Process for synchronously producing ethyl alcohol, xylopyranose, lignin and cellulosic fiber pulp through straw enzymolysis and fermentation

A cellulose fiber and lignin technology, applied in the direction of using microorganism/enzyme cellulose treatment, fermentation, fiber raw material treatment, etc., can solve the problems of increased production cost, environmental pollution, high water consumption, etc., to save equipment costs and overcome time Long, simple filtering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

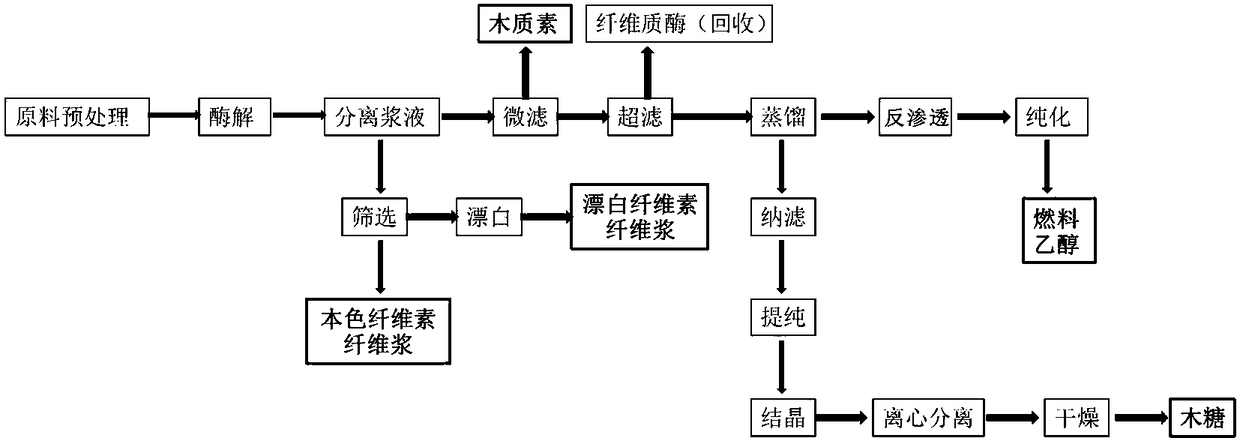

[0024] A process for simultaneous production of ethanol, xylose, lignin, and cellulose fiber pulp by enzymolysis and fermentation of straw ( figure 1 shown), including the following steps:

[0025] (1) Raw material pretreatment: Knead corn stalks and sorghum stalks into 4-8cm filaments with a kneading machine, and knead them softly without induration;

[0026] (2) Enzymatic hydrolysis: Add 1 kg of corn stalk cellulosic enzyme-01 to every 200 kg of pretreated corn stalks and sorghum stalks and mix evenly, then add water and pH buffer respectively, then pack them in sealed double-layer bags and store them indoors , the enzymolysis temperature is 2-30°C, the enzymolysis time is 7-150 days, and the pH value is ≤7;

[0027] (3) Separation: After the enzymatic hydrolysis is completed, put the enzymatic hydrolyzate directly into the vacuum pulp washer, separate the liquid from the cellulose pulp by squeezing and filtering, and send the liquid into the microfiltration and ultrafiltra...

Embodiment 2

[0032] A process for simultaneous production of ethanol, xylose, lignin, and cellulose fiber pulp by enzymolysis and fermentation of straw ( figure 1 shown), including the following steps:

[0033] (1) Raw material pretreatment: knead wheat straw and barley straw into 4-8cm filaments with a kneading machine respectively, and knead them softly without induration;

[0034] (2) Enzymatic hydrolysis: Add 1.5kg of wheat straw cellulosic enzyme-01 for every 200kg of pretreated wheat straw and barley straw, mix evenly, then add water and pH buffer solution respectively, and then pack it in a sealed double-layer material bag, Indoor storage, enzymolysis temperature is 2-30°C, enzymolysis time is 7-150 days, pH value ≤7;

[0035] (3) Separation: After the enzymatic hydrolysis is completed, put the enzymatic hydrolyzate directly into the vacuum pulp washer, separate the liquid from the cellulose pulp by extrusion and filtration, and send the liquid into the microfiltration and ultrafil...

Embodiment 3

[0040] A process for simultaneous production of ethanol, xylose, lignin, and cellulose fiber pulp by enzymolysis and fermentation of straw ( figure 1 shown), including the following steps:

[0041] (1) Raw material pretreatment: Knead rice straw and grain straw into 4-8cm filaments with a kneading machine respectively, and knead them softly without induration;

[0042] (2) Enzymolysis: add 1.5kg of rice straw cellulosic enzyme-01 to every 200kg of pretreated rice straw and grain straw and mix evenly, then add water and pH buffer solution respectively, and then pack it in a sealed double-layer material bag. Storage, the enzymolysis temperature is 2-30°C, the enzymolysis time is 7-150 days, and the pH value is ≤7;

[0043] (3) Separation: After the enzymolysis is completed, put the enzymolyzate directly into the vacuum pulp washer, separate the liquid from the cellulose pulp by squeezing and filtering, and send the liquid into a microfiltration device to extract lignin, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com