Lithium ion battery electrolyte and lithium ion battery

A lithium-ion battery and electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problem of testing temperature range that cannot meet the high energy density requirements of batteries, and achieve improved low-temperature cycle performance, improved cycle performance, The effect of reducing impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

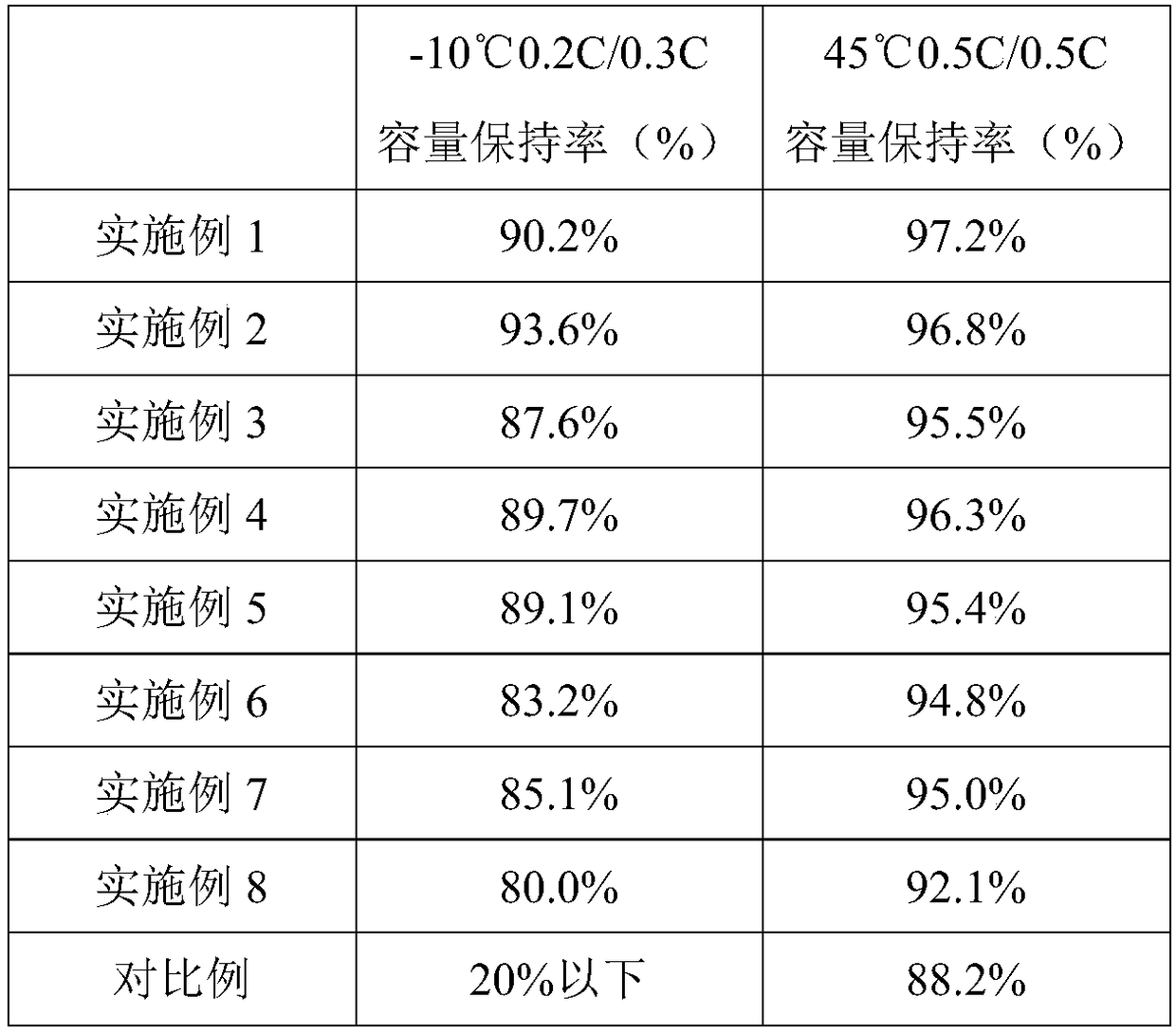

Examples

Embodiment 1

[0036] The lithium ion battery electrolyte of the present embodiment is made up of organic solvent, electrolyte lithium salt, low-impedance additive and functional additive; The lithium salt that adopts is lithium hexafluorophosphate; Composed of lithium phosphate; the functional additive used is tris(trimethylsilane) borate; the organic solvent used is composed of ethylene carbonate, ethyl methyl carbonate, diethyl carbonate and fluoroethylene carbonate, carbonic acid The mass ratio of vinyl ester 20%, ethyl methyl carbonate 50%, diethyl carbonate and fluoroethylene carbonate is 20:50:20:10; in lithium-ion battery electrolyte, the concentration of electrolyte lithium salt is 1.0mol / L, the mass fraction of lithium difluorophosphate is 0.5%, the mass fraction of lithium difluorobisoxalate phosphate is 1%, and the mass fraction of functional additives is 0.5%.

[0037] The lithium-ion battery electrolyte in this embodiment is obtained by adding electrolyte lithium salt, low-imp...

Embodiment 2

[0040]The lithium ion battery electrolyte of the present embodiment is made up of organic solvent, electrolyte lithium salt, low-impedance additive and functional additive; The lithium salt that adopts is lithium hexafluorophosphate; Composed of lithium phosphate; the functional additive used is tris(trimethylsilane) phosphate; the organic solvent used is composed of propylene carbonate, ethyl methyl carbonate, diethyl carbonate and fluoroethylene carbonate, propylene carbonate The mass ratio of ester, ethyl methyl carbonate, diethyl carbonate and fluoroethylene carbonate is 20:50:20:10; in lithium-ion battery electrolyte, the concentration of electrolyte lithium salt is 1.0mol / L, difluorophosphoric acid The mass fraction of lithium is 0.5%, the mass fraction of lithium difluorobisoxalate phosphate is 1%, and the mass fraction of functional additives is 0.5%.

[0041] The lithium-ion battery electrolyte in this embodiment is obtained by adding electrolyte lithium salt, low-imp...

Embodiment 3

[0044] The lithium ion battery electrolyte of the present embodiment is made up of organic solvent, electrolyte lithium salt, low-impedance additive and functional additive; It is composed of lithium difluorophosphate and lithium difluorobisoxalate phosphate; the functional additive used is tris(trimethylsilane) borate; the organic solvent used is composed of ethylene carbonate, ethyl methyl carbonate, diethyl carbonate ester and fluoroethylene carbonate, the mass ratio of ethylene carbonate, ethyl methyl carbonate, diethyl carbonate and fluoroethylene carbonate is 20:50:20:10; in lithium ion battery electrolyte, the concentration of lithium hexafluorophosphate 0.9mol / L, the concentration of lithium bis(fluorosulfonyl)imide is 0.1mol / L, the mass fraction of lithium difluorophosphate is 0.5%, the mass fraction of lithium difluorobisoxalate phosphate is 0.5%, functional additive The mass fraction is 0.5%.

[0045] The lithium-ion battery electrolyte in this embodiment is obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com