Crucible for quasi-monocrystalline silicon ingot casting and taking silica film as barrier layer

A technology of quasi-single crystal silicon and silicon dioxide, which is applied in the field of crucibles for quasi-single crystal silicon ingots, can solve the problems of increasing the cost of ingots, the limited effect of the width of the red zone at the bottom of the silicon ingots, etc., so as to improve the utilization rate and structure. Dense and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

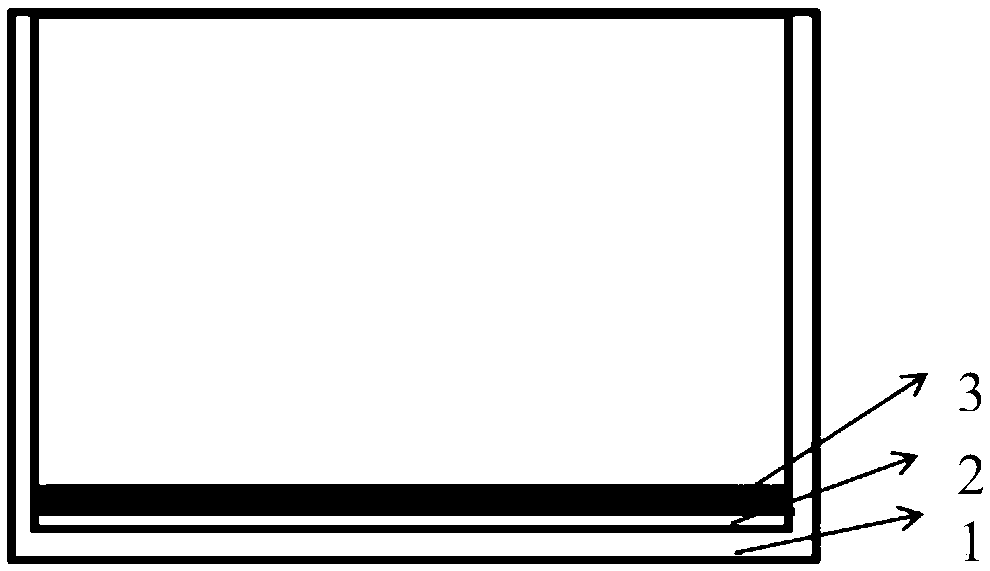

[0028] (1) Provide an inner diameter of 175*175mm and a crucible with a height of 190mm, spray a layer of silicon nitride coating on the inner surface of the base of the crucible, and let it dry naturally;

[0029] (2) Provide a solar-grade monocrystalline silicon wafer with a thickness of 0.2mm and a specification of 170*170mm;

[0030] (3) Anneal at 900°C for 15 minutes by thermal oxidation method on the above-mentioned solar-grade monocrystalline silicon wafer, grow silicon dioxide on both sides, and paste it on the inner bottom of the crucible through high-purity silica sol;

[0031] The SiO 2 The thickness of the film is 10nm;

[0032] (4) Then, a seed crystal is set on the barrier layer at the bottom of the crucible, and silicon material is set on the seed crystal, followed by heating, melting, crystal growth, annealing, and cooling to obtain a quasi-single crystal silicon ingot.

[0033] The schematic diagram of the silicon nitride coating, barrier layer, seed crystal...

Embodiment 2

[0037] (1) Provide an inner diameter of 175*175mm and a crucible with a height of 190mm, spray a layer of silicon nitride coating on the inner surface of the base of the crucible, and let it dry naturally;

[0038] (2) Provide a solar-grade monocrystalline silicon wafer with a thickness of 0.2mm and a specification of 170*170mm;

[0039] (3) Anneal at 900°C for 30 minutes by thermal oxidation method on the above-mentioned solar-grade monocrystalline silicon wafer, grow silicon dioxide on both sides, and paste it on the inner bottom of the crucible through high-purity silica sol;

[0040] The SiO 2 The thickness of the film is 15nm;

[0041] (4) Then, a seed crystal is set on the barrier layer at the bottom of the crucible, and silicon material is set on the seed crystal, followed by heating, melting, crystal growth, annealing, and cooling to obtain a quasi-single crystal silicon ingot.

[0042] The minority carrier lifetime in the bottom region of the quasi-single crystal si...

