An electrolyte solution for improving the low-temperature performance of a lithium ion battery and a lithium ion battery containing the electrolyte solution

A lithium-ion battery, low-temperature performance technology, applied in the field of lithium-ion batteries, can solve the problems of deteriorating the high-temperature performance of the battery, can only be used for theoretical research, cannot be promoted, etc., to improve low-temperature cycle performance, improve interface stability, and improve Conductive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

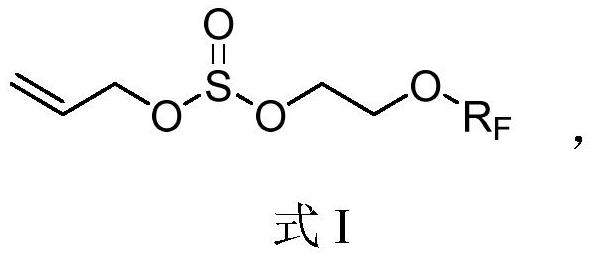

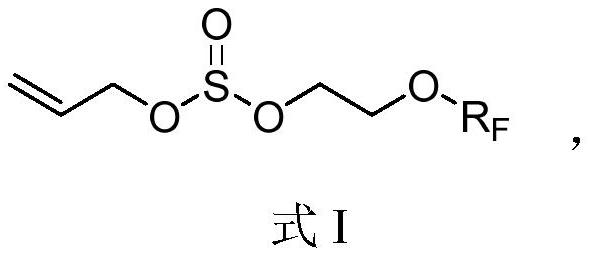

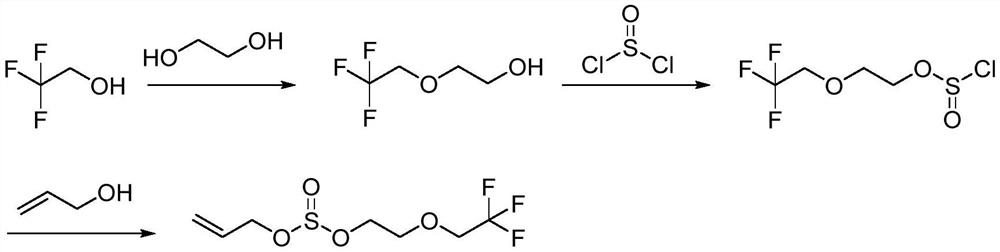

Method used

Image

Examples

Embodiment 1

[0029] Electrolyte preparation: In a glove box filled with argon, ethylene carbonate (EC), propylene carbonate (PC), dimethyl carbonate (DMC) and ethyl methyl carbonate (EMC) were mixed in a mass ratio of 2:1 : 3:4 mixed to make 1mol / L LiPF 6 Electrolyte, then add (2-trifluoroethoxyethyl) (allyl) sulfite accounting for 0.3% by weight of the electrolyte, and stir evenly to obtain the battery electrolyte of Example 1.

[0030] Battery assembly: with LiFePO 4 (LFP) positive electrode material and graphite negative electrode material are paired and assembled according to the ratio of negative electrode content (N) and positive electrode content (P) to be N / P=1.1 7Ah soft pack battery, and the electrolyte uses the electrolyte of embodiment 1.

Embodiment 2

[0032] Electrolyte preparation: In a glove box filled with argon, ethylene carbonate (EC), propylene carbonate (PC), dimethyl carbonate (DMC) and ethyl methyl carbonate (EMC) were mixed in a mass ratio of 2:1 : 3:4 mixed to make 1mol / L LiPF 6 Electrolyte, and then add (2-trifluoroethoxyethyl) (allyl) sulfite accounting for 0.5% of the mass ratio of the electrolyte, and stir evenly to obtain the battery electrolyte of Example 2.

[0033] Battery assembly: with LiNi 0.6 co 0.2 mn 0.2 o 2 (NCM622) The positive electrode material and the graphite negative electrode material are paired to assemble a 7Ah pouch battery according to the negative electrode content (N) and the positive electrode content (P) as N / P=1.1, and the electrolyte used in Example 1 is used as the electrolyte.

Embodiment 3

[0035]Similar to the method in Example 1, the difference is only that (2-trifluoroethoxyethyl) (allyl) sulfite in Example 1 is replaced by (2-pentafluoroethoxyethyl) ( Allyl) sulfite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com