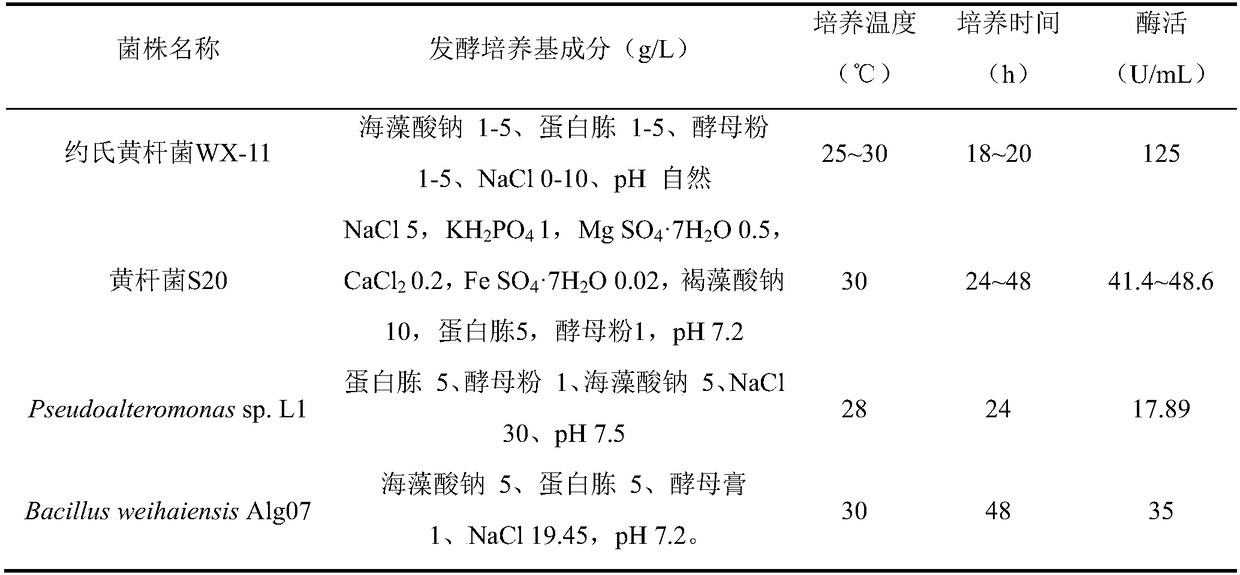

[0029] Embodiment 2: Preparation of alginate lyase by Flavobacterium johnsoniae WX-11

[0030] The method for producing alginate lyase by Flavobacter johnii WX-11 described in embodiment 1, the steps are as follows:

[0031] (1) Strain activation: inoculate Flavobacterium johnii WX-11 in a solid medium, and culture it for 24 hours at 25-30°C to obtain an activated strain;

[0032](2) Seed solution preparation: take the activated strain obtained in step (1), inoculate it in a 250mL Erlenmeyer flask containing 50mL of seed medium, and cultivate it for 8 ~12h, the seed liquid is obtained;

[0033] (3) Fermentation liquid preparation: get the seed liquid that step (2) makes, inoculate in the fermentation medium by volume ratio 1~5%, at 25~30 ℃, cultivate under the condition of 150~220r / min 18~ After 20 hours, the cell fermentation liquid was obtained.

[0034] The formulations of seed medium and fermentation medium are: sodium alginate 1-5g / L, peptone 1-5g / L, yeast powder 1-5g / ...

Embodiment 3

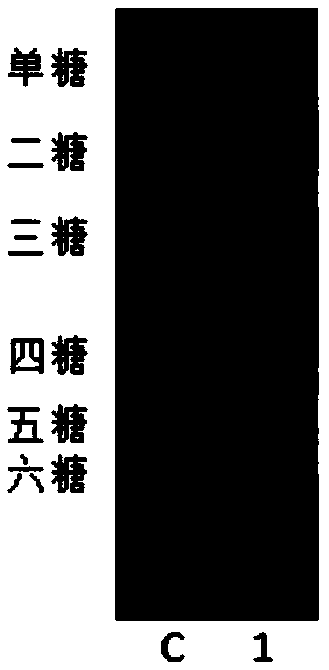

[0039] Example 3: Analysis of degradation products of alginate lyase produced by Flavobacterium johnsoniae (Flavobacterium johnsoniae) WX-11

[0040] Take 1 g of sodium alginate in 100 mL of 50 mM (pH 7.0) phosphate buffer, add the crude alginate lyase solution produced by Flavobacter johnii WX-11, enzymolyze it in a water bath at 40 °C for 24 hours, and pass thin-layer chromatography Analysis of degradation products. The results show( figure 2 ), the product after enzymatic hydrolysis of sodium alginate is mainly 2-6 sugars, no monosaccharides are detected, it is speculated that it is an endo-type alginate lyase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com