Composite bacteriostatic agent for interior of automobile and preparation method thereof

A bacteriostatic agent and automotive technology, applied in the field of auto parts, can solve problems such as difficult to remove bacteria, explosive growth of bacteria, and inability to effectively solve bacterial infestation, and achieve excellent antibacterial, antibacterial activity, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

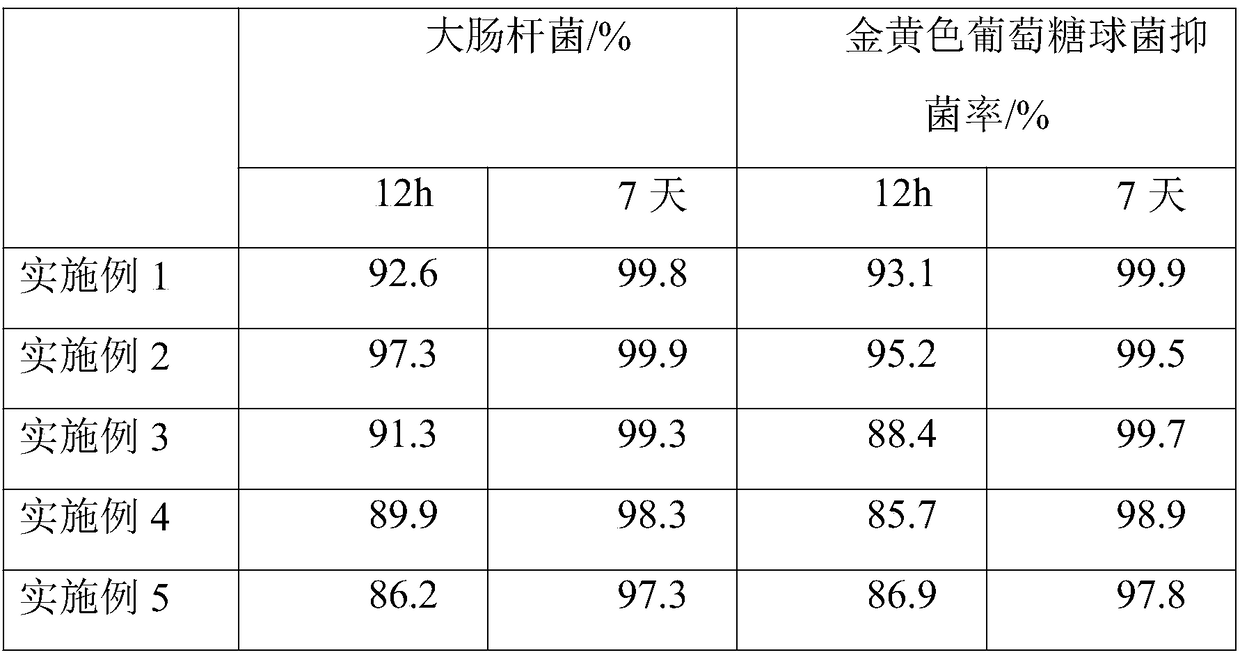

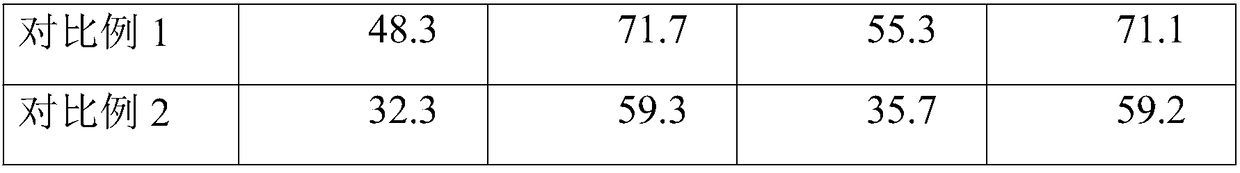

Examples

preparation example Construction

[0019] The present invention also provides a kind of preparation method of the composite antibacterial agent used in automobile interior, comprising the following steps:

[0020] (1) dissolving starch in water, then adjusting the pH of the system to 5.3-6.1 to obtain a starch solution, adding sodium phytate to the starch solution, and stirring for 2-5 hours to obtain starch-sodium phytate nanoparticles;

[0021] (2) Calcining diatomite at 300-500°C for 1-4h to obtain calcined diatomite, then mixing the calcined diatomite, silane coupling agent and starch-sodium phytate nanoparticles in water, and Stirring and reacting at 60-80°C for 0.5-3 hours to obtain modified starch-sodium phytate nanoparticles;

[0022] (3) Ultrasonically disperse graphene oxide in ethanol for 15 to 30 minutes to obtain a graphene suspension, adjust the pH of the system to 7.6 to 8.5, and then add 1-(3-dimethylaminopropyl)-3-ethyl carbon Diimine, N-hydroxysuccinimide and amoxicillin are stirred and react...

Embodiment 1

[0033] A composite bacteriostatic agent for automobile interiors, made of the following parts by weight: 15 parts by weight of diatomite, 5 parts by weight of starch, 10 parts by weight of sodium phytate, 2 parts by weight of silane coupling agent KH5502, graphite oxide 10 parts by weight of amoxicillin, 8 parts by weight of amoxicillin, 8 parts by weight of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide, 5 parts by weight of N-hydroxysuccinimide, 4 parts by weight of glacial acetic acid parts by weight, 8 parts by weight of amino polyethylene glycol, and 5 parts by weight of chitosan.

[0034] Mix amoxicillin with water to prepare amoxicillin solution with a concentration of 0.5mg / mL; mix 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide with water to prepare a concentration of 3mg / mL1-(3-dimethylaminopropyl)-3-ethylcarbodiimide solution; N-hydroxysuccinimide is mixed with water to form a concentration of 1mg / mLN-hydroxysuccinimide solution; graphite Graphene was mixed with etha...

Embodiment 2

[0042] A composite bacteriostatic agent used in automobile interiors, made of the following parts by weight: 20 parts by weight of diatomite, 8 parts by weight of starch, 20 parts by weight of sodium phytate, 3 parts by weight of silane coupling agent KH560, graphite oxide 12 parts by weight of amoxicillin, 5 parts by weight of amoxicillin, 5 parts by weight of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide, 2 parts by weight of N-hydroxysuccinimide, 3 parts by weight of glacial acetic acid parts by weight, 6 parts by weight of amino polyethylene glycol, and 3 parts by weight of chitosan.

[0043] Mix amoxicillin with water to make a concentration of 1 mg / mL amoxicillin solution; mix 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide with water to make a concentration of 2 mg / mL mL1-(3-dimethylaminopropyl)-3-ethylcarbodiimide solution; N-hydroxysuccinimide is mixed with water to make a concentration of 2mg / mLN-hydroxysuccinimide solution; graphene Mix with ethanol to configure a gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com