Non-oriented electrician steel thin strip and production method thereof

A technology of grain-oriented electrical steel and production method, which is applied in the directions of manufacturing tools, heat treatment baths, heat treatment equipment, etc., can solve the problems of reduced efficiency, restricted heating speed, and difficulty in improving heating speed, and achieves improved magnetic properties, fast heating speed, and fast heating. Effects of heating and oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

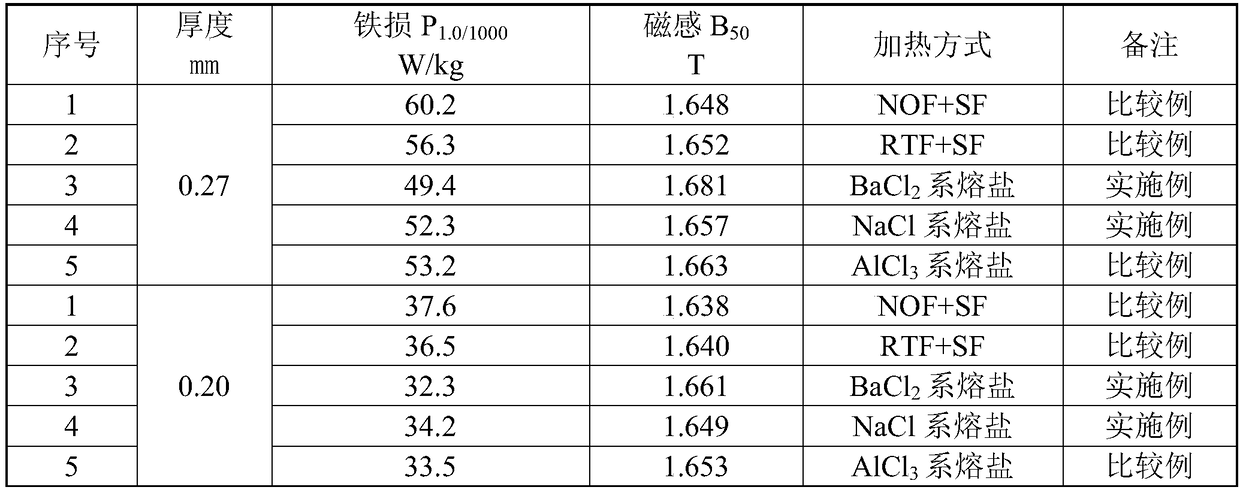

Examples

Embodiment Construction

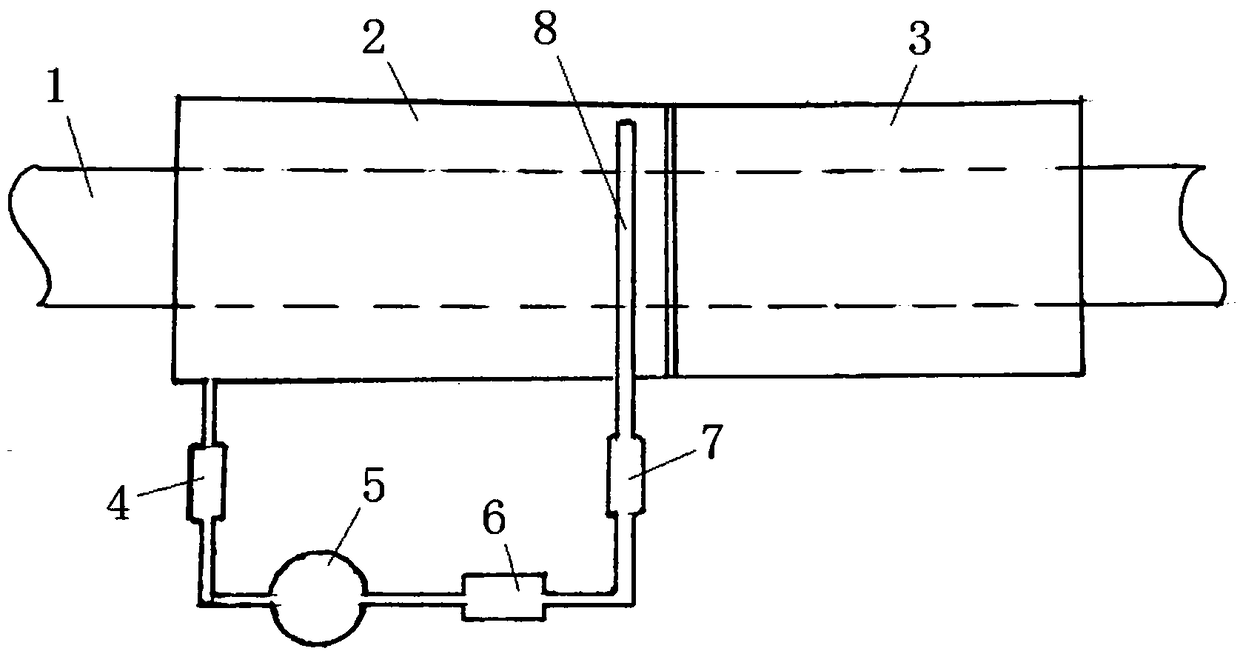

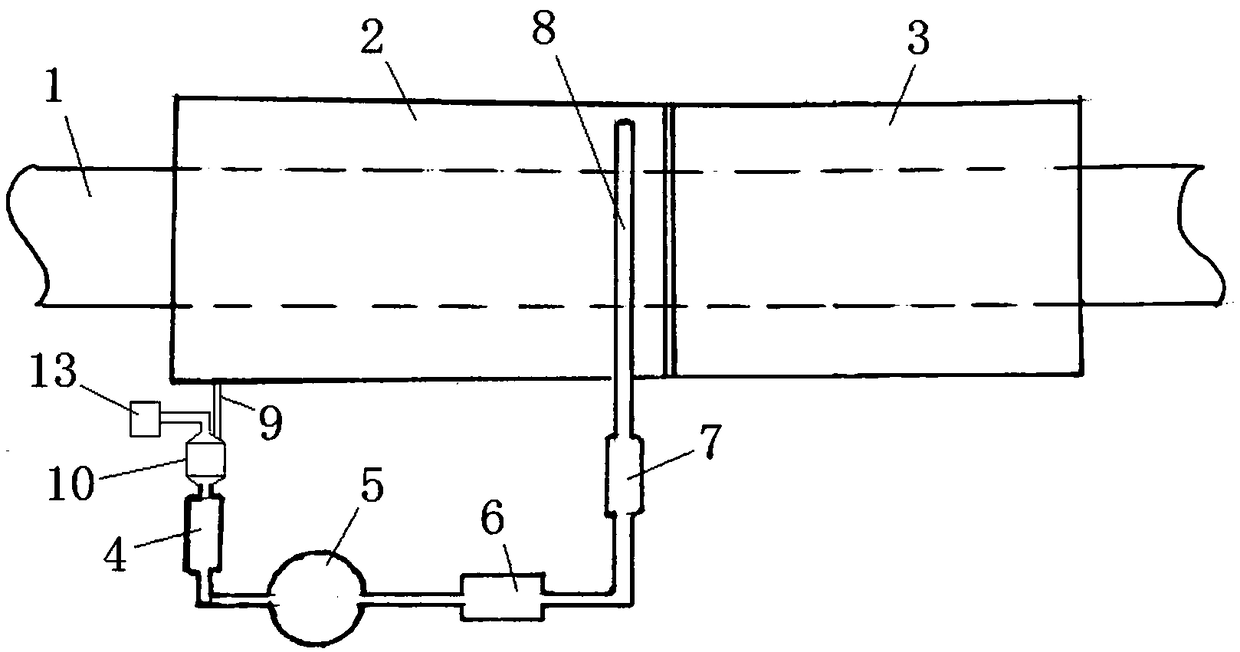

[0029] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

[0030] After smelting, continuous casting, hot rolling, and then pickling and cold rolling to the finished thickness and width of the electrical steel strip, annealing is required to obtain the required properties.

[0031] The invention discloses a non-oriented electrical steel strip, which contains chemical components and weight percentages: C0.0020-0.0030%, Si 3.0-3.20%, Mn 0.15-0.25%, S 0.0006-0.0010%, Al 1 -1.5%, N0.0015-0.0025%, Sn 0.008-0.012%; the rest is Fe and unavoidable impurities.

[0032]The raw materials involved in the present invention can be obtained through converter smelting a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com