Embodiment 3

[0044] (1) Provide an inner diameter of 175*175mm and a crucible with a height of 190mm, spray a layer of silicon nitride coating on the inner surface of the base of the crucible, and let it dry naturally;

[0045] (2) Provide a solar-grade monocrystalline silicon wafer with a thickness of 0.2mm and a specification of 170*170mm;

[0046] (3) Anneal at 1000°C for 30 minutes by thermal oxidation method on the above-mentioned solar-grade monocrystalline silicon wafer, grow silicon dioxide on both sides, and paste it on the inner bottom of the crucible through high-purity silica sol;

[0047] The SiO 2 The thickness of the film is 30nm;

[0048] (4) Then set the seed crystal on the bottom barrier layer in the crucible, and then set the silicon material on the seed crystal, after heating, melting, crystal growth, annealing, and cooling to obtain a 160*160*128mm quasi-single crystal silicon ingot .

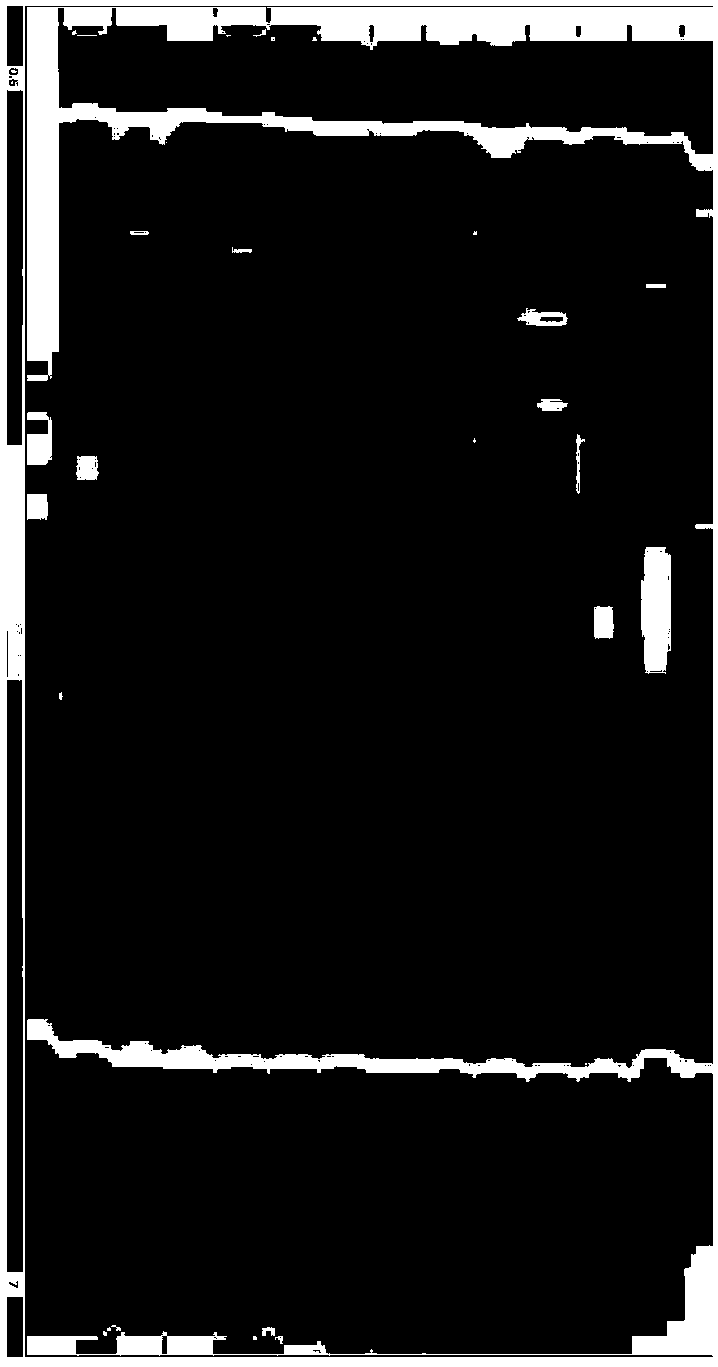

[0049] The minority carrier lifetime diagram of the quasi-single crystal silicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com