Negative pole piece and application thereof

A technology for a negative pole piece and a negative material layer, which is applied to the negative pole piece and its application fields, can solve the problems of low-potential film formation of electrolyte additives, co-insertion of solvents, deterioration of battery cycle performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

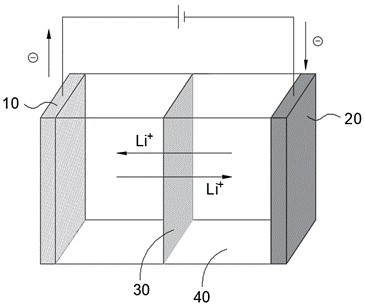

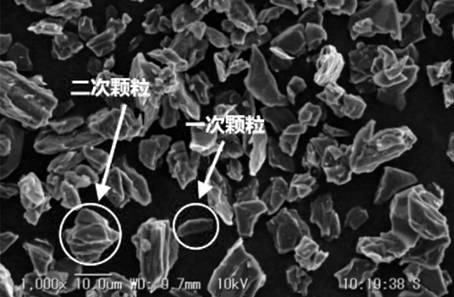

[0032] In order to improve the electrochemical performance of the secondary battery, the present application has designed a new negative electrode sheet, the carbon-based material in the negative electrode sheet is a system in which the primary particle carbon material and the secondary particle carbon material are mixed; the secondary particle Carbon material refers to a carbon material prepared from primary granular carbon material or carbon-coated primary granular carbon material as aggregate through secondary granulation, and in the carbon-based material, the surface of the secondary granular carbon material Covered with a carbon overlay. In some embodiments, the thickness of the carbon coating layer is 5nm-50nm. In some embodiments of the present application, the preparation method of the secondary granular carbon material includes: using the primary granular carbon material as an aggregate, adding one or more of pitch and resin to it and performing secondary granulation,...

Embodiment 1

[0052] A kind of preparation of negative pole sheet:

[0053] 1) Preparation of negative electrode sheet

[0054] The carbon-based material is obtained by mixing the primary granular carbon material and the secondary granular carbon material coated with a carbon coating layer. Among the carbon-based materials, the primary granular carbon material is primary granular graphite;

[0055] The preparation method of the secondary granular carbon material coated with carbon coating comprises: mixing the primary granular graphite with the bonded pitch and treating it in a reactor for secondary granulation to obtain the secondary granular graphite, adding to the secondary granular graphite The coated asphalt is stirred and carbonized at a temperature lower than 1000°C for carbon coating, and then sieved and demagnetized to obtain secondary granular graphite coated with an amorphous carbon coating layer. Mix carbon-based material, conductive agent (carbon black), thickener (carboxymet...

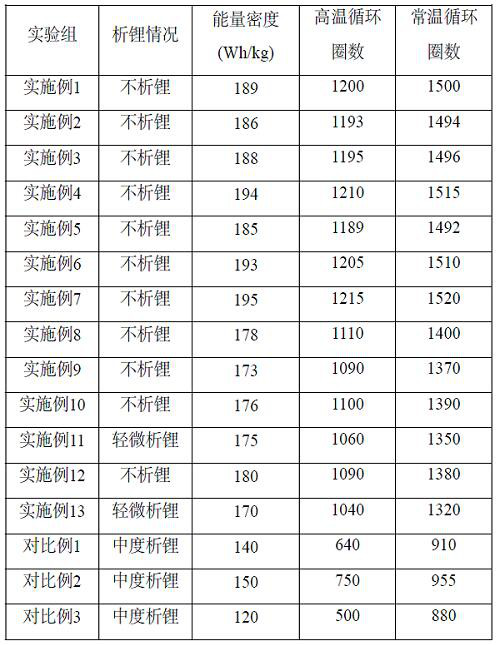

Embodiment 2- Embodiment 13

[0063] The carbon-based material in Example 2-13 is a blended system of primary particle graphite and secondary particle graphite coated with a carbon coating layer. The difference from Example 1 is that the overall structure of the carbon-based material in Example 2-13 The parameters are different from those in Example 1, and the specific structural information is shown in Table 1.

[0064] A secondary battery was prepared by the same method as in Example 1.

[0065] In order to highlight the beneficial effects of the present application, the following comparative examples are provided.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com