Process for synchronously producing ethyl alcohol, xylitol, lignin and cellulosic fiber pulp through straw enzymolysis and fermentation

A technology of cellulose fiber and cellulose pulp, applied in the direction of using microorganism/enzyme cellulose treatment, fermentation, fiber raw material treatment, etc., can solve problems such as increased production cost, low product yield, environmental pollution, etc., and save equipment cost. , Reduce process cost and overcome the effect of long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

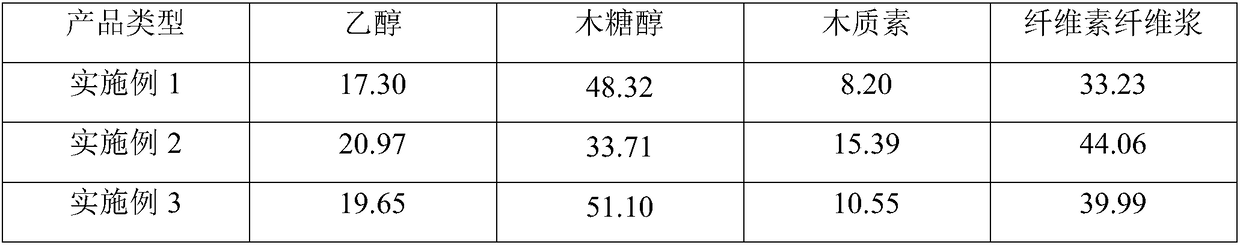

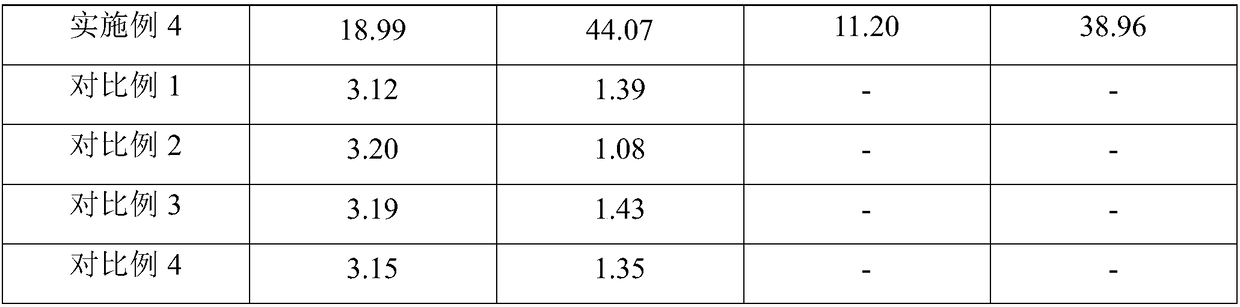

Examples

Embodiment 1

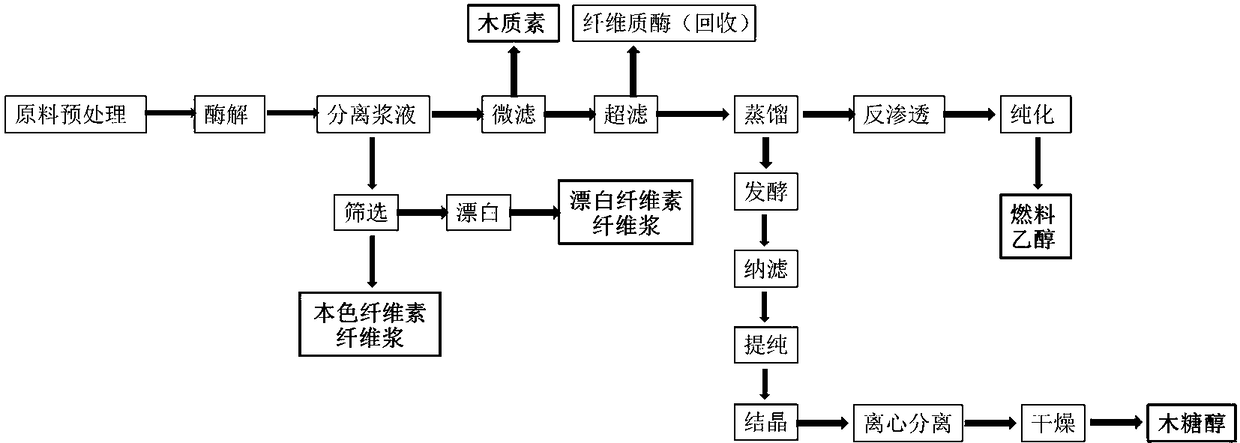

[0024] A process for simultaneous production of ethanol, xylitol, lignin, and cellulose fiber pulp by enzymolysis and fermentation of straw ( figure 1 shown), including the following steps:

[0025] (1) Raw material pretreatment: Knead corn stalks and sorghum stalks into 4-8cm filaments with a kneading machine, and knead them softly without induration;

[0026] (2) Enzymatic hydrolysis: add 1 kg of corn stalk cellulosic enzyme-05 to every 200 kg of pretreated corn stalks and sorghum stalks and mix well, then add water and pH buffer solution respectively, then pack them in sealed double-layer material bags, and store them indoors , the enzymolysis temperature is 2-30°C, the enzymolysis time is 7-150 days, and the pH value is ≤7;

[0027] (3) Separation: After the enzymolysis is completed, put the enzymolyzate directly into the vacuum pulp washer, separate the liquid from the cellulose pulp by squeezing and filtering, and send the liquid into a microfiltration device to extract...

Embodiment 2

[0032] A process for simultaneous production of ethanol, xylitol, lignin, and cellulose fiber pulp by enzymolysis and fermentation of straw ( figure 1 shown), including the following steps:

[0033] (1) Raw material pretreatment: knead wheat straw and barley straw into 4-8cm filaments with a kneading machine respectively, and knead them softly without induration;

[0034] (2) Enzymatic hydrolysis: add 1.5kg of wheat straw cellulosic enzyme-05 to every 200kg of pretreated wheat straw and barley straw and mix evenly, then add water and pH buffer solution respectively, and then pack them in sealed double-layer material bags. Storage, the enzymolysis temperature is 2-30°C, the enzymolysis time is 7-150 days, and the pH value is ≤7;

[0035] (3) Separation: After the enzymolysis is completed, put the enzymolyzate directly into the vacuum pulp washer, separate the liquid from the cellulose pulp by squeezing and filtering, and send the liquid into a microfiltration device to extract...

Embodiment 3

[0040] A process for simultaneous production of ethanol, xylitol, lignin, and cellulose fiber pulp by enzymolysis and fermentation of straw ( figure 1 shown), including the following steps:

[0041] (1) Raw material pretreatment: Knead rice straw and grain straw into 4-8cm filaments with a kneading machine respectively, and knead them softly without induration;

[0042] (2) Enzymolysis: add 1.5kg of rice straw cellulosic enzyme-05 to every 200kg of pretreated rice straw and grain straw and mix evenly, then add water and pH buffer solution respectively, and then pack it in a sealed double-layer material bag. Storage, the enzymolysis temperature is 2-30°C, the enzymolysis time is 7-150 days, and the pH value is ≤7;

[0043] (3) Separation: After the enzymolysis is completed, put the enzymolyzate directly into the vacuum pulp washer, separate the liquid from the cellulose pulp by squeezing and filtering, and send the liquid into a microfiltration device to extract lignin, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com