A kind of p-type algan epitaxial film and its preparation method and application

An epitaxial thin film, p-type technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, climate sustainability, etc., can solve industrial application difficulties, outstanding stability and repeatability problems, and the application value of deep ultraviolet light-emitting devices Difficulties and other problems, to achieve the effect of good repeatability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

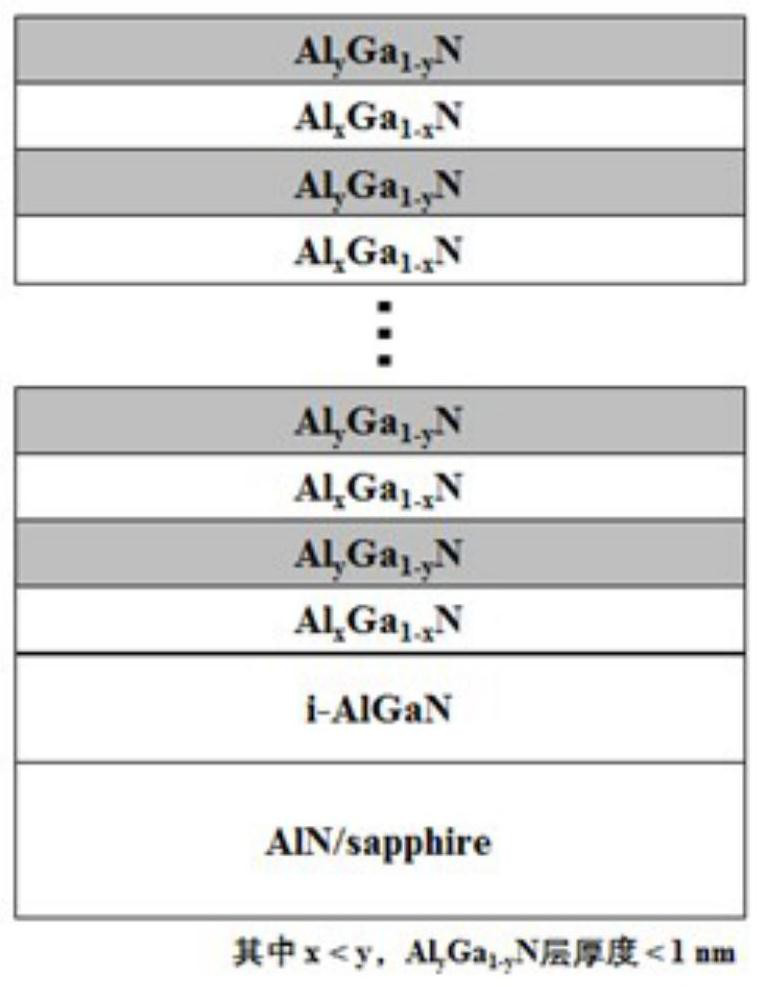

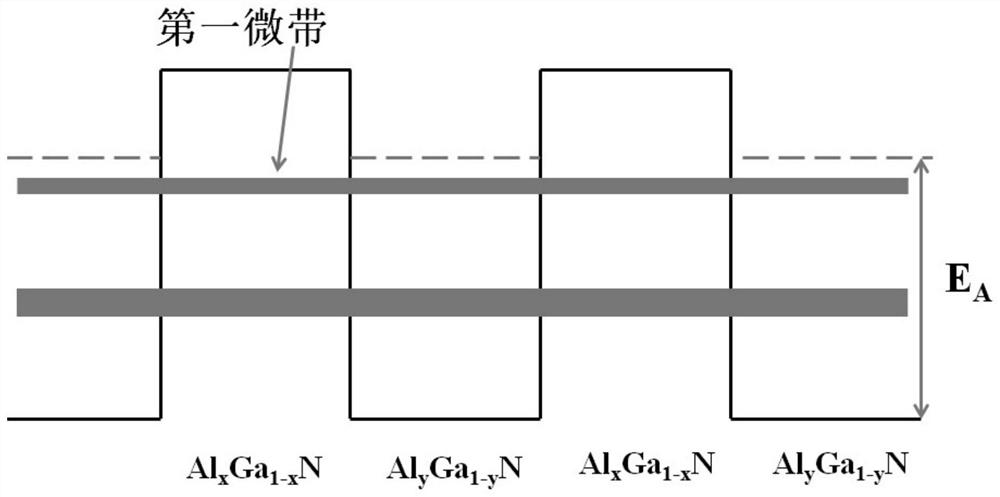

[0055] Example 1 Preparation of p-AlGaN epitaxial thin film with high Al composition

[0056] This embodiment provides a method for preparing a high Al composition p-AlGaN epitaxial film, including:

[0057] S1: Put the (0001) plane sapphire substrate in the reaction chamber of MOCVD equipment (3×2”Aixtron CCS FP-MOCVD), and pass H 2 , the reaction chamber pressure was 60mbar, baked at 1100°C for 600s, cleaned the substrate and lowered the temperature to 930°C, fed ammonia gas and TMAl to grow the AlN nucleation layer 10nm, then raised the temperature to 1250°C, and epitaxially grown AlN with a thickness of 1 Micron; then lower the temperature to 1160°C, pass through ammonia gas, TMAl and TMGa, and grow AlGaN with an Al composition of 0.6 and a thickness of 600 nanometers (i-AlGaN).

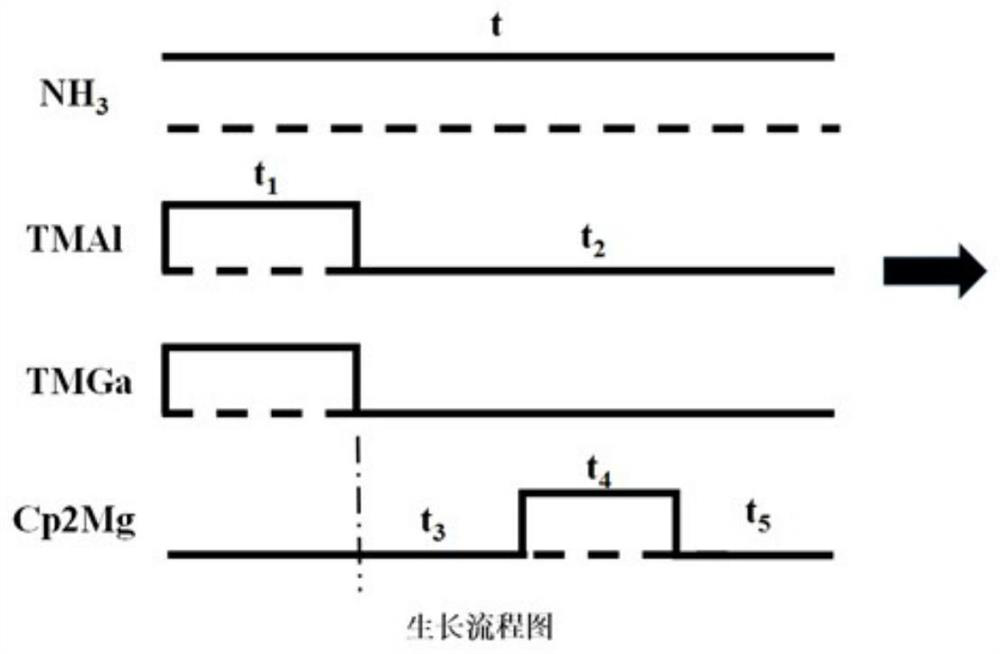

[0058] S2: Keep the atmosphere as hydrogen during the reaction period, and adjust the growth temperature to 1050°C to achieve stability.

[0059] S3: Control the molar ratio of organometallic s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